Contents

DIVISION 1 - GENERAL OPERATING REQUIREMENTS

G16.8(3) Rider restriction

DIVISION 2 - GENERAL MACHINE REQUIREMENTS

G16.24 Alternate means of escape - Purpose-built window breaking device

G16.30 Load handling attachments - Forklifts

G16.33 Protective structures for hydraulic excavators pioneering on steep side hills

G16.33-2 Protective structures - Acceptable alternate standards

G16.35 ROPS standards - Acceptable alternate standard

DIVISION 3 - ADDITIONAL REQUIREMENTS FOR SPECIFIC PRIME MOVERS

G16.40(8) All terrain vehicles - Modifications

G16.43(2)-1 Lift truck operator training

G16.43(2)-2 Lift truck operator training - Alternative standards

G16.43(5) Pedestrian and equipment traffic

RETIRED GUIDELINES

Guidelines retired consequential to September 1, 2021 Regulatory Amendments

Guidelines retired prior to September 1, 2021

Guidelines Part 16 - Division 1 - General Operating Requirements

G16.8(3) Rider restriction (formerly G16.31(4))

Issued August 1999; Revised consequential to September 1, 2021 Regulatory Amendment

Regulatory excerpt

Section 16.8(3) of the OHS Regulation ("Regulation") states:

(3) A person other than the operator may only ride on a ROPS-equipped prime mover for the purpose of training or maintenance and, for that purpose, the prime mover

(a) must not be operated in a rollover hazard area, and

(b) must not be engaged in an operation that could

(i) cause the mobile equipment to become unstable, or

(ii) cause the person to fall or be ejected, pinched or dragged.

Purpose of guideline

The purpose of this guideline is to hightlight section 16.8(3) of the Regulation that sets out certain requirements if a worker other than the operator must ride on ROPS equipped mobile equipment.

Rider requirements

Section 16.8(5) of the Regulation outlines the safety requirements for workers riding on prime movers that are not equipped with ROPS. These requirements include:

- A seat that meets the requirements of section 16.20

- A footboard or platform

- Hand-holds

- A safety belt, harness, guardrail, or other means of restraint

Although these requirements are not specifically mandated by section 16.8(3) for workers riding on ROPS-equipped prime movers, these or similar requirements should be met so that the rider can be transported safely.

Section 4.3(1) of the Regulation, which relates to safe machinery and equipment, still applies.

Guidelines Part 16 - Division 2 - General Machine Requirements

G16.24 Alternate means of escape - Purpose-built window breaking device (formerly G16.17)

Issued August 18, 2014; Revised consequential to September 1, 2021 Regulatory Amendment

Regulatory excerpt

Section 16.24 of the OHS Regulation ("Regulation") states:

(1) If mobile equipment manufactured after January 1, 2000 has a single cab entrance door, the mobile equipment must have an alternative means of escape that is clearly marked both inside and outside the cab and that

(a) is not located on the same surface as the cab entrance door,

(b) is usable regardless of the position of movable components or accessories of the machine,

(c) does not pose additional hazards to the operator,

(d) can be opened from both the inside and outside without the use of tools when the mobile equipment is in use,

(e) requires a force of not more than 135 N (30.3 lbf) to open, and

(f) provides a clear opening, the minimum dimensions of which comply with ISO Standard 2867-2011(R2016), Earth-moving machinery - Access systems.

(2) Mobile equipment manufactured before January 1, 2000 with a single cab entrance door must meet the requirements for an alternative means of escape required at the date of manufacture.

Purpose of guideline

This guideline describes when a purpose-built window breaking device may meet the requirements of section 16.24 of the Regulation.

Background

Section 16.24 of the Regulation requires an alternate means of escape for mobile equipment with a single cab entrance door. The intent of this requirement is to allow a secondary means of escape if the primary means is obstructed, e.g., due to fire, overturn, submersion, or other mishap.

In most circumstances an openable window can be built into a cab design, or a second door or hatch can be installed in the cab. This is what is anticipated by section 16.24(1) of the Regulation.

There may be circumstances where it is not practicable to install or retrofit the cab of mobile equipment with openable windows or to install a second door or hatch, such as the following:

- Cab structural strength would be significantly altered by installing an alternate means of escape

- A redesigned alternate means of escape would affect the machine capacity or range of motion

In these circumstances, it may be acceptable to install a purpose-built device to break a window in an emergency so that a person can escape from a cab. For example, this could be a commercially available device that permanently attaches directly to the window and can be used by the operator to break the glass by punching the device. Although the device does not open the window directly, it does open an egress point by breaking the window.

Use of a tool

The Regulation states that the alternate means of escape must be openable without the use of a tool. Therefore, it is not acceptable to rely on a hammer or other loose commercial glass breaking devices in the cab for the purpose of breaking a window. Even if the device is tethered to the window, it is still not an acceptable means because there is a significant chance of the device being removed or otherwise being unavailable in an emergency.

However, if a device can be permanently installed on a window so that it cannot be removed in any normal way (i.e., becomes integral with the glass), and can be readily used to break the window, then it would not be considered a tool and could be acceptable under the Regulation.

Mobile equipment manufactured after January 1, 2000

For mobile equipment manufactured after January 1, 2000, all the requirements of section 16.24(1) of the Regulation apply.

As an alternate means of escape, an openable hatch or window has some important advantages in terms of reliability. For example, a hatch can be tested and drills can be run regularly to check that the operator can open it in an emergency situation, whereas the purpose-built device cannot readily be tested to ensure the operator can use it to break a window in an emergency. Factors that may affect the utility and reliability of the purpose-built device include the following:

- The device will only be effective with certain types of window glass, e.g., tempered glass versus non-tempered or laminated glass. Not all window glass is tempered glass, and even when it is, it is not always labelled as such. An employer may need to contact the mobile equipment, device, and/or glass supplier to determine whether the glass is of a type that will be broken by the device.

- The device will only be effective for certain thicknesses of glass. An employer will need assurance that the device will work when required in an emergency.

- Tempered glass breaks into fragments rather than sharp shards. While the fragments do not represent the same high hazard as sharp angular shards, there is still a danger of fragments lodging in the skin or eye, and workers need to be made aware to take precautions when breaking the glass.

- When a tempered glass window breaks, it may stay relatively in place in the frame and will then need to be pushed in order to remove it from the frame.

- All equipment operators must be trained in how to properly use the device in an emergency, and refresher training may be required periodically.

- The device needs to be part of a regular inspection regime to ensure it remains in place and undamaged. There is no practical way to test the functioning of the device on a periodic basis. The device may have an expiry date and this will need to be part of the inspection.

- A window film (e.g., advertising, anti-vandalism) or double glazing may affect performance of the device.

A purpose-built device is acceptable if the following considerations are met:

- The requirements of Regulation sections 16.24(1)(a)–(f) are met.

- Manufacturer's instructions are followed (both the mobile equipment and the device manufacturer).

- It is not practicable to install an openable escape hatch, door, or window as the alternate means of escape.

- The window is of a type and condition that will break as necessary by use of the device according to the manufacturer's instructions. The window material and the thickness are important in this consideration.

- The window can be safely broken from the inside (by the equipment operator) and the outside (by rescuers).

- The window and attached device do not create an additional hazard. Tempered glass will break into fragments. Workers need to be made aware that the fragments could become embedded in the eye or skin and precautions need to be taken. If the window is of a type that will break into sharp shards that are likely to cause injury to a worker, then this method would not be acceptable.

- The installed device does not obscure the operator's view or otherwise hinder equipment operation.

- The device is installed in a location on the window so that it is likely to be readily accessible when necessary in case of mishap.

- The device is part of the pre-use inspection of the mobile equipment. The presence and condition of the device must be verified.

- Instructions on how to use the device are clearly visible inside and outside the window.

- The device is permanently affixed at the window.

- A qualified person has inspected the installed device and provided written confirmation to the employer that the device is installed in accordance with the considerations listed here. This information is provided to the joint health and safety committee or worker representative, as applicable, and is made available to a WorkSafeBC prevention officer upon request.

Mobile equipment manufactured prior to January 1, 2000

As per section 16.24(2) of the Regulation, mobile equipment manufactured prior to January 1, 2000 and having a single cab entrance door must be equipped with an alternate means of escape should the primary means be blocked.

The prescriptive requirements of sections 16.24(1)(a)-(f) do not apply to this mobile equipment. Employers should provide openable hatches or windows as an alternate means of escape wherever practicable — however, a purpose-built device such as described in this guideline is also acceptable as an alternate means of providing escape, provided that the manufacturer's instructions are followed.

G16.30 Load handling attachments – Forklifts (formerly G16.19)

Issued September 21, 2012; Editorial Revision consequential to February 1, 2013 Regulatory Amendment; Revised consequential to September 1, 2021 Regulatory Amendment

Regulatory excerpt

Section 16.30 of the OHS Regulation ("Regulation") states:

(1) Buckets, forks, booms, hoists and other load-handling attachments must be installed on mobile equipment as specified by the manufacturer of the mobile equipment unless otherwise certified by a professional engineer for use on the mobile equipment.

(2) The design of the attachments referred to in subsection (1) must provide for an evaluation of the stability of the mobile equipment, including the effect of load swing.

(3) The instructions of the manufacturer or professional engineer, as applicable, for the safe use of the mobile equipment with the attachment must be available to the operator.

Section 4.3(2) of the Regulation states:

(2) Unless otherwise specified by this Regulation, the installation, inspection, testing, repair and maintenance of a tool, machine or piece of equipment must be carried out

(a) in accordance with the manufacturer's instructions and any standard the tool, machine or piece of equipment is required to meet, or

(b) as specified by a professional engineer.

Section 4.8 of the Regulation states:

(1) Unless provided elsewhere in this Regulation, the rated capacity or rated load of a machine or piece of equipment is that specified by the manufacturer of the machine or piece of equipment based on its design.

(2) The rated capacity or rated load must be certified by a professional engineer if

(a) the manufacturer's specification or other acceptable warranty cannot be produced,

(b) the equipment or machine has been modified in a manner which will change its rated capacity or rated load,

(c) wear, corrosion, damage or signs of fatigue are found which may reduce the rated capacity or rated load,

(d) the equipment or machine is used in a manner or for a purpose other than that for which it was originally designed, if the use will change the safe working load, or

(e) in the opinion of the Board, the provision of such certification is deemed necessary.

Sections 16.43(1)(a) and (b) of the Regulation state:

(1) The design, fabrication, use, inspection, maintenance and repair of a lift truck must meet

(a) CAN/CSA Standard B335-15-Safety standard for lift trucks, or

(b) as applicable,

(i) ANSI/ITSDF B56.la-2018, Safety Standard for Low Lift and High Lift Trucks,

(ii) ANSI/ITSDF B56.6-2016, Safety Standard for Rough Terrain Forklift Trucks, or

(iii) ISO 10896 Rough-Terrain Trucks - Safety Requirements and Verification: Part 1 (2012): Variable-Reach Trucks; Part 2 (2016): Slewing Trucks; Part 4 (2015): Additional Requirements for Variable-Reach Trucks Handling Freely Suspended Loads

or the earlier version of the applicable standard that applied on the date of manufacture of the lift truck.

Purpose of guideline

This guideline provides information regarding the Regulation requirements pertaining to installation, written instructions regarding safe use and stability, and determination of rated capacity when a forklift (also known as a lift truck) is fitted with a load handling attachment.

Installation requirements

There are a number of load handling attachments available for low lift, high lift, and rough terrain forklifts; including fork extensions, telescoping booms, and attachable hoisting devices (hooks, clamps, side shifters, etc.). These load handling attachments are available both from the forklift manufacturer and from third-party manufacturers. Sections 4.3(2) and 16.30(1) of the Regulation require that installation of these attachments be carried out by either of the following:

- In accordance with instructions from the manufacturers of both the load handling attachment and the forklift, and the requirements of the relevant forklift standard

- By a professional engineer

Safe use and stability instructions

The potential for instability of the forklift when a load handling attachment is installed and when a load is applied to the attachment is a key hazard to be considered in the development of written safe use instructions required under sections 16.30(2) and (3) of the Regulation.

Instructions for safe use of the forklift with the load handling attachment should address the following factors:

- Changes to the stability of the forklift caused by the following:

- Any extension of the load past the normal point for the load rating of the forklift

- The swing of any suspended load

- Any altered load capacity caused by the use of the load handling attachment

- Any altered handling characteristics of the forklift or forklift capabilities, such as maximum fork elevation for a specific forklift

- Whether the specifications and instructions of either the forklift manufacturer or the load attachment manufacturer are affected when the forklift and attachment are combined

- The relevant specifications and instructions from the appropriate standard (refer to sections 16.43(1)(b); these standards include requirements for the use of load handling attachments

Nameplates

If a forklift is equipped with a load handling attachment, clause 4.2.3 of ANSI/ITSDF B56.1-2009 requires the forklift be marked to identify the attachment, show the weight of the combination of the truck and attachment, and show the capacity of the truck with the attachment at maximum elevation with the load laterally centred.

Rated capacity

Load handling attachments that do any of the following:

- Allow the load to swing

- Significantly elevate the normal centre of gravity of the load

- Reposition the allowable centre of gravity of the load past the normal load rating position (as specified by the forklift manufacturer)

The forklift manufacturer may have anticipated the effects of the use of load handling attachments and specified the rated capacity for this use. Where the forklift manufacturer has not provided for this use in the design and specifications of the equipment and has not specified the appropriate rated capacity, or if the manufacturer's (or authorized agent's) specifications are not available, sections 4.8(2)(a) and (b) of the Regulation require that the modified rated capacity or rated load be certified by a professional engineer.

G16.33 Protective structures for hydraulic excavators pioneering on steep side hills (formerly G16.21)

Issued August 1999; Editorial Revision April 2005; Revised consequential to September 1, 2021 Regulatory Amendment

Regulatory excerpt

Sections 16.33(1) and (2) of the OHS Regulation ("Regulation") state:

(1) In this section and section 16.38, "tipover", in respect of mobile equipment, means a roll about the longitudinal axis of up to 90°, or a rear or frontal pitchover about the transverse axis of up to 90°, which roll or pitchover results in the contact of the cab with a surface.

(2) Operators of mobile equipment, and any other riders of mobile equipment authorized by section 16.8, must be protected against any reasonably foreseeable hazards from falling, flying or intruding objects or materials, or tipovers, by means of cabs, windows, screens, grills, shields, deflectors, guards or structures on the mobile equipment that

(a) are designed and installed to provide an adequate view for the operator to safely use the mobile equipment, and

(b) meet the requirements of

(i) at least one of the following standards, if the mobile equipment is in the scope of the standard:

(B) Society of Automotive Engineers (SAE) Recommended Practice J1356 MAR2013, Performance Criteria for Falling Object Guards for Excavators;

(C) SAE J2267 APR2007 Minimum Performance Criteria for Operator Front Protective Structures (OFPS) for Certain Equipment;

(D) ANSI/UL 752, Standard for Bullet-Resisting Equipment, 11th edition (with revisions up to and including December 11, 2015);

(E) WorkSafeBC G601 Standard - Heavy Duty Backstops for Logs and Rocks, set out in Schedule 16-A of this Part;

(F) WorkSafeBC G603 Standard - Heavy Duty Guards for Windows, set out in Schedule 16-B of this Part;

(G) WorkSafeBC G604 Standard - Light Duty Guards for Windows, set out in Schedule 16-C of this Part, or

(ii) an earlier version of at least one of the standards set out in subparagraph (i)(A) to (D), if the earlier version applied to the cabs, windows, screens, grills, shields, deflectors, guards or structures on the mobile equipment on the date of manufacture of the mobile equipment.

Purpose of guideline

This guideline provides alternate standards to those listed in section 16.33(2)(b) of the Regulation when dealing with protective structures for hydraulic excavators pioneering on steep side hills.

Alternative standards

The standards referenced in section 16.33 deal with the minimum operator protection expected on a hydraulic excavator exposed to the hazard of intruding or flying objects, such as loose debris, snags, tree trunks, or limbs, which are conditions normally encountered in pioneering steep side hill logging grades and right-of-way construction.

Section 4.4(2)(b) of the Regulation permits the reliance on other practices, procedures, or rules which are acceptable to WorkSafeBC. The following applicable alternates to the standards listed in the Regulation are considered acceptable:

- WCB Standard: G602 Log Loader and Log Yarder Raised Cabs - cab structure designed to resist a force of at least 11,500 pounds (simulating a 2000 pound blunt log impacting the cab at approximately 4 miles per hour), and an alternative exit meeting the requirements of section 16.17 of the Regulation.

- WCB Standard: G608 Mobile Equipment Roof Structures - Heavy Duty (designed to absorb 8500 foot - pounds of energy). (SAE J1043 - Minimum Performance Criteria for Falling Object Protective Structures for Industrial Equipment or equivalent standard is an accepted option under add either WCB or WorkSafeBC G608.)

- An adequate substitute for WCB Standard G603 window guards is polycarbonate (sold under the trade names of Lexan or Tuffac) where it is at least 1/2 inch thick and adequately supported from behind along the perimeter with at least a one inch overlap and by members in one direction not more than 10 inches apart.

Where boom clearance does not permit a side window guard meeting WCB Standard G603, a window guard meeting WCB Standard G604, Standard for Light-Duty Screen Guards for Off-Highway Equipment may be used. Section 16.33(2)(b)(i)(A) of the Regulation requires each polycarbonate window on mobile equipment manufactured after February 1, 2002, or otherwise installed on mobile equipment after that date, to be marked to show the thickness and grade of the material.

Do not drill holes in polycarbonate windows to mount the window on the machine, or for the installation of accessories such as windshield wipers. Email WorkSafeBC's Prevention Practice, Quality, and Engineering department for further assistance on window guards made using polycarbonate.

G16.33-2 Protective structures - Acceptable alternate standards (formerly G16.21(2)-2)

Issued October 26, 2011; Revised consequential to September 1, 2021 Regulatory Amendment

Regulatory excerpt

Section 16.33(2) of the OHS Regulation ("Regulation") states:

(2) Operators of mobile equipment, and any other riders of mobile equipment authorized by section 16.8, must be protected against any reasonably foreseeable hazards from falling, flying or intruding objects or materials, or tipovers, by means of cabs, windows, screens, grills, shields, deflectors, guards or structures on the mobile equipment that

(a) are designed and installed to provide an adequate view for the operator to safely use the mobile equipment, and

(b) meet the requirements of

(i) at least one of the following standards, if the mobile equipment is in the scope of the standard:

(B) Society of Automotive Engineers (SAE) Recommended Practice J1356 MAR2013, Performance Criteria for Falling Object Guards for Excavators;

(C) SAE J2267 APR2007 Minimum Performance Criteria for Operator Front Protective Structures (OFPS) for Certain Equipment;

(D) ANSI/UL 752, Standard for Bullet-Resisting Equipment, 11th edition (with revisions up to and including December 11, 2015);

(E) WorkSafeBC G601 Standard - Heavy Duty Backstops for Logs and Rocks, set out in Schedule 16-A of this Part;

(F) WorkSafeBC G603 Standard - Heavy Duty Guards for Windows, set out in Schedule 16-B of this Part;

(G) WorkSafeBC G604 Standard - Light Duty Guards for Windows, set out in Schedule 16-C of this Part, or

(ii) an earlier version of at least one of the standards set out in subparagraph (i)(A) to (D), if the earlier version applied to the cabs, windows, screens, grills, shields, deflectors, guards or structures on the mobile equipment on the date of manufacture of the mobile equipment.

Purpose of guideline

Section 4.4(2)(b) of the Regulation permits the reliance on other practices, procedures, or rules which are acceptable to WorkSafeBC. This guideline describes acceptable alternate WCB G600 series standards for protective structures on mobile equipment to standards referenced in section 16.33 of the Regulation.

Acceptable alternate standards

The following standards are acceptable alternate standards for the standards referenced in section 16.33 of the Regulation.

- WCB Standard G602 - Log Loader and Log Yarder Raised Cabs

- WCB Standard G605 - Mobile Equipment Half-Doors

- WCB Standard G606 - Boom Boat Cab Protection

- WCB Standard G607 - Medium Duty Screen Guards - Front End Log Loader

- WCB Standard G608 - Mobile Equipment Roof Structures - Heavy Duty

- WCB Standard G609 - Mobile Equipment Roof Structures - Light Duty

The WCB Standards G600 series listed above are alternate standards to the following standards referenced in section 16.33 of the Regulation.

1. WCB Standard G602 - Log Loader and Log Yarder Raised Cabs. Cab structure designed to resist a force of at least 11,500 pounds (simulating a 2000 pound blunt log impacting the cab at approximately 4 miles per hour), and an alternate exit meeting the requirements of section 16.24 of the Regulation.

G602 is an alternate standard to the following standards listed in section 16.33 of the Regulation. Note: CSA Standard B352.0-16, Rollover protective structures (ROPS), falling object protective structures (FOPS), operator protective structures (OPS), and tip-over protective structures (TOPS) for mobile machinery - General Canadian requirements references the standards below:

A. CAN/CSA-M12117-05(R2015) Earth-moving machinery - Tip-over protection structure (TIP) for compact excavators - Laboratory test and performance requirements

B. Can/CSA M3471-05 (R2015) Earth-moving machinery - Roll-over protective structures - Laboratory tests and performance requirements

C. CAN/CSA-M8082-1-09 Self-propelled machinery for forestry - Laboratory tests and performance requirements for roll-over protective structures - Part 1 General Machines

D. CAN/CSA-M8082-2-11 Self-propelled machinery for forestry - Laboratory tests and performance requirements for roll-over protective structures - Part 2 Machines having rotating platform with a cab and boom on the platform

2. WCB G605 Standard - Mobile Equipment Half-Doors; G605 covers half-doors on skidders. No new skidders are produced with half-doors. There are no identified accepted alternate standards for half-doors; however ISO 8084 covers full doors.

WCB Standard G605 is the alternate of ISO 8084:2003 Machinery for forestry - Operator protective structures - Laboratory tests a performance requirements. ISO 8084:2003 is a referenced standard in CSA Standard B352.0-16.

3. WCB G606 Standard - Boom Boat Cab Protection. No new boom boats are being produced and there is no identified acceptable alternate standard. G606 is referenced in section 26.86 of the Regulation and is included here for information purposes.

4. WCB G607 Standard - Medium Duty Screen Guards - Front End Log Loader; G607 covers log loaders operating in less hazardous situations than those anticipated by G603. Where a G607 guard is required a G603 guard can be substituted.

5. WCB G608 Standard - Mobile Equipment Roof Structures - Heavy Duty; G608 is an alternate to ISO 8083 (11,600 J level), ISO 3449 Level II, ISO 10262 Level II FOPS as a method of compliance. All require a 500 lb. object to be dropped with 8,500 ft-lbs energy. These standards are referenced in CSA Standard B352.0-16.

A. ISO 3449:2005 Earth-moving machinery - Falling-object protective structures - Laboratory tests and performance requirements

B. ISO 8083:2006 Machinery for forestry - Falling-object protective structures (FOPS) - Laboratory tests and performance requirements

C. ISO 10262:1998 Earth-moving machinery - Hydraulic excavators - Laboratory tests and performance requirements for operator protective guards

6. WCB G609 Standard - Mobile Equipment Roof Structures -- Light Duty; G609 is an alternate to ISO 3449 Level I and ISO 10262 Level I FOPS as a method of compliance. These standards are referenced in CSA Standard B352.0-16.

A. ISO 3449:2005 Earth-moving machinery - Falling-object protective structures - Laboratory tests and performance requirements

B. ISO 10262:1998 Earth-moving machinery - Hydraulic excavators - Laboratory tests and performance requirements for operator protective guards

G16.35 ROPS standards - Acceptable alternate standard (formerly G16.23)

Issued January 1, 2005; Revised March 9, 2012; Revised consequential to September 1, 2021 Regulatory Amendment

Regulatory excerpt

Section 16.35 of the OHS Regulation ("Regulation") states:

(1) A ROPS installed on mobile equipment other than

(a) an excavator between 6 tonnes (13 250 lbs) and 50 tonnes (110 231 lbs),

(b) powered ride-on turf care equipment heavier than 400 kg (882 lbs), or

(c) a UTV must meet the requirements of the CSA Standard B352.0-16 - Roll-over protective structures (ROPS), falling object protective structures (FOPS), operator protective structures (OPS), and tip-over protective structures (TOPS) for mobile machinery - General Canadian requirements or the earlier version of the standard that applied on the date of manufacture of the mobile equipment.

(2) A ROPS installed on an excavator between 6 tonnes (13 250 lbs) and 50 tonnes (110 231 lbs) must meet the requirements of the ISO 12117-2: 2008 Earth-moving machinery - Laboratory tests and performance requirements for protective structures of excavators - Part 2: Roll-over protective structures (ROPS) for excavators of over 6 t.

(3) A ROPS installed on powered ride-on turf care equipment heavier than 400 kg (882 lbs) must meet the requirements of ISO 21299:2009 Powered ride-on turf care equipment- Roll-over protective structures (ROPS) - Test procedures and acceptance criteria.

(4) A ROPS installed on a UTV must meet the requirements of section 16.41(1).

Section 4.4(2) of the Regulation states, in part:

(2) When this Regulation requires a person to comply with

(a) a publication, code or standard of the Board or another agency, the person may, as an alternative, comply with another publication, code or standard acceptable to the Board …

Purpose of guideline

The purpose of this guideline is to cite an alternative standard acceptable to WorkSafeBC for section 16.35 of the Regulation.

Acceptable alternate standards for agricultural tractors

Section 16.35 of the Regulation requires rollover protective structures (“ROPS”) to meet one of the applicable standards listed for agricultural, construction, earth-moving, forestry, industrial, and mining machines. Section 4.4(2)(a) of the Regulation permits WorkSafeBC to accept alternative standards.

WCB Standard G602 - Log Loader and Log Yarder Raised Cabs is an alternate standard to CAN/CSA-M12117-05(R2015) Earth-moving machinery - Tip-over protection structure (TIP) for compact excavators - Laboratory test and performance requirements and the CAN/CSA M3471-05 (R2015) Earth-moving machinery - Roll-over protective structures - Laboratory tests and performance requirements, which are included in the CSA Standard B352.0-16 - Roll-over protective structures (ROPS), falling object protective structures (FOPS), operator protective structures (OPS), and tip-over protective structures (TOPS) for mobile machinery - General Canadian requirements.

Guidelines Part 16 - Division 3 - Additional Requirements for Specific Prime Movers

G16.40(8) All terrain vehicles - Modifications (formerly G16.50)

Issued August 1999; Editorial Revision January 31, 2013; Revised consequential to September 1, 2021 Regulatory Amendment

Regulatory excerpt

Section 16.40(8) of the OHS Regulation ("Regulation") states:

(8) A modification or attachment to an ATV that may affect its stability must be certified by the manufacturer or a professional engineer.

Purpose of guideline

The purpose of this guideline is to explain the intent of section 16.40(8) of the Regulation and to give examples of modifications to all-terrain vehicles (ATVs) that require certification by the manufacturer or a professional engineer.

Modifications to ATVs

Some modifications affecting structural integrity that fall within the intent of this section include the following:

- Modifications to the frame, suspension, or steering

- Critical components replaced with lower quality items

- Poor repair practices, for example, bad welding or welding non-weldable parts

- Increasing horsepower or torque

Some modifications affecting stability that fall within the intent of this section include the following:

- Changing the centre of gravity

- Changing the suspension

- Changing the load distribution and size

- Changing the wheelbase

- Changing the horsepower or gearing

- Installing tanks for carrying liquids without adequate internal baffles in the tanks

G16.43(2)-1 Lift truck operator training (formerly G16.7(j)-1)

Issued April 25, 2002; Editorial Revision June 2005; Editorial Revision August 13, 2008; Editorial Revision November 21, 2017; Revised consequential to September 1, 2021 Regulatory Amendment; Editorial Revision consequential to August 22, 2022 Regulatory Amendment

Regulatory excerpt

Sections 16.43(1) and (2) of the OHS Regulation ("Regulation")

state:

(1) The design, fabrication, use, inspection, maintenance and repair of a lift truck must meet

(a) CAN/CSA Standard B335-15-Safety standard for lift trucks, or

(b) as applicable,

(i) ANSI/ITSDF B56.1a-2018, Safety Standard for Low Lift and High Lift Trucks,

(ii) ANSI/ITSDF B56.6-2016, Safety Standard for Rough Terrain Forklift Trucks, or

(iii) ISO 10896 Rough-Terrain Trucks - Safety Requirements and Verification: Part 1 (2012): Variable-Reach Trucks; Part 2 (2016): Slewing Trucks; Part 4 (2015): Additional Requirements for Variable-Reach Trucks Handling Freely Suspended Loads

or the earlier version of the applicable standard that applied on the date of manufacture of the lift truck.

(2) Operator training for lift trucks must meet the requirements of Clause 6 of the standard referred to in subsection (1)(a).

Purpose of guideline

The purpose of this guideline is to explain the training requirements for lift truck operators.

Background

Section 16.43(2) requires lift truck operators be trained in accordance with CSA Standard B335-15 Safety standards for lift trucks, Industrial Lift Truck Operator Training. (Note: For a copy of CSA Standard B335-15, visit community.csagroup.org. Access is free but registration is required.)

For the purposes of this guideline and application of section 16.43(2) of the Regulation, WorkSafeBC considers a trainee to be a person who is taking training to become a lift truck operator. A lift truck operator is not considered a "trainee" when taking refresher or upgrading courses and related training.

A trainee must satisfy medical and fitness criteria before starting training. These requirements are outlined in the CSA standard and are summarized later in this guideline.

Completion of training and testing

The employer is responsible for ensuring a trainee completes training and testing that meets the performance criteria specified in section 16.43(2) before the person is assigned tasks as a lift truck operator. If an employee claims to have past training and/or experience as a lift truck operator, the employer is responsible for checking references and assessing the new employee's ability to meet the performance criteria specified in section 16.43(2) before assigning the person to be a lift truck operator.

Lift truck operators do not need a certificate to confirm satisfactory performance and completion of the training mandated by section 16.43(2). The employer has several options for achieving compliance. Completing an external training course that effectively covers the specified standard, including the testing requirements, is one option to satisfy the Regulation. Another option is for the employer to provide in-house training and testing, to confirm the operator's knowledge and abilities meet the specified standard. Regardless, the employer still has an obligation to provide sufficient supervision and control in the workplace to ensure lift truck operators meet the standard on an ongoing basis.

In CSA standard B335-15, section 6.21.1 "Retraining" stipulates a lift truck operator must take a refresher course within a period "not exceeding three years" or if there is an accident or incident attributable to operator error. The employer is responsible for assessing each lift truck operator's performance on an ongoing basis. Training courses shall be tailored to the individual's needs as demonstrated by an evaluation, and assessment refresher courses and retraining only need to cover the aspects of lift truck operation that the operator is considered to be deficient in relative to the performance criteria specified in section 16.43(2). If three years after the last refresher or upgrading course an operator is not considered by the employer to have any deficiencies relative to the performance criteria, the refresher course could simply be a general job safety review with the operator. Training is also required any time new equipment is to be used, performance issues become evident, or there are significant changes in the operator's job.

The employer should keep sufficient records of lift truck operator training, testing, and assessment to document compliance with 16.43(2).

Driver's licence requirements

A lift truck operator using a lift truck exclusively on the employer's private property does not need to have a valid driver's licence. However, if the lift truck is operated on a public roadway, the provisions of the Motor Vehicle Act apply, and the operator needs a valid driver's licence of the appropriate class, including any required endorsements such as for air brakes, if applicable.

Propane handler's certificate

A lift truck operator (or any other person) required to dispense (transfer) propane from one container to another during refuelling of a lift truck must have a "propane handler's certificate." CSA Standard B149.2 Propane Storage and Handling Code is adopted under the Gas Safety Regulation as a requirement in B.C. Clause 4.2.1 of the CSA standard states: "Propane shall only be transferred from one container to another by a person who is the holder of a certificate recognized by the authority having jurisdiction." The authority having jurisdiction in British Columbia is the Technical Safety BC Safety Manager. The Safety Manager recognizes programs that are qualified to issue certificates. Propane suppliers are usually connected to a propane industry program recognized to provide training and certification acceptable to the Safety Manager. A source for information on obtaining a certificate is the Propane Training Institute at 1-877-784-4636, or online at http://www.propane.ca. Workers dispensing propane should have their certificate available at the location where the activity is being done. This is normally achieved by having the certificate posted at or near the dispensing station. If there is a concern regarding the validity of a certificate, consult the local Gas Safety inspection office.

If the lift truck refuelling process only involves changing propane cylinders, a propane handler's certificate is not required, but the operator or other person doing the task should have appropriate training to perform this function. Also, if a lift truck operator is required to refuel the lift truck with a product other than propane, or to change batteries or connect to a battery charger, the operator's training should cover these tasks.

Detailed training program requirements

Medical and Physical Fitness

A trainee must meet the medical and physical fitness requirement specified in CSA Standard B335-15 before starting training. This requirement does not apply to existing lift truck operators who are successfully doing this work without difficulty and are taking refresher or upgrading courses. If, however, a lift truck operator appears to have difficulty operating the lift truck in a satisfactory manner, the employer has the right and obligation to investigate. This investigation may include requiring evidence of compliance with the medical and physical fitness criteria.

The medical and physical fitness criteria is specified in the CSA standard and should include the following:

- Vision of not less than 20/40 in the better eye and good judgment of space including height and distance. If corrective eyewear is required to comply with the above, the operator must use it while operating a lift truck.

- Ability to distinguish colour, if colour differentiation is required on the assigned job.

- Ability to hear warning signals. If the operator requires a hearing aid to comply with the above, it must be worn while operating a lift truck.

- Full movement of trunk, neck, and upper and lower limbs, and the strength, endurance, agility, and coordination to meet the demands of the job.

Compliance with the above medical and physical fitness requirements may be determined by a doctor, a nurse, or another responsible party who by training has the ability to make such a determination. Trainees or operators cannot make their own determination on the above criteria.

Overview of Training Program Content

A training program will include classroom theory elements, practical (hands-on) training, and testing. The following summarizes the CSA Standard B335-15 criteria.

Classroom theory portion

Background

- Relevant legislation and fundamental safety guidelines, rules, and safety codes applicable to the job

- Basic principles of lift truck operation, including a focus on lift types, reach, and stability

- Main components of lift trucks

- Manufacturer's operating manual for the equipment to be used

Basic principles of operation

- Start-of-shift checks

- Shutdown and parking procedures

- Safe practices for starting, stopping, and turning

- Lift truck stability factors including items such as speed, cornering, load security, centre of gravity, and grade

- Capacity plate and its location

- Safe procedures for operating on ramps and grades

- Forward and reverse driving

- Correct use of lift trucks

- Driving hazards such as slippery surfaces, restricted visibility, and exhaust emissions

- Lift truck safety including generic safety procedures in accordance with the manufacturer's operating manual

- Lifting, lowering, or supporting people

Load handling

- General safe methods and procedures for pickup, conveyance, and depositing

- Selection of loads and assessing mass distribution for capacity, security, and integrity

- Preparation for load pickup and placement

- Assessing the safety of load-supporting structures

- Loading trucks, trailers, and railway cars

- Inclines or ramps

- Safety equipment and devices

- Hazards in the operating environment

Refuelling and/or recharging

- Refuelling a permanently mounted propane fuel tank

- Changing a removable propane cylinder

- Propane cylinder inspection

- Charging batteries on electric trucks

- Refuelling with other fuels

- Reporting unsafe operating conditions of vehicles

Operational (hands-on) training

The classroom theory elements covered are to be followed with practical demonstration and supervised practice.

Testing

- A trainee or operator may demonstrate proficiency in classroom theory areas by way of a written or oral test.

- A trainee or operator must demonstrate proficiency through an operational test showing skill and understanding of the safe operation of the lift truck(s).

G16.43(2)-2 Lift truck operator training - Alternative standards (formerly G16.7(j)-2)

Issued November 21, 2006; Revised consequential to September 1, 2021 Regulatory Amendment; Editorial Revision consequential to August 22, 2022 Regulatory Amendment

Regulatory excerpt

Sections 16.43(1) and (2) of the OHS Regulation ("Regulation")

state:

(1) The design, fabrication, use, inspection, maintenance and repair of a lift truck must meet

(a) CAN/CSA Standard B335-15-Safety standard for lift trucks, or

(b) as applicable,

(i) ANSI/ITSDF B56.1a-2018, Safety Standard for Low Lift and High Lift Trucks,

(ii) ANSI/ITSDF B56.6-2016, Safety Standard for Rough Terrain Forklift Trucks, or

(iii) ISO 10896 Rough-Terrain Trucks - Safety Requirements and Verification: Part 1 (2012): Variable-Reach Trucks; Part 2 (2016): Slewing Trucks; Part 4 (2015): Additional Requirements for Variable-Reach Trucks Handling Freely Suspended Loads

or the earlier version of the applicable standard that applied on the date of manufacture of the lift truck.

(2) Operator training for lift trucks must meet the requirements of Clause 6 of the standard referred to in subsection (1)(a).

Section 4.4(2)(a) of the Regulation states:

(2) When this Regulation requires a person to comply with

(a) a publication, code or standard of the Board or another agency, the person may, as an alternative, comply with another publication, code or standard acceptable to the Board…

Purpose of guideline

Section 16.43(2) of the Regulation requires that lift truck operators be trained in accordance with CAN/CSA Standard B335-15 - Safety standard for lift trucks

The purpose of this guideline is to specify an alternative to the CAN/CSA standard that is acceptable to WorkSafeBC, and to summarize the applicable requirements of the alternative standard.

ASME B56.1-2004 Safety Standard for Low Lift and High Lift Trucks

WorkSafeBC accepts the training part of this standard (but not the retraining or upgrading portions) - set out in paragraph 4.19 and the references therein - as an alternative to the training portions of the Standard.

For retraining and upgrading, the provisions in the above noted CSA Standards are to be used.

Note: In 2005 the copyright of this ASME standard was obtained by ITSDF (Industrial Truck Standards Development Foundation) in Washington, DC. The standard number was changed to ANSI/ITSDF B56.1-2005 (Reaffirmation of ASME B56.1-2004). This standard can be downloaded from the ITSDF website at: www.itsdf.org/forms/regusers/standards/2154_ITSDF-B56-1-2020-rev-12-12-22.pdf.

G16.43(5) Pedestrian and equipment traffic (formerly G16.43(3))

Issued August 1999; Revised August 1, 2013; Revised consequential to September 1, 2021 Regulatory Amendment

Regulatory excerpt

Section 16.43(5) of the OHS Regulation ("Regulation") states:

(5) In areas where lift truck use is separated from pedestrian traffic, a lift truck may travel forward with an elevated load if such operation will improve the operator's view of the path of travel, provided that operating conditions are maintained to ensure vehicle stability and the specifications of the mobile equipment manufacturer are not compromised.

Purpose of guideline

The purpose of this guideline is to provide information on low lift and high lift truck stability.

Lift truck stability

A lift truck works on the principle of the truck and its load balanced over a fulcrum, where the weight of the lift truck counterbalances the load on its forks (similar to the seesaw principle). The fulcrum, located in the centreline of the front axle of the truck, is the pivot point of the seesaw. See Figure 1.

When a lift truck's load exceeds its capacity rating (weight and/or load centre), unstable conditions are introduced that may cause the truck to tip over.

The capacity rating of a lift truck is identified on its data plate (affixed to the truck by the manufacturer) and displays the maximum load (expressed in pounds or kilograms) it can safely raise, lower, and move. The capacity rating consists of two components: weight and load centre. The weight is the weight of the load. The load centre is the horizontal distance between the face of the forks and the centre of gravity (CG) of the load (expressed in inches or millimetres), and the vertical distance of the travelling surface to the load centre. The CG is the point on an object where its weight is evenly dispersed and all its parts are in balance.

A front end attachment (e.g., fork extension, paper roll clamp) on a lift truck has its own rated capacity causing the truck's load capacity rating to change.

As a load centre distance increases the "load moment" increases. The load moment, or moment, is the product of the load's weight multiplied by the distance of the CG of the load to the fulcrum (pivot point). It is the moment that determines how much overturning force is being applied to the lift truck. For example, if a forklift's stated capacity rating is 3,000 pounds at a 24 inch load centre, the load moment cannot safely exceed 72,000 inch-pounds (24 inches x 3,000 lb = 72,000 inch-pounds). If the load centre distance for the actual load is greater than 24 inches, the only way to keep the load moment from exceeding 72,000 inch-pounds, which could result in the forklift tipping over laterally, is to reduce the load.

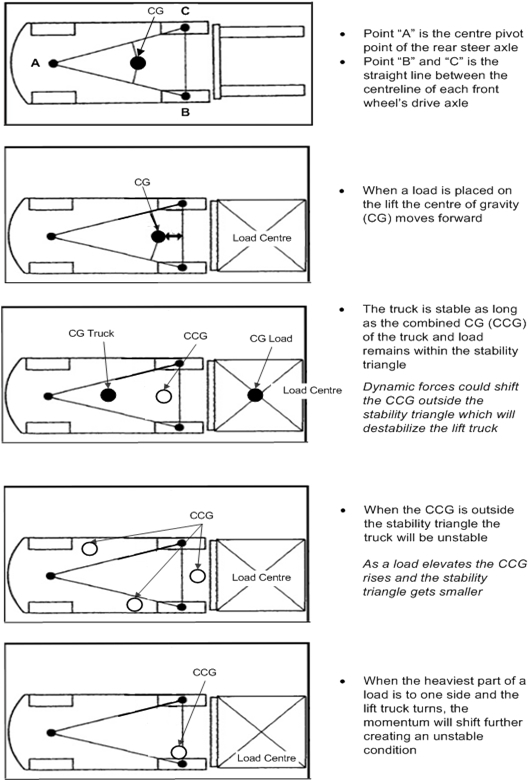

Stability triangle

A lift truck's steer axle is attached to the truck by a pivot pin in its rear axle's centre. When this point is connected to the centre of the two front wheels with imaginary lines it forms a triangle called the stability triangle. A lift truck and load each has its own CG. When a load is placed on a lift truck, the CG of the truck shifts, and a combined centre of gravity (CCG) is created. If the CCG is located outside the stability triangle, unstable conditions are introduced causing the truck to tip over either laterally on its side or tip longitudinally forward. Tip direction is determined by where the CCG is outside the stability triangle. See Figure 2.

Measures to ensure stability

The following measures are not an exhaustive list and do not replace lift truck safety standards:

- Ensure the lift truck is in good operating condition (e.g., the tires are inflated in accordance with the truck's manufacturer standards, brakes are in optimal working condition).

- Ensure the load is positioned against the mast, centred across the forks, and its weight evenly distributed.

- Avoid tilting forks forward unless picking up or setting down a load.

- Exercise caution when handling loads that are close to the truck's stated capacity rating.

- When elevating a load, reduce the load capacity, and carry it at its lowest possible position.

- Maintain a clear path of travel and be aware of blind spots.

- Travel at a slow speed, and exercise extra caution when turning.

- Keep loads elevated only for as long as required to clear the obstruction. The higher the load is elevated, the less stable the lift truck becomes.

- Be aware of the impact of dynamic forces (e.g., braking suddenly, accelerating rapidly, turning sharply, operating on uneven surfaces) as the load moment created by these motions may cause the lift truck to tip over.

Stability references

Additional stability references can be found under the following standards:

- CAN/CSA-B335-04 Safety standard for lift trucks

- ANSI/ITSDF B56.1 Safety Standard for Low Lift and High Lift Trucks

Guidelines Part 16 - Retired Guidelines

The following guidelines were retired consequential to the September 1, 2021 Regulatory Amendments.

G16.3 (and 4.3(3)) Tag out procedure for identifying unsafe mobile equipment

Issued August 1, 1999; Editorial Revision April 2005; Retired consequential to September 1, 2021 Regulatory Amendment

The guideline is being retired consequential to the September 1, 2021 Regulatory Amendment as this procedure is covered under section 4.3 of the OHS Regulation.

G16.3 (and 4.3(4)) Fuel tank filler and vent outlet locations

Issued August 1999; Editorial Revision April 12, 2005; Editorial Revision January 1, 2007; Retired consequential to September 1, 2021 Regulatory Amendment

This guideline is being retired as the amended OHS Regulation now covers this requirement.

G16.4(1)(c) Operating equipment with air brakes

Issued August 16, 2000; Retired consequential to September 1, 2021 Regulatory Amendment

This guideline is being retired consequential to the September 1, 2021 Regulatory Amendment as the amended section 16.14(1) of the OHS Regulation no longer allows alternatives to an air brake certificate or driver's licence with industrial air brake endorsement.

G16.13 Braking requirements - Mobile equipment - Alternate standard

Issued June 14, 2013; Retired consequential to September 1, 2021 Regulatory Amendment

This guideline is being retired consequential to the September 1, 2021 Regulatory Amendment as the acceptable standards are now listed in the revised OHS Regulation.

G16.13(3) Braking requirements - Mobile equipment

Issued April 1, 2013; Retired consequential to September 1, 2021 Regulatory Amendment

This guideline is being retired consequential to the September 1, 2021 Regulatory Amendment as the acceptable standards are now listed in the revised OHS Regulation.

G16.18 Acceptable standards for operating controls

Issued August 1999; Revised November 18, 2009; Retired consequential to September 1, 2021 Regulatory Amendment

This guideline is being retired consequential to the September 1, 2021 Regulatory Amendment as the requirements for operating controls are covered by section 12.11(2) of the OHS Regulation.

G16.21(2)-1 Operator protective structure standards for agricultural tractors

Issued January 1, 2005; Retired consequential to September 1, 2021 Regulatory Amendment

This guideline is being retired consequential to the September 1, 2021 Regulatory Amendment as the acceptable standards for operator protective structures are addressed by the amended section 16.33 of the OHS Regulation.

G16.22 Rollover protective structures (ROPS)

Issued February 27, 2001; Revised February 25, 2013; Editorial Revision April 6, 2020; Retired consequential to September 1, 2021 Regulatory Amendment

This guideline is being retired consequential to the September 1, 2021 Regulatory Amendment as the amended section 16.34 of the OHS Regulation allows for a risk assessment to determine whether a ROPS is necessary.

G16.24 ROPS certification - Damaged sweep arms

Issued August 1999; Revised February 25, 2013; Retired consequential to September 1, 2021 Regulatory Amendment

This guideline is being retired consequential to the September 1, 2021 Regulatory Amendment as a new section (26.54.1) on damaged sweep arms has been added to the OHS Regulation.

G16.28 Guarding moving parts on mobile equipment

Issued August 1999; Revised December 21, 2009; Retired consequential to September 1, 2021 Regulatory Amendment

This guideline is being retired consequential to the September 1, 2021 Regulatory Amendment as the amended section 16.32 of the OHS Regulation identifies the requirements for safeguarding moving parts.

G16.33 Use of seatbelts on forklifts

Issued June 18, 2008; Revised consequential to February 1, 2013 Regulatory Amendment; Retired consequential to September 1, 2021 Regulatory Amendment

This guideline is being retired consequential to the September 1, 2021 Regulatory Amendment as lift trucks are now consolidated under section 16.43 in the amended OHS Regulation with updated standards that refer to manufacturers' use and requirements of seat belts.

G16.44(2) Acceptable standard for load restraint

Issued February 11, 2009; Retired consequential to September 1, 2021 Regulatory Amendment

This guideline is being retired consequential to the September 1, 2021 Regulatory Amendment as the amended section 16.12(2) of the OHS Regulation no longer requires "meets a standard acceptable to the Board."

The following guidelines were retired prior to September 1, 2021.

G16.3, 16.19, 16.20 (and 4.3(2)) Welding repair of forks on lift trucks

Issued August 1999; Editorial Revision April 2005; Retired April 30, 2015

Refer to guideline G4.3(2) Welding repair of forks and fork extensions on lift trucks.

G16.22(2) Use of ROPS on agricultural tractors when operated on steep slopes or narrow roadways

Issued January 1, 2005; Retired consequential to February 1, 2012 Regulatory Amendment