Contents

OCCUPATIONAL HEALTH AND SAFETY PROGRAMS

G3.1 Occupational health and safety program

G3.1-2 Farm labour contractors and growers

G3.2 Less formal occupational health and safety (OHS) programs

G3.3 Written instructions, training, and supervision: COVID-19 Safety Plan [retired]

CORRECTION OF UNSAFE CONDITIONS

G3.11 Emergency circumstances [retired]

REFUSAL OF UNSAFE WORK

G3.12 Refusal of unsafe work

OCCUPATIONAL FIRST AID

G3.15-1 Nurses acting as first aid attendants in health care settings

G3.15-2 Registered nurses working for health authorities

G3.15(b)-2 Municipal fire departments [retired]

G3.15-3 EMA licence holders working as first aid attendants

G3.15(c) Proof of certification

G3.16 First aid assessment

G3.16(1) Minimum requirements for first aid equipment

G3.16(1)-2 Hospital and acute care facilities

G3.16(2)-2 Automated external defibrillator (AED) [retired]

G3.16(3) Reviewing first aid assessments

G3.16(3.1) Involving workers in first aid assessment

G3.17 Developing and implementing first aid procedures

G3.17(2) Communicating first aid procedures to workers

G3.17(4) Drills

G3.17.1 Air transportation

G3.18(1) Communications

G3.18(2) Availability of first aid attendant

G3.19 First aid records

G3.20 Multiple employer workplaces

G3.21(1) Suspension and cancellation of first aid certificates

G3.21(2) Attendant fit for duty

G3.21(3) First aid attendant responsibilities - Options for discharging responsibilities for care

YOUNG OR NEW WORKERS

G3.23 Young or new worker orientation and training

JOINT HEALTH AND SAFETY COMMITTEES

G3.26 Evaluation of joint committees

G3.27 Minimum training requirements for new joint committee members or worker health and safety representatives

PARTICIPATION IN INVESTIGATIONS

G3.28 Participation in employer incident investigations

Guidelines - Part 3 - Occupational Health and Safety Programs

G3.1 Occupational health and safety program

Issued March 30, 2004; Revised October 26, 2005; Revised May 17, 2006; Editorial Revision February 1, 2008; Editorial Revision February 12, 2009; Revised May 29, 2018; Editorial Revision April 6, 2020; Editorial Revision consequential to November 1, 2024 Regulation Amendment

Regulatory excerpt

Section 3.1 of the OHS Regulation ("Regulation") states:

(1) An occupational health and safety program as outlined in section 3.3 must be initiated and maintained

(a) by each employer that has

(i) a workforce of 20 or more workers, and

(ii) has a hazard rating, within the meaning of section 1(1) of Schedule 3-A, of moderate or high, and

(b) by each employer that has a workforce of 50 or more workers.

(1.1) If subsection (1)(a) or (b) applies to the employer, the occupational health and safety program applies to the whole of the employer's operations.

(2) Despite subsection (1) an occupational health and safety program may be required in any workplace when, in the opinion of an officer, such a program is necessary.

Purpose of guideline

The purpose of this guideline is to:

- Provide criteria for counting workers in an employer's workforce for considering whether an occupational health and safety ("OHS") program is required under section 3.1(1) of the Regulation

- Provide WorkSafeBC prevention officers with factors to consider when exercising their discretion under section 3.1(2)

- Discuss benefits of OHS programs

- Provide additional information on occupational health and safety management systems (OHSMSs).

Criteria for counting workers for the purpose of section 3.1(1)

In determining the number of workers for the purpose of section 3.1(1), the following workers should be considered part of the employer's workforce, regardless of how they or their employers define their status:

- Workers employed for more than one month

- Workers who are employed for less than one month, but have worked for the employer periodically.

Note: Other sections of the Regulation and Workers Compensation Act ("Act") also have requirements that relate to the number of workers. For criteria for counting workers for other requirements, refer to the following:

- OHS Guideline G3.16 First aid assessment

- Prevention Manual Policy Item P2-31-1: Joint Committees - When a Committee is Required

Considerations for prevention officers when exercising their discretion under section 3.1(2)

In addition to those employers who are required to initiate and maintain an OHS program under section 3.1(1), some other types of employers should also initiate and maintain health and safety programs. Section 3.1(2) provides that an OHS program may be required in any workplace when, in the opinion of a prevention officer, such a program is necessary.

A prevention officer who encounters a situation where all of the following conditions are present should consider requiring the employer to initiate and maintain an OHS program pursuant to section 3.1(2) of the Regulation:

- The employer has a workforce of less than 20 workers

- Those workers are exposed to high risks

- An OHS program is essential to the health and safety of workers.

In deciding whether to require an OHS program in the above situation, the prevention officer should consider whether such a program could be effectively initiated and maintained by the employer for each workplace where work is being performed for the benefit of that employer.

Benefits of an OHS program for all workplaces

Even though an employer may not be required to initiate and maintain an OHS program, OHS programs can provide a number of benefits. For example, OHS programs enable an employer to control its occupational health and safety risks, improve health and safety performance, communicate its health and safety commitments and policies to staff, and provide a framework for attaining its health and safety goals and objectives. Further, OHS programs assist with implementation by delineating roles, responsibilities, and accountability for tasks, including checking and corrective action as the program evolves. A properly implemented OHS program can be expected to reduce injuries and the associated costs of disability and lost production hours.

Occupational health and safety management systems

Whether for a small or large employer, occupational health and safety can be managed in the same way that the employer manages other facets of the organization's activities (e.g., quality, production, environment, finances, customer service, etc.). An OHSMS can help organizations reduce or prevent injuries, illnesses, and fatalities in the workplace by providing a framework for corporate behaviour in OHS management. An OHSMS relies on commitment, leadership, and worker participation to achieve its outcomes.

The Canadian Standards Association (CSA), the International Organization for Standardization (ISO), and other standard setting agencies have developed standards establishing minimum requirements and good practices for OHSMSs.

G3.1-2 Farm labour contractors and growers - Responsibilities and OHS programs

Issued July 5, 2007; Editorial Revision February 1, 2008; Editorial Revision January 1, 2009; Editorial Revision consequential to August 4, 2015 Regulatory Amendments; Editorial Revision April 6, 2020; Editorial Revision January 1, 2025

Regulatory excerpt

Responsibilities for worker health and safety are established by the Workers Compensation Act ("Act") and the OHS Regulation ("Regulation"). Farm labour contractors are considered to be the employers of the farm workers they provide to agricultural operations. As such they have responsibilities under the Act, for example in section 21. They also have responsibilities under the Regulation, for example for occupational health and safety programs under section 3.1.

Section 21 of the Act states:

21 General duties of employers

(1) Every employer must:

(a) ensure the health and safety of

(i) all workers working for that employer, and

(ii) any other workers present at a workplace at which that employer's work is being carried out, and

(b) comply with the OHS provisions, the regulations and any applicable orders.

(2) Without limiting subsection (1), an employer must

(a) remedy any workplace conditions that are hazardous to the health or safety of the employer's workers,

(b) ensure that the employer's workers

(i) are made aware of all known or reasonably foreseeable health or safety hazards to which they are likely to be exposed by their work,

(ii) comply with the OHS provisions, the regulations and any applicable orders, and

(iii) are made aware of their rights and duties under the OHS provisions and the regulations,

(c) establish occupational health and safety policies and programs in accordance with the regulations,

(d) provide and maintain in good condition protective equipment, devices and clothing as required by regulation and ensure that these are used by the employer's workers,

(e) provide to the employer's workers the information, instruction, training and supervision necessary to ensure the health and safety of those workers in carrying out their work and to ensure the health and safety of other workers at the workplace,

(f) make a copy of this Act and the regulations readily available for review by the employer's workers and, at each workplace where workers of the employer are regularly employed, post and keep posted a notice advising where the copy is available for review,

(g) consult and cooperate with the joint committees and worker health and safety representatives for workplaces of the employer, and

(h) cooperate with the Board, officers of the Board and any other person carrying out a duty under the OHS provisions or the regulations.

Section 3.1 of the Regulation states:

3.1 When program required

(1) An occupational health and safety program as outlined in section 3.3 must be initiated and maintained

(a) by each employer that has

(i) a workforce of 20 or more workers, and

(ii) at least one workplace that is determined under section 3.16 (2) (b) to create a moderate or high risk of injury, or

(b) by each employer that has a workforce of 50 or more workers.

(1.1) If subsection (1)(a) or (b) applies to the employer, the occupational health and safety program applies to the whole of the employer's operations.

(2) Despite subsection (1) an occupational health and safety program may be required in any workplace when, in the opinion of an officer, such a program is necessary.

Purpose of guideline

The purpose of this guideline is to

- Provide background information on farm labour contractors (FLCs) and their role as employers of farm workers

- Describe circumstances in which the contractor has an obligation to establish a formal occupational health and safety program, and lists the elements that would typically be covered in the programs

- Describe circumstances in which informal programs are required, and what they would include

- Discuss the occupational health and safety responsibilities of growers who use contractors to provide services of farm workers in their operations

- Provide five examples of how the responsibilities of FLCs apply to the protection of farm workers, in comparison to the responsibilities of the grower: worker transport vehicles, personal protective equipment, first aid, protection from hazardous materials, and training

Farm labour contractors and their responsibilities as employers

Farm labour contractors are licensed under the Employment Standards Act. Lists of licensed FLCs are maintained by the Employment Standards Branch at http://www.labour.gov.bc.ca/esb/agriculture/flclist.htm, along with information on the crops serviced and the number of workers for which the FLCs are bonded. In April 2007, about 100 FLCs were listed, bonded for approximately 6,900 workers.

Most FLCs provide services to the vegetable, berry, nursery, and greenhouse sectors, but some deal in other sectors such as poultry, tree fruits, and vineyards. Most are based in the Lower Mainland and Fraser Valley, but a number operate elsewhere, particularly in the Okanagan region.

FLCs are considered employers because of the nature of their contractual arrangements with farm workers. As such they have all the responsibilities of employers under the Act and the Regulation.

When do requirements for formal OHS programs apply?

OHS Guideline G3.1 (Occupational health and safety program) provides detailed information on the application of section 3.1 of the Regulation. It discusses how to count workers for the purposes of determining whether a formal occupational health and safety (OHS) program is required, and outlines considerations that will be used by WorkSafeBC prevention officers when exercising their discretion to require a formal OHS program under section 3.2 of the Regulation. A brief summary of the main points from the guideline is provided below.

Workers are included in the count if they are employed for more than a month. In addition they are included if they have currently worked for less than a month but have previously worked periodically for the employer. As noted in section 3.1(1.1) of the Regulation the count of workers covers all the operations of the employer. This is particularly important to an FLC who provides workers to a number of different farming operations. The count is to include all workers who work for the FLC, not just to those assigned to a particular farming operation.

As noted in section 3.1(1) of the Regulation, if an employer employs workers in at least one moderate or high risk operation there must be a formal OHS program if the total workforce in all operations is 20 workers or more. For all other situations there must be at least 50 workers in the count before a formal OHS program is required. (Most FLCs are bonded for workforces of 20 or more workers and are likely to be involved in at least one moderate risk operation.).

The hazard rating for a farm labour contractor is based on the hazard rating for the farming operations to which the FLC provides the workers. Most of the operations typically serviced by FLCs are moderate risk. Examples include: berry farms, greenhouse operations, vegetable farms, and orchards. In any case where an FLC provides workers to at least one moderate risk operation, the FLC must provide a formal OHS program for all their workers if they have a total workforce of 20 or more workers, regardless of whether the FLC's other workers are engaged in low risk work.

Under section 3.1(2) of the Regulation a prevention officer may require a formal OHS program even if it is not required under section 3.1(1). This may apply where the workforce is less than 20 workers, but the workers are exposed to high risk and it is considered that an OHS program is essential to the health and safety of workers.

(Note that for a grower, the obligations to provide a formal OHS program will also apply at the workplace(s) operated by the grower, depending on the level of risk in the workplace(s) and the total number of workers working in the workplace(s) for the periods of time outlined above.)

What do formal OHS programs include?

Under section 3.3 of the Regulation (Contents of program) the occupational health and safety program must be designed to prevent injuries and occupational diseases, and must include at least the following elements:

- A statement of the employer's aims, and of the responsibilities of the employer, supervisors, and workers.

- Provision for regular inspection of premises, equipment, work methods, and work practices, at appropriate intervals, to ensure that prompt action is undertaken to correct any hazardous conditions found.

- Appropriate written instructions, available for reference by all workers, to supplement the Regulation.

- Provision for the prompt investigation of incidents to determine the action necessary to prevent their recurrence.

- The maintenance of records and statistics, including reports of inspections and incident investigations, with provision for making this information available to the joint committee or worker health and safety representative, as applicable and, on request, to a prevention officer, the union representing the workers at the workplace or, if there is no union, the workers at the workplace.

- Provision by the employer for the instruction and supervision of workers in the safe performance of their work.

- Provision for holding periodic management meetings for the purpose of reviewing health and safety activities and incident trends, and for the determination of necessary courses of action.

An effective program will

- Identify hazards in the workplace

- Control the hazards and eliminate or minimize the potential for workplace injuries or illness

- Be monitored to ensure the program meets its goals and WorkSafeBC requirements under the Act and Regulation

To achieve these objectives the program may need to include additional elements.

What are the requirements for less formal OHS programs in small operations?

These requirements are established by section 3.2 of the Regulation. Such programs must be implemented in all workplaces where formal OHS programs are not required.

The employer has the following three basic responsibilities when implementing and maintaining a less formal program:

- Hold regular monthly meetings with workers for discussion of health and safety matters

- Ensure meetings deal with correction of unsafe conditions and practices and the maintenance of cooperative interest in the health and safety of the workforce

- Maintain a record of the meetings and the matters discussed. This does not mean that formal minutes have to be kept. It is sufficient that a record is kept of when meetings were held, who attended, and the general nature of what was discussed. The record should mention any specific concerns raised by persons attending, and it must be available for inspection by prevention officers

Responsibilities of growers in relation to FLCs

FLCs provide contract labour services to growers. Growers who receive their services also have responsibilities for those workers, typically as employers under section 21(1)(a)(i) & (ii) of the Act and the provisions of the Regulation.

Under section 21 of the Act the grower is responsible for the health and safety of all workers at the grower's workplace, including those of any other employer. Also, depending on the situation, growers may have responsibilities as prime contractors or owners under sections 24 and 25 of the Act respectively.

A prime contractor must

- Ensure that the activities of employers, workers, and other persons at the workplace relating to occupational health and safety are coordinated

- Do everything that is reasonably practicable to establish and maintain a system or process in the workplace that will ensure compliance with the OHS provisions of the Act and the Regulation

An owner must

- Provide and maintain the owner's land and premises that are being used as a workplace in a manner that ensures the health and safety of persons at or near the workplace

- Give to the employer or prime contractor at the workplace the information known to the owner that is necessary to identify and eliminate or control hazards to the health or safety of persons at the workplace

- Comply with the OHS provisions of the Act, the Regulation, and any applicable orders

(Note: Under section 13 of the Act an owner includes not only a person who owns land outright, but also one who is a tenant, lessee, or occupier of the land or premises.)

Examples of the application of OHS requirements to FLCs and growers

The following examples will assist with an understanding of the application of occupational health and safety requirements to FLCs, and growers who contract for their services.

1. Worker transport vehicles: These are typically owned and operated by FLCs. As such FLCs are responsible for all aspects of safety of the vehicle including condition, maintenance, operation, and use. Requirements apply under provisions such as Part 17 (Worker transportation) of the Regulation, and those under the Motor Vehicle Act.

Growers who contract with FLCs are expected to exercise an oversight function when the vehicle arrives on site. Should they observe any faulty condition of the vehicle or unsafe operation they should draw it to the attention of the FLC to ensure it is corrected. In addition, as owners, the growers have a responsibility to make sure that the site is safe, including any roadway to be used by the worker transport vehicle operated by the FLC.

2. Personal protective equipment (PPE): Part 8 (Personal Protective Clothing and Equipment) of the Regulation provides the applicable requirements. Section 8.2 outlines the obligations of workers and employers. Generally, workers are expected to provide clothing for protection against the natural elements such as weather, and general purpose work gloves, footwear, and safety headgear if needed. However, the Regulation also recognizes that an employer may provide any or all of these items.

An employer must provide any other PPE required for the protection of workers. This might include protective gloves, clothing, or respirators if workers may be exposed to pesticides or other harmful materials, and hearing protection if workers will be working near noisy equipment. Typically, the grower controls the circumstances where workers may be at risk on the worksite and would have the expertise on appropriate PPE. In such cases, the grower would have a primary responsibility for provision of such equipment, but the FLC shares in that responsibility.

3. First aid: Under the requirements for first aid in Part 3 (Rights and Responsibilities) of the Regulation, the FLC is responsible for ensuring the provision of first aid for farm workers in their employ. First aid equipment must be provided on worker transport vehicles as required by section 17.10 (Vehicle design), as well as appropriate fire extinguishers. Typically the equipment required will be a basic first aid kit, except where a very small number of workers are transported, in which case a personal kit may be sufficient. A written first aid assessment for worker transport vehicles is also required.

Once workers have been transported to a worksite, the first aid requirements are likely to change, as many agricultural worksites are assigned at least a moderate hazard rating. A separate first aid assessment must be completed for the worksite, and first aid supplies for the FLC's workers must be adjusted accordingly. If the grower employs workers other than those provided by the FLC, then the first aid for the site needs to take account of the total number of workers on site. FLCs are also responsible for ensuring each workplace conducts an annual first aid drill, as required by section 3.17(4) of the Regulation.

As previously mentioned, the grower typically has employer responsibilities on site for workers provided by the farm labour contractor. If in a particular situation the grower is a prime contractor (refer to section 24 of the Act), then section 3.20 of the Regulation requires the grower to do everything that is reasonably practicable to establish and maintain the necessary first aid capability on the site. Unless there is an unusual circumstance, such as a short term situation in which the FLC provides more workers than was originally requested, it will be considered practicable for the grower to provide first aid that covers all workers on site.

4. Protection from hazardous materials: Typically workers employed by FLCs carry out activities such as pruning, thinning, and harvesting. In most cases, if there are hazardous materials present in a workplace, then they are likely to be under the control of the grower.

Under their responsibilities as both owners and employers, growers are required to maintain a safe site, and ensure that FLCs are given the information needed to ensure the safety of the FLC's workers.

Information requirements on hazardous materials are covered primarily in Part 5 (Chemical Agents and Biological Agents) of the Regulation. Most substances to which a worker might be exposed in an agricultural operation (such as many pesticides, corrosive cleaning agents, and fertilizers) are covered by the Workplace Hazardous Materials Information System (WHMIS), which is addressed in sections 5.3 to 5.18. For hazardous substances not covered by WHMIS, such as decomposition gases from silos and manure pits, section 5.2 will apply. Other provisions in Part 5 cover issues such as storage, exposure limits, ventilation, and hazardous wastes.Part 6 (Substance Specific Requirements) of the Regulation covers requirements for specific groups of substances; for example, pesticides. Among other things, the employer must ensure that pesticides are stored and used safely, are applied by a qualified person, that restricted entry intervals are established after application of a pesticide and appropriate warning signs are posted, and that proper hygiene facilities are provided. In most cases these measures will be the responsibility of the grower.

Restricted entry intervals prohibit entry by a worker into an area in which pesticides are applied unless a worker is properly protected before he/she enters the area. Workers must be protected both before and after the expiry of the entry intervals. The party that controls the use of pesticides on site, typically the grower, has responsibilities to protect workers under these provisions. In addition they have the responsibility to communicate to the FLC all information needed to ensure the safety of the FLC's workers. Depending on the arrangements made between the grower and the FLC, one or both of the parties will be responsible for providing necessary information to workers, and any necessary personal protective equipment that is not the responsibility of the worker under section 8.2 of the Regulation.

5. Training: Under section 21(2) of the Act, an employer has the responsibility to ensure workers are made aware of all known or reasonably foreseeable hazards, as well as their rights and duties under the Act and Regulation, and are provided with the information, instruction, training, and supervision to ensure their health and safety. A number of specific training requirements are covered in the Regulation. Three examples are provided below.

5.1 Orientation: Effective July 26, 2007 under sections 3.22 to 3.25 of the Regulation all young and new workers must receive orientation and training specific to the workplace. New workers include workers who are relocated to a new workplace if the hazards in that workplace are different from the hazards in their previous workplace. These provisions will have substantial application to FLCs in the agriculture sector given that their workers are often assigned to new workplaces. Again, responsibilities may be shared between the grower and FLC on how the various specified training and orientation elements are addressed. It may, for example, be reasonable to expect that the FLC take the lead on providing generic instruction on topics that are not site-specific, with the grower taking responsibility for site specific topics. Records must be kept of the orientation and training provided.

5.2 WHMIS: For hazardous substances covered by WHMIS, the worker must receive the education and training required by sections 5.6 and 5.7 of the Regulation. Section 5.6 deals with general (generic) requirements to ensure workers know among other things the elements of the WHMIS program, and the content required on labels and safety data sheets (SDS). Section 5.7 addresses site-specific requirements for training in the safe procedures for hazardous products in the workplace.

Again, the FLC and grower may, depending on the arrangements between them, share in the responsibilities for both generic instruction and site-specific training. It may be a typical scenario for the FLC to ensure generic instruction is given, and the grower to cover site-specific training. In the final analysis, the worker must be able to answer the following four questions:

- What are the hazards of the materials to which I may be exposed?

- How am I protected from those hazards?

- What do I do in the event of an emergency?

- Where do I get more detailed information?

5.3 Forklifts and other on-site equipment: Typically any such equipment is under the control of the grower. Therefore, it will be the grower who has the basic responsibility to ensure workers are trained in the use of the equipment should they be required to operate it, and in the safe procedures to follow for workers who are working in the vicinity of the equipment. The FLC has a responsibility to ensure that adequate training has been provided.

5.4 FLC vehicles: The FLC is responsible for instruction of workers in the use of FLC vehicles used for transporting farm workers to and from the grower's operation. This would include, for example, instruction for the operator in the requirements of the pre-shift vehicle inspection, and for the operator and workers being transported, instruction in the proper procedures to follow in the vehicle, such as the procedures for the transport of materials and tools, and the use of seat belts.

G3.2 Less formal occupational health and safety (OHS) programs

Issued October 26, 2005; Revised May 17, 2006; Editorial Revision February 1, 2008; Revised May 29, 2018; Editorial Revision April 6, 2020

Regulatory excerpt

Section 3.1 of the OHS Regulation ("Regulation") states:

(1) An occupational health and safety program as outlined in section 3.3 must be initiated and maintained

(a) by each employer that has

(i) a workforce of 20 or more workers, and

(ii) at least one workplace that is determined under section 3.16 (2)(b) to create a moderate or high risk of injury, or

(b) by each employer that has a workforce of 50 or more workers.

(1.1) If subsection (1)(a) or (b) applies to the employer, the occupational health and safety program applies to the whole of the employer's operations.

(2) Despite subsection (1) an occupational health and safety program may be required in any workplace when, in the opinion of an officer, such a program is necessary.

Section 3.2 of the Regulation states:

In any operation where the workforce is less than that referred to in section 3.1(1) the employer must

(a) initiate and maintain a less formal program based on regular monthly meetings with workers for discussion of health and safety matters,

(b) ensure that meetings are directed to matters concerning the correction of unsafe conditions and practices and the maintenance of cooperative interest in the health and safety of the workforce, and

(c) maintain a record of the meetings and the matters discussed.

Purpose of guideline

The purpose of this guideline is to provide guidance around the following:

- Record keeping requirements for less formal occupational health and safety programs (OHS programs)

- Situations where employers are required to implement a less formal program under section 3.2, and to establish and maintain a joint health and safety committee pursuant to section 31 of the Workers Compensation Act ("Act")

Requirement for less formal programs

Section 3.2(a) requires that the employer or a person delegated by the employer calls, at least once a month, a meeting of workers present at that time. The employer's obligation under section 3.2(c) to maintain a "record of the meetings" does not mean that formal minutes have to be kept. It is sufficient that a record is kept of when meetings were held, who attended and the general nature of what was discussed. The record should mention any specific concerns raised by persons attending. The record must be available for inspection by WorkSafeBC prevention officers.

OHS programs, less formal programs, and joint health and safety committees

Section 3.2 of the Regulation requires that a less formal program be initiated and maintained in any operation where the workforce is less than that referred to in section 3.1(1) of the Regulation. In such situations, an employer may also be required to establish and maintain a joint health and safety committee under section 31 of the Act.

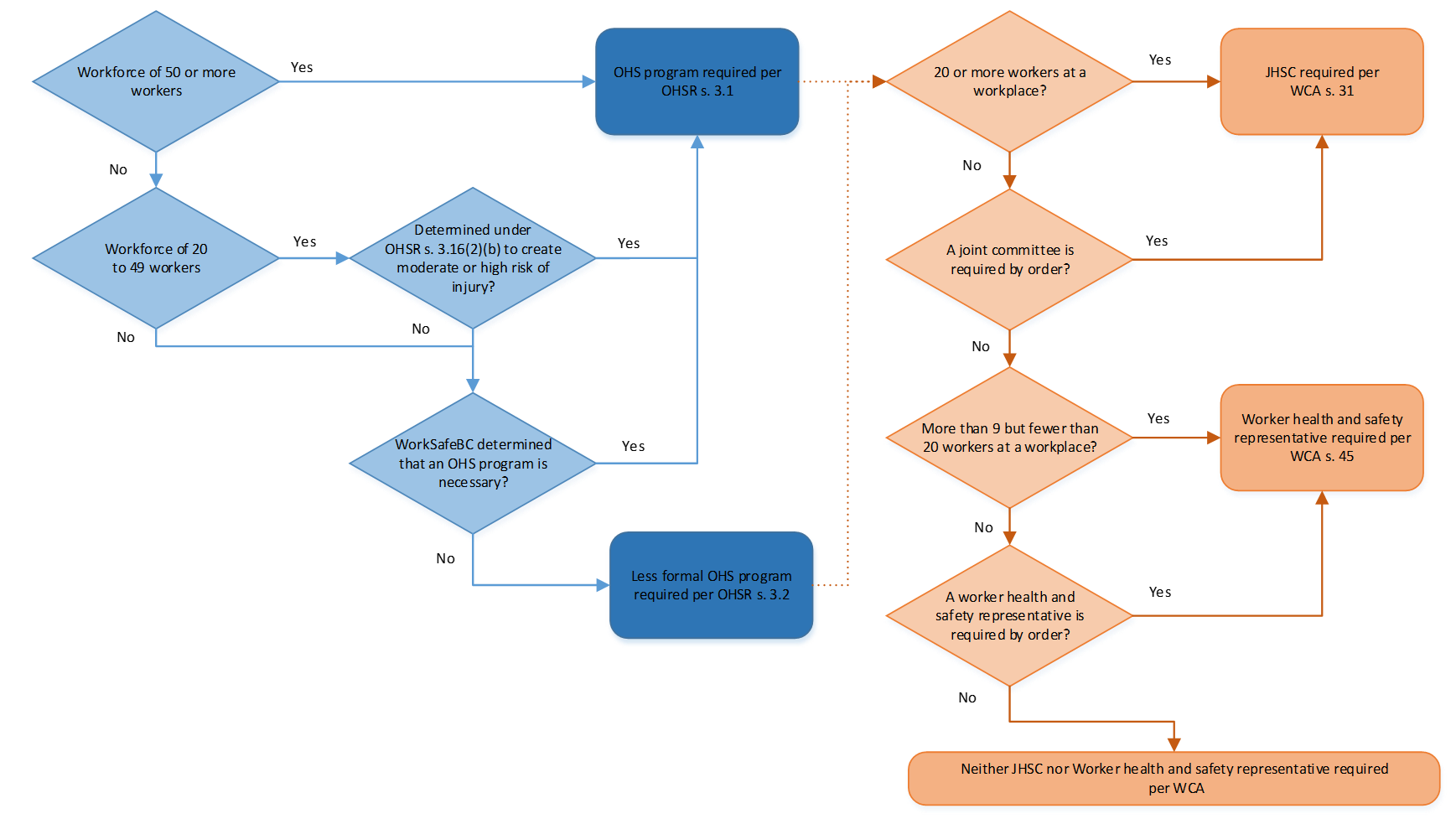

The following diagram sets out the requirements for OHS programs, joint health and safety committees and worker health and safety representatives. Additional requirements around joint health and safety committees and worker health and safety representatives are set out in Division 4 of the Act.

G3.3 Written instructions, training, and supervision: COVID-19 Safety Plan

Issued June 10, 2020; Revised June 22, 2020; Retired July 1, 2021

This guideline is no longer needed.

Guidelines - Part 3 - Correction of Unsafe Conditions

G3.11 Emergency circumstances

Issued August 1, 1999; Retired November 13, 2020

This guideline has been retired as it contained outdated or redundant material.

Guidelines - Part 3 - Refusal of Unsafe Work

G3.12 Refusal of unsafe work

Issued August 1, 1999; Revised September 21, 2011; Editorial Revision December 15, 2017; Editorial Revision April 6, 2020; Revised consequential to August 22, 2022 Regulatory Amendment

Regulatory excerpt

Section 3.12 of the OHS Regulation ("Regulation") states:

(1) A person must not carry out or cause to be carried out any work process or operate or cause to be operated any tool, appliance or equipment if that person has reasonable cause to believe that to do so would create an undue hazard to the health and safety of any person.

(2) A worker who refuses to carry out a work process or operate a tool, appliance or equipment pursuant to subsection (1) must immediately report the circumstances of the unsafe condition to the worker's supervisor or employer.

(3) A supervisor or employer receiving a report made under subsection (2) must immediately investigate the matter and

(a) ensure that any unsafe condition is remedied without delay, or

(b) if, in the supervisor's or employer's opinion, the report is not valid, must so inform the person who made the report.

(4) If the procedure under subsection (3) does not resolve the matter and the worker continues to refuse to carry out the work process or operate the tool, appliance or equipment, the supervisor or employer must investigate the matter in the presence of the worker who made the report and in the presence of

(a) a worker member of the joint committee,

(b) a worker who is selected by a trade union representing the worker, or

(c) if there is no joint committee or the worker is not represented by a trade union, any other reasonably available worker selected by the worker.

(5) If the investigation under subsection (4) does not resolve the matter and the worker continues to refuse to carry out the work process or operate the tool, appliance or equipment, both the supervisor, or the employer, and the worker must immediately notify an officer, who must investigate the matter without undue delay and issue whatever orders are deemed necessary.

Section 3.12.1 of the Regulation states:

If a worker refuses work under section 3.12, the employer must not require or permit another worker to do the refused work unless

(a) the matter has been resolved under section 3.12(3), (4) or (5), or

(b) the employer has, in writing, advised the other worker and a person referred to in section 3.12(4)(a), (b) or (c) of all of the following:

(i) the refusal;

(ii) the unsafe condition reported under section 3.12(2);

(iii) the reasons why the work would not create an undue hazard to the health and safety of the other worker or any other person;

(iv) the right of the other worker under section 3.12 to refuse unsafe work.

Section 3.13 of the Regulation states:

(1) A worker must not be subject to prohibited action as defined in section 47 of the OHS provisions of the Workers Compensation Act because the worker has acted in compliance with section 3.12 or with an order made by an officer.

(2) Temporary assignment to alternative work at no loss in pay to the worker until the matter in section 3.12 is resolved under section 3.12(3), (4) or (5) is deemed not to constitute prohibited action.

Section 4.19 of the Regulation states:

(1) A worker with a physical or mental impairment which may affect the worker's ability to safely perform assigned work must inform the worker's supervisor or employer of the impairment, and must not knowingly do work where the impairment may create an undue risk to the worker or anyone else.

(2) A worker must not be assigned to activities where a reported or observed impairment may create an undue risk to the worker or anyone else.

Section 13 of the Workers Compensation Act ("Act") states:

"worker representative" means,

(a) in relation to a workplace for which there is a joint committee, a worker representative on the committee, and

(b) in relation to a workplace for which there is a worker health and safety representative, that representative;

Purpose of guideline

The purpose of this guideline is to:

- Explain the test for determining whether there is reasonable cause to believe that a work process, or the operation of a tool, appliance, or equipment, would create an undue hazard to the health and safety of a person

- Provide guidance on the steps for reporting and responding to a work refusal

- Provide guidance on distinguishing between:

- Reporting unsafe conditions under section 3.10

- Reporting work refused under section 3.12

- Reporting physical or mental impairment under section 4.19

- Provide information about how an employer can advise a worker, in writing, of a previous relevant work refusal

Refusing unsafe work

Refusing to carry out unsafe work is a responsibility of every person at the workplace. The refusal of unsafe work is generally accepted as one of the three main rights of workers, along with the right to know about health and safety matters in the workplace and the right to participate in health and safety activities at work.

A fundamental purpose of the OHS Provisions of the Workers Compensation Act is to protect workers and other people at the workplace from occupational health and safety hazards. Employers, workers, and other people at the workplace all share in the responsibility of ensuring the health and safety of people at or near the workplace.

Employers are responsible for ensuring workers are aware of any known or reasonably foreseeable health and safety hazards. Employers must also correct hazardous conditions. Workers, for their part, must take reasonable care to protect their own health and safety and the health and safety of other people who may be affected by what they do at work.

A worker who reasonably believes that work creates an undue hazard must refuse to do that work. This includes any work process, or the use or operation of a tool, machine, or piece of equipment.

A worker who is refusing unsafe work should clearly inform the supervisor or employer that they are refusing the work as unsafe, rather than simply reporting an unsafe condition. Similarly, an employer or supervisor who is informed of an unsafe condition should confirm with the worker whether the worker is refusing the work as unsafe.

Elements of the right to refuse

Section 3.12 of the Regulation provides a formal procedure for refusing unsafe work. The purpose of this section is to ensure workers and employers work together to address a worker's reasonably held belief that work presents an undue hazard.

This section requires a worker to immediately report the unsafe circumstances to their employer, who must immediately investigate. If the matter is not resolved by this reporting, section 3.12(4) of the Regulation requires the employer to involve both the worker and another designated person in their investigation. The final step involves contacting WorkSafeBC, who will assign a prevention officer who will ensure the steps were followed and make a determination should the employer and worker be unable to resolve the matter. The steps in this process must be followed; doing so helps to ensure worker engagement and promote consultation and collaboration when resolving a potentially unsafe working condition.

"Reasonable cause to believe"

The Regulation establishes what is commonly referred to as a "reasonable person test." The test is objective: How would a reasonable person, dispassionate, and fully apprised of the circumstances of the matter, interpret the situation?

A reasonably held belief is generally formed by the worker at the time of the work refusal, based on the relevant and available information at the time, and exercising good faith judgment. Whether or not that reasonably held belief is substantiated will generally be determined after following the steps below and investigating the matter.

"Undue hazard"

The term "undue hazard" incorporates each of the following elements:

- "Hazard" is defined in section 1.1 of the Regulation to mean "a thing or condition that may expose a person to a risk of injury or occupational disease."

- "Risk" is defined in section 1.1 as "a chance of injury or occupational disease."

- "Undue" is generally accepted as meaning something that is unwarranted, inappropriate, excessive, or disproportionate.

Work that may reasonably be perceived as creating an undue hazard includes a thing or condition that may expose a person to an unwarranted, inappropriate, excessive, or disproportionate risk of injury or occupational disease. An undue hazard is something more than unusual or unexpected; however, it would generally be understood as a hazard that creates an unacceptable, unreasonable, or unnecessary health and safety risk to a person at the workplace.

Reasonable cause to believe work creates an undue hazard

The belief that work will create an undue hazard is therefore more than a generalized concern or feeling of uncomfortableness. When a worker refuses work on account of a reasonable belief — in other words an objective reason refusing work as unsafe to the point of presenting an undue hazard — the employer is required to follow the steps set out in the Regulation to resolve the matter.

Steps for investigating refusal of unsafe work

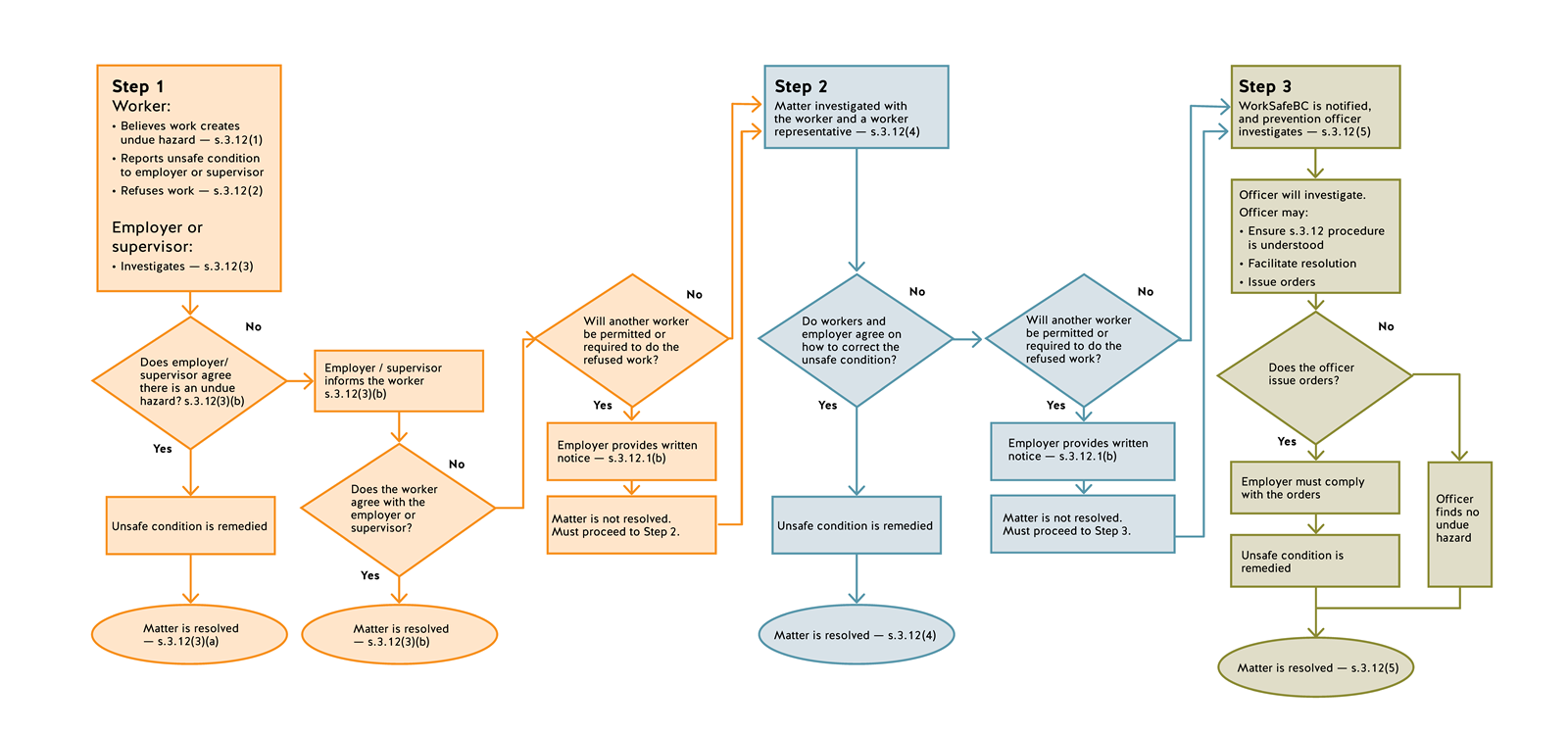

When a worker refuses work as unsafe, the employer or supervisor receiving the report must immediately investigate the matter. Section 3.12 of the Regulation sets out three steps in the process for reporting, investigating, and resolving a refusal of unsafe work. A work refusal can be resolved at any of these steps. Reasonable effort should be made by workers and employers to work through the following steps as soon as possible to find a mutually satisfactory resolution.

Step 1

A worker who believes a work process, tool, or equipment would create an undue hazard for themselves or others must refuse unsafe work, and immediately report that unsafe or harmful condition to the supervisor or employer. The supervisor or employer must then immediately investigate the matter.

Where the supervisor and employer agree that the work is unsafe, they must ensure the unsafe condition is remedied without delay. However, should the supervisor or employer investigate and disagree with the worker, they must inform the worker of their opinion.

The matter will be resolved under section 3.12(3) of the Regulation when the worker, supervisor, and employer agree that either of the following apply:

- The unsafe condition has been remedied

- There is no unsafe condition

When the supervisor and employer are of the opinion that there is no unsafe condition, but the worker continues to refuse the work as unsafe, the investigation must proceed to step 2.

The employer or supervisor may permit another worker to do the refused work only if:

- The task would not create an undue hazard to the health and safety of the other worker or any other person

- The other worker is provided with written notice, in accordance with section 3.12.1 of the Regulation

Step 2

If the matter is not resolved under section 3.12(3) of the Regulation, and the worker continues to refuse the work as unsafe, the supervisor or employer must investigate the matter again, accompanied by the worker who made the report as well as a worker representative, a worker selected by the union, or a worker selected by the worker who made the report of unsafe work, as applicable.

In workplaces where there is a joint health and safety committee, the committee should consider establishing rules of procedure around contacting a worker representative to participate in the work refusal process. If no worker representative is reasonably available, another worker who was designated as an alternate by a worker representative may participate (refer to section 46 of the Act).

The matter will be resolved under section 3.12(4) of the Regulation when the workers, supervisor, and employer agree that either of the following apply:

- The unsafe condition has been remedied

- There is no unsafe condition

When there continues to be a difference of opinion about the unsafe condition, the investigation must proceed to step 3 of the process.

The employer or supervisor may permit another worker to do the refused work only if:

- The task would not create an undue hazard to the health and safety of the other worker or any other person

- The other worker is provided with written notice, in accordance with section 3.12.1 of the Regulation

Step 3

If the matter is not resolved under section 3.12(4) of the Regulation, both the supervisor or the employer and the worker who is refusing work must immediately notify WorkSafeBC. A prevention officer will then investigate and take steps to resolve the matter.

A prevention officer investigating a work refusal under section 3.12(5) of the Regulation will generally begin by ensuring that the employer and workers have followed all the steps set out above. When they have not, the prevention officer will go over the process with them and ask them to try and resolve the matter themselves.

When the worker, employer, and supervisor are unable to resolve the matter themselves, the prevention officer will inspect the workplace, including the tools, appliance, equipment, machinery, work methods, and/or work process associated with the work refusal.

The prevention officer will document their findings in an inspection report, and will issue compliance orders where necessary. This may include the issuance of a stop use order or stop work order, as described in OHS Guideline G-P2-89.

When the prevention officer determines that there is no undue hazard, they will inform the worker and employer, and include the information in the inspection report.

The prevention officer will advise the parties of the requirement of section 3.13 of the Regulation that "A worker must not be subject to prohibited action as defined in section 47 of the Workers Compensation Act because the worker has acted in compliance with section 3.12 or with an order made by a prevention officer." When a prevention officer determines that there is no undue hazard, and a worker continues to refuse work as unsafe, the worker is no longer protected by the provisions of section 3.13 of the Regulation.

Any person affected by a decision of a prevention officer — including an employer, worker, owner, supplier, or union — may ask the Review Division of WorkSafeBC to conduct a review. For more information about the review process, visit Submitting a request for review.

Reassignment of refused work

Using a tool, appliance, or equipment, or following a work process, may present an undue hazard to one worker, but not to another worker — for example, if one worker has training or experience that another does not. This work may be reassigned.

Alternately, a worker may refuse work as unsafe, and the employer or supervisor may disagree that the work presents an undue hazard. The employer may ask another worker to do the work while the investigation into the refusal is ongoing. In these situations, the employer must provide written notice of the refusal to any subsequent worker who is instructed or permitted to do the work.

When the matter is resolved

Written notice of refused work is not required when the matter has been resolved. The matter may be resolved by any of the following sections of the Regulation:

- Section 3.12(3)(a): The unsafe condition has been corrected

- Section 3.12(3)(b): The employer or supervisor investigated, determined that there was no undue hazard (was of the opinion the report was not valid), informed the worker of their finding, and the worker agreed

- Section 3.12(4): The employer or supervisor investigated, accompanied by the worker who made the report and another specified worker; either the unsafe condition was remedied or the workers were satisfied there was no longer an undue hazard

- Section 3.12(5): A prevention officer has investigated and the matter was resolved

Written notice

"The other worker"

When a worker has reported work as unsafe, the employer must not require or permit another worker to do the refused work unless the matter is resolved, as described above, or the other worker is given written notice of the work refusal. Workers who must be given written notice of a work refusal include any worker assigned to replace the worker who reported unsafe work, as well as any worker resuming work after a work refusal, such as a worker on a subsequent shift.

The Regulation requires that, in addition to any other worker who may be required or permitted to do the refused work, the employer must also advise the following people, as applicable:

- A worker member of the joint committee

- A worker who is selected by a trade union representing the worker

- If there is no joint committee or the worker is not represented by a trade union, any other reasonably available worker selected by the worker

Advising in writing

There are several reasons for providing notice in writing. These include:

- Giving the subsequent worker the opportunity to make an informed decision about whether the task is safe for them

- Ensuring the information is effectively communicated to workers

- Maintaining records of work refusals to monitor trends and inform changes in policies and procedures

- Demonstrating due diligence and compliance with the regulatory requirements

- Ensuring all workers know they have the right to refuse the work as unsafe

Employers should consider their needs when choosing how to advise workers of a work refusal. Considerations may include the number of workers to be advised and the need to retain records. Examples of types of written notice include:

- Electronic communication, such as email, text message, or electronic communication system

- Paper records, such as forms or a logbook

- Worker communication board or collaboration forum, such as a white board or notice board

The employer may use a combination of ways to communicate. For example, the information could be documented in a logbook, a photograph of the logbook could be sent in a text or email, and the photograph could be included in any reports or documentation used by the employer. The employer should be able to demonstrate that the way in which they have provided written notice to workers was effective.

Contents of the written notice

The Regulation requires the following information be provided:

- The fact that a worker refused work as unsafe

- The details of the work process, tool, appliance, or equipment that was reported to create an undue hazard

- Reasons why the task would not create an undue hazard to the health and safety of the other worker or any other person

- The right of any other worker to refuse unsafe work

The employer may choose to include additional information, such as steps that are being taken to correct the unsafe condition.

Related regulatory provisions

The following sections of the Regulation may overlap or converge with the work refusal process. When this occurs, workers and employers should keep in mind that the large and liberal application of the work refusal process supports the purpose of section 3.12, and promotes worker engagement in workplace health and safety matters.

Reporting unsafe conditions under section 3.10

A person who observes what appears to be an unsafe or harmful condition or act at a workplace must report it as soon as possible. Reporting unsafe conditions under section 3.10 may progress to a work refusal when a worker is required to carry out work that they have reasonable cause to believe would create an undue hazard.

Emergency action to correct an immediate threat under section 3.11

Circumstances may arise where emergency action is required to correct a condition that constitutes an immediate threat to workers. In these cases, every possible effort must be made to correct the hazard while the minimum number of qualified and properly instructed workers work to correct the unsafe condition.

Reporting physical or mental impairment under section 4.19

Some workers may have an underlying condition that would lead them to suffer an illness or sustain an injury, even though others would not be affected in the same way. A worker with a physical or mental impairment that may affect the worker's ability to safely perform assigned work is required by section 4.19 of the Regulation to inform their supervisor or employer of the impairment.

In the Workers Compensation Appeals Tribunal Noteworthy Decision WCAT-2011-00503, the panel's vice-chair considered the differences between the regulatory requirements for refusing unsafe work and reporting impairment. The vice-chair determined that there is a difference between an employer's obligations when dealing with a generally unsafe workplace and one that is unsafe to a particular worker only because of the worker's physical or mental impairment. This was because sections 3.9 through 3.13 of the Regulation focus on work processes, conditions, or equipment in the workplace that are in and of themselves harmful or unsafe to operate or carry out.

A worker's reporting of a physical or mental impairment under section 4.19 does not trigger a work refusal under section 3.12 or require the employer investigate it under sections 3.12(3) and (4). However, if an employer continues to instruct the worker to perform the assigned work, and the worker has reasonable grounds to believe the worker's impairment will create an undue hazard, the worker must refuse to perform that work. At this point, the refusal does constitute a work refusal under section 3.12.

The worker and employer should work together, having consideration for facts and circumstances of each situation, to ensure that health and safety hazards are addressed. The employer may need to consider how to accommodate a worker's physical or mental impairment, while also recognizing a worker's right to privacy around a personal or medical condition.

Guidelines - Part 3 - Occupational First Aid

G3.15-1 Nurses acting as first aid attendants in health care facilities (formerly G3.15(b)-1)

Issued September 6, 2018; Editorial Revision consequential to November 1, 2024 Regulatory Amendment; Editorial Revision July 10, 2025

Regulatory excerpt

Section 3.15 of the OHS Regulation ("Regulation") states:

The employer must ensure that a person who is designated as a first aid attendant

(a) is at least 16 years old,

(b) [Repealed]

(c) has a first aid certificate in good standing at the required level issued by the Board or a person recognized by the Board, and

(d) meets any other requirements determined by the Board for designation as a first aid attendant.

Purpose of guideline

The purpose of this guideline is to outline the conditions under which a WorkSafeBC-approved first aid training provider may issue an intermediate first aid certificate to a registered nurse or registered psychiatric nurse, without requiring the nurse to first attend an occupational first aid training course. (Refer to OHS Guideline G3.15-2 for alternative guidance for nurses working for B.C. health authorities.)

Requirement

WorkSafeBC-approved first aid training providers may issue an intermediate first aid certificate to a registered nurse or registered psychiatric nurse on receipt of a written request from an employer offering health care services confirming that:

- The individual is currently employed, primarily as a practicing nurse, and holds a valid license issued by the BC College of Nurses and Midwives (BCCNM)

- The nurse has reviewed and completed the WorkSafeBC jurisprudence package or received other equivalent training

- The nurse has successfully completed a Basic Life Support course within the past 3 years

The intermediate first aid certificates issued to nurses are not transferable to other industries.

Nurses are obligated by the professional standard of their licence to function only within their level of competence. Employers that wish to utilize registered nurses as first aid attendants under this provision must first ensure the nurse:

- Is willing to act in the capacity of a first aid attendant

- Confirms they have been trained in the knowledge and skills associated with intermediate first aid attendants*

- Has operational capacity to fulfil the duties required by section 3.21 of the Regulation

* Skills and competencies for intermediate first aid attendants can be found in Appendix G of the jurisprudence package.

G3.15-2 Registered nurses working for health authorities

Issued consequential to November 1, 2024 Regulatory Amendment; Editorial Revision July 10, 2025

Regulatory excerpt

Section 3.15 of the OHS Regulation ("Regulation") states:

The employer must ensure that a person who is designated as a first aid attendant

(a) is at least 16 years old,

(b) [Repealed]

(c) has a first aid certificate in good standing at the required level issued by the Board or a person recognized by the Board, and

(d) meets any other requirements determined by the Board for designation as a first aid attendant.

Purpose of guideline

The purpose of this guideline is to enable nurses to act as intermediate first aid attendants in specific health care facilities, without a first aid certificate. This guideline outlines the requirements under which WorkSafeBC will accept a nurse's licence as an alternative acceptable first aid credential.

Acceptance of registered nurse and registered psychiatric nurse licences as intermediate first aid certificates in limited health care settings

Registered nurses (RNs) and registered psychiatric nurses (RPNs) are trained in wound care and basic lifesaving interventions as part of the licensing competencies required by the British Columbia College of Nurses and Midwives (BCCNM).

WorkSafeBC has entered into arrangements with the B.C. health authorities and Providence Health Care, as permitted by section 55 of the Workers Compensation Act, to recognize BCCNM licences as first aid certificates in limited health care locations directly operated by these specific employers. This provision applies only to the following health care workplaces:

- Acute care workplaces assigned to WorkSafeBC classification unit 766001

- Long-term care workplaces assigned to WorkSafeBC classification unit 7660011

- Short-term care workplaces assigned to WorkSafeBC classification unit 766019

- Remote clinics operated by the First Nations Health Authority

This provision does not apply to health care locations operated by other employers or other classification units.

Requirement

Health authorities may utilize RNs or RPNs as occupational first aid attendants — intermediate level — in health care locations directly operated by a health authority or Providence Health Care. To use nurses as first aid attendants, the health authority or its delegate must document that the respective nurse meets and maintains all of the following requirements:

- Holds a valid RN or RPN licence from the British Columbia College of Nurses and Midwives

- Has reviewed and completed the jurisprudence package or completed other training that covers the topics outlined in the jurisprudence package prior to commencing work as a first aid attendant

- Has completed a Basic Life Support course within the past 3 years

Nurses are obligated by the professional standard of their licence to function only within their level of competence. Employers that wish to utilize registered nurses as first aid attendants under this provision must also ensure the nurse:

- Agrees to act in the capacity of a first aid attendant

- Confirms they have been trained in the knowledge and skills associated with intermediate first aid attendants*

- Has operational capacity to fulfil the duties required by section 3.21 of the Regulation

* Skills and competencies for intermediate first aid attendants can be found in Appendix G of the jurisprudence package. Nurses are obligated by the professional standard of their licence to function only within their level of competence.

Health authority employers operating under this guidance are expected to implement an effective system to ensure these requirements are maintained for as long as the nurse is expected to provide first aid services to workers.

At the request of a WorkSafeBC officer, an employer must produce documentation verifying that the respective RN has met the requirements for licence recognition. This may be in the form of a letter from a health authority or its delegate.

Health care services providers that use nurses as first aid attendants must comply with all other first aid requirements under the Regulation, including designating first aid attendants and developing written first aid procedures.

Suspending or revoking acceptance of alternative licences

WorkSafeBC may revoke the acceptance of an individual BCCNM licence holder as a first aid attendant without impacting the validity of their medical licence. Medical licences issued by BCCNM may only be revoked or suspended by BCCNM. Practice concerns that come to the attention of WorkSafeBC will be referred to the licensing board for investigation and appropriate remedy.

Refer to OHS Guideline G3.21(1) for additional details.

G3.15(b)-2 Municipal fire departments

Issued September 6, 2018; Retired November 1, 2024

This guideline is now incorporated in G3.15-3.

G3.15-3 EMA licence holders working as first aid attendants (formerly G3.15(b)-2 and G3.15(b)-3)

Issued September 6, 2018; Revised consequential to November 1, 2024 Regulatory Amendment; Editorial Revision July 10, 2025

Regulatory excerpt

Section 3.15 of the OHS Regulation ("Regulation") states, in part:

The employer must ensure that a person who is designated as a first aid attendant

…

(c) has a first aid certificate in good standing at the required level issued by the Board or a person recognized by the Board, and

(d) meets any other requirements determined by the Board for designation as a first aid attendant.

…

Purpose of guideline

The purpose of this guideline is to enable Emergency Medical Assistant (EMA) licence holders to act as first aid attendants, without a first aid certificate issued by WorkSafeBC or a person recognized by WorkSafeBC. This guideline outlines the requirements under which WorkSafeBC will accept a licence issued by the Emergency Medical Assistants Licensing Board (EMALB) as an alternative acceptable first aid credential.

Acceptance of Emergency Medical Assistant (EMA) licences as first aid certificates

Wound care and basic lifesaving interventions are included in the licensing competencies required by the British Columbia Emergency Medical Assistance Licensing Board (EMALB).

The scope of practice for EMAs includes the first aid competencies outlined in CSA Z1210-17 First aid training for the workplace — curriculum and quality management for training agencies.

WorkSafeBC has entered into arrangements with the Emergency Medical Assistant Licensing Board (EMALB) as permitted by section 55 of the Act. Recognition of EMALB licences as an alternative first aid credential is permitted in all occupational settings, under the conditions outlined below.

Requirement

The following EMA licences are recognized alternative qualifications for occupational first aid attendants:

- First Responder (EMA FR) — intermediate first aid certificate plus transportation endorsement

- Emergency Medical Responder (EMR) — advanced first aid certificate

- Primary Care Paramedic (PCP) — advanced first aid certificate

- Advanced Care Paramedic (ACP) — advanced first aid certificate

- Critical Care Paramedic (CCP) — advanced first aid certificate

Employer obligations when employing first aid attendants with an EMA licence

Employers who deploy an EMA licence holder as a first aid attendant must ensure the licence holder has a working understanding of their responsibilities as an occupational first aid attendant. Employers may elect to do one of the following:

- Have first aid attendants with alternative qualification complete the Jurisprudence package prior to commencing work

- Provide on-the-job training that covers the topics outlined in the Jurisprudence package

- Have evidence that the EMA licence holder previously completed the jurisprudence package

Operational scope of EMALB licence holders

EMALB licences used in industry are subject to operational limitations (refer to the EMALB Position Statement on Operational vs. Legal Scope of Practice). Workplaces that employ EMAs as first aid attendants are expected to restrict their scope of practice to align with the competencies listed in CSA Z1210-17 for advanced first aid attendants, unless medical oversight by a physician registered with the College of Physicians and Surgeons of BC is in place, along with supplemental written procedures. Operational scope should clarify the following:

- First aid attendants may not administer prescription drugs or medications. First aid attendants may assist workers to self-administer medication for which they have a prescription if the patient provides a letter from their physician. First aid attendants may provide injured workers with non-prescription (over-the-counter) medications purchased by the employer for use at the worksite, if appropriate to do so.*

- First aid attendants must initiate immediate transfer to hospital for any injured worker who meets rapid transport criteria.*

* Refer to Advanced First Aid: A Reference and Training Manual for additional details on these requirements.

Suspending or revoking acceptance of alternative licences

WorkSafeBC may revoke the acceptance of an individual EMA licence holder as a first aid attendant without impacting the validity of the medical licence. Medical licences issued by EMALB may only be revoked or suspended by EMALB, and practice concerns that come to the attention of WorkSafeBC will be referred to the licensing board for investigation and appropriate remedy.

Refer to OHS Guideline G3.21(1) for additional details on suspending and revoking alternative licences.

G3.15(c) Proof of certification

Issued September 6, 2018; Revised consequential to November 1, 2024 Regulatory Amendment; Editorial Revision July 10, 2025

Regulatory excerpt

Section 3.15 of the OHS Regulation ("Regulation") states, in part:

The employer must ensure that a person who is designated as a first aid attendant

…

(c) has a first aid certificate in good standing at the required level issued by the Board or a person recognized by the Board, and

…

Purpose of guideline

This guideline is to outline the requirements for proof of certification at the workplace.

Requirement

Before assigning a first aid attendant to duty, employers must take reasonable measures to confirm that a worker has a valid first aid certificate (or other credential accepted under the provisions of section 3.15) that is in good standing and accepted by WorkSafeBC. First aid certificates and other credentials accepted by WorkSafeBC are listed on worksafebc.com: Certificates accepted in B.C.

The status of a licence issued by the Emergency Medical Assistants Licensing Board (EMALB) can be confirmed by either obtaining a licence status report from EMALB or reviewing the report posted on Licensing - Province of British Columbia.

Employers are expected to keep a copy of the attendant's first aid credential, and provide it to a WorkSafeBC officer upon request. It is recommended that employers track the expiration date of first aid credentials to ensure first aid attendants recertify when required. Where practical to do so, first aid credentials should be posted at the workplace for review by workers who may receive first aid.

First aid attendants must produce their original credential or a verifiable digital credential to their employer prior to their first shift as a first aid attendant. Attendants must also produce their credential to a WorkSafeBC officer upon request within a reasonable period.

Acceptable verifiable digital certificates permit the validity of the certificate to be confirmed through an online database maintained by the training agency. Employers should not accept digital photographs of certificates, where the authenticity of the certificate cannot be validated. Digital photographs may be accepted by WorkSafeBC officers as sufficient evidence of training, if the employer can confirm the certificate is valid.

First aid attendants are expected to notify their employer of any changes to the status of their licence or certification that could impact their ability to provide first aid services.

G3.16 First aid assessment

Issued March 30, 2004; Revised February 1, 2008; Editorial Revision September 6, 2018; Editorial revision October 30, 2018; Editorial Revision January 17, 2022; Revised consequential to November 1, 2024 Regulatory Amendment

Regulatory excerpt

Section 3.16 of the OHS Regulation ("Regulation") states:

(1) An employer must provide for each workplace

(a) at least the equipment, supplies, facilities, first aid attendants and services required by Schedule 3-A, and

(b) any additional equipment, supplies, facilities, first aid attendants and services that are necessary to ensure that workers who suffer an injury at work can be

(i) promptly provided first aid, and

(ii) promptly transported to medical treatment.

(2) For the purpose of complying with subsection (1)(b), the employer must prepare a written assessment that sets out at least the following information:

(a) the number of workers present;

(b) the locations of workers;

(c) the nature and extent of the risk and hazards in the workplace;

(d) the types of injuries likely to occur;

(e) any barriers to first aid being provided to an injured worker;

(f) the time that may be required to obtain transportation and to transport an injured worker to medical treatment and the methods of transportation available.

(3) The employer must review and update the assessment under subsection (2)

(a) within 12 months after the previous assessment or review, and

(b) whenever a significant change affecting the assessment occurs in the employer's operations.

(3.1) An assessment under subsection (2) must be prepared, reviewed and updated in consultation with the joint committee or the worker health and safety representative, as applicable.

(4) An employer must ensure that the equipment, supplies and facilities required by subsection (1) are

(a) suitable for their intended use,

(b) clean, dry and ready for use, and

(c) readily accessible

Purpose of guideline

This guideline explains the process for determining adequate first aid coverage. This guidance is designed to help employers establish which table in Schedule 3-A — Minimum Levels of First Aid sets out the minimum first aid services for their workplace, and provides clarity on additional factors that must be considered when determining first aid services.

For the purpose of this guideline, the term "first aid services" should be taken to include first aid equipment, supplies, facilities, and first aid attendants.

Employers' two-part duty

Section 3.16(1) sets out a two-part duty to determine the level of first aid supplies required at any given workplace. Section 3.16(1)(a) requires an employer to determine the minimum levels of first aid based on the employer's hazard rating, location and nature of workplace, and number of workers. Section 3.16(1)(b) requires employers to fully evaluate any circumstances unique to the workplace to determine any additional first aid equipment, supplies, facilities, attendants, and services necessary to ensure compliance with this regulation. Consideration of both parts must be done in consultation with the joint health and safety committee or worker health and safety representative, and documented in a written first aid assessment required by section 3.16(2).

Determining minimum first aid requirements — Section 3.16(1)(a)

Minimum first aid services are determined by assessing three factors:

- The number of workers present at the workplace

- Hazard rating

- The class of workplace (which includes consideration of both the remoteness and the accessibility of the workplace)

Step 1: Number of workers present at the workplace

When determining minimum first aid requirements, employers should calculate the maximum number of workers present at the workplace during a typical shift. All workers — including managers, supervisors, and administrative staff who are regularly present at the workplace — must be included in the worker count under this provision, regardless of whether they are normally exposed to the substantive hazards of the workplace.

Where the number of workers consistently varies between shifts, separate assessments may be conducted for each shift.

Section 13 of the Workers Compensation Act defines a "workplace" as "any place where a worker is or is likely to be engaged in any work and includes any vessel, vehicle or mobile equipment used by a worker in work."

Consider the following factors when determining if an area or building is part of a single workplace, or may be considered a separate workplace for the purpose of establishing first aid requirements:

Factors supporting a single workplace:

- Fixed work locations under the control of a single employer

- Multiple-employer workplaces where a prime contractor has been established

Factors supporting separate workplaces:

- Locations leased by one employer that are part of a larger property leased to others

- Locations controlled by one employer that are separated by locations controlled by other employers

- Locations of one employer that are more than 10 minutes apart from each other, or where physical barriers might prevent a first aid attendant from reaching an injured worker in less than 10 minutes (note that this factor should not be used to decrease minimum first aid requirements in high-risk remote industries, such as forestry, where workers work in small groups over large areas)

- A public roadway separates locations of one employer from each other in an urban area

- Locations under separate administrative structures, controlled by one employer

In any situation, the factors may point to different conclusions. It is then necessary to weigh those factors indicating one workplace against those indicating separate workplaces, considering the workplace structure and relative risk to workers. After considering all the factors, the option that provides an appropriate level of first aid service should be chosen.

Determining number of workers for workplaces that dispatch workers or that have transient workers

All workers who regularly attend a workplace must be included in the worker count for that workplace, even if they are on site only briefly.

When determining the minimum first aid requirements for a workplace, employers should count dispatched or transient workers as follows:

- Count as one worker each dispatched worker who stays within 10 minutes' surface travel time from the workplace for more than 50% of the shift.

- Count one-quarter of the number of workers who travel more than 10 minutes' surface travel time from the workplace more than 50% of the shift.

- Pro-rate the number of transient workers based on an estimation of the time they attend the workplace. For example, if a warehouse has eight loading bays that are serviced by a fleet of delivery trucks throughout the day, the employer may determine that it is reasonable to include an additional eight workers for the purpose of determining first aid requirements at the warehouse, if that is the maximum number of delivery drivers that are likely to be at the workplace at any given time.

Separate first aid assessment(s) are required for dispatched workers when they are not present at the central location.

It is recommended that personal first aid kits are present in all workplace vehicles that travel further than 10 minutes from the central workplace, unless a larger kit is required by Schedule 3-A, a first aid assessment, or the Motor Vehicle Act.

Other requirements for worker transportation under Part 17 of the Regulation must also be met.

Step 2: Determine your hazard rating