Contents

GENERAL REQUIREMENTS

G8.2(3) Responsibility to provide

G8.3 Ensuring adequate fit of personal protective equipment

G8.5 Program

G8.5(b) Special program option for pulp and paper industry

G8.10 Personal clothing and accessories

SAFETY HEADGEAR

G8.11(1) Safety headgear

G8.11(2) Activity specific safety headgear

G8.11(2)-1 Safety headgear standards

G8.11(2)-2 Activity specific safety headgear - Ski helmets

G8.11(3) Protection from electrical hazards

G8.11(4) Chin straps

G8.12/8.13 Use of safety headgear for workers on ATVs and similar equipment in agricultural operations

G8.13 Use of safety headgear with bicycles and skates

EYE AND FACE PROTECTION

G8.15(1) Prescription safety eyewear - Alternate standards [Retired]

G8.17(2) Face protection - Alternate standards [Retired]

LIMB AND BODY PROTECTION

G8.21 Leg protection [Retired]

G8.21(2) Leg protection - Alternate standards [Retired]

G8.21(2)-1 Leg protection - WorkSafeBC standards [Retired]

G8.21(2)-2 Leg protection - Alternate standard

FOOTWEAR

G8.22 Footwear

G8.22(2.1) High heels and healthy footwear

G8.22(3) Specific safety protective features

G8.22(3)-1 Footwear - Alternate standards

HIGH VISIBILITY AND DISTINGUISHING APPAREL

G8.24 High visibility apparel

G8.24-1 Alternative standards for high visibility apparel [Retired]

BUOYANCY EQUIPMENT

G8.26(3) Buoyancy equipment and fall protection

G8.27-1 Compliance with standards

G8.27-2 Alternative acceptable standard for buoyancy equipment

G8.28 Working alone or in isolation with a hazard of drowning

RESPIRATORS

G8.33-1 Respiratory protection - Selection

G8.33-2 Scott II and IIA SCBA regulator donning switch hazard [Retired]

G8.33(1) Selection of respiratory protection - Alternate standard

G8.33(2)-1 Approved respirators

G8.33(2)-2 Interchange of equipment components [Retired]

G8.34-1 Protection factors

G8.34-2 Assigned protection factors for non-powered filtering facepiece style air-purifying respirators [Retired]

G8.34-3 Maximum use concentration and IDLH

G8.34-4 Protection factors - standard acceptable to WorkSafeBC

G8.34-5 Assigned protection factor for helmet/hood style powered air purifying respirators [Retired]

G8.35 IDLH or oxygen deficient atmophere

G8.38(2) Respiratory protection and use of contact lenses

G8.40 Respiratory protection - Fit test

G8.40(2.1)(c) Single-use respirators and fit test equivalency

G8.41 User seal check - Alternate standard

G8.42 Medical assessment

G8.44 Records

G8.45 Maintenance and inspection of self-contained breathing apparatus

Guidelines - Part 8 - General Requirements

G8.2(3) Responsibility to provide

Issued August 1999; Editorial Revision February 1, 2008

Regulatory excerpt

Section 8.2(3) of the OHS Regulation ("Regulation") states:

If the personal protective equipment provided by the employer causes allergenic or other adverse health effects, the employer must provide appropriate alternative equipment or safe measures.

Purpose of guideline

The purpose of this guideline is to provide an example of selecting alternative equipment if the personal protective equipment provided by the employer causes allergic or other adverse health effects.

Appropriate alternative equipment

An example of selecting appropriate alternative equipment would be a worker allergic to natural rubber latex gloves, but who has work duties resulting in exposure to blood or other body fluids (a potential exposure to biological agents designated as a hazardous substance in section 5.1.1). In such a circumstance, the worker could use gloves made of vinyl, nitrile, neoprene, copolymer, or polyethylene, which would be appropriate alternatives to latex gloves for this particular exposure. See also OHS Guideline G6.34-2 for more information.

If a worker has an allergenic or other adverse health effect due to the protective equipment supplied and the remedy chosen is the use of "other safe measures," such measures have to provide at least equivalent protection to the worker that the personal protective equipment normally used would provide.

G8.3 Ensuring adequate fit of personal protective equipment

Issued November 29, 2022

Regulatory excerpt

Section 8.3(1) of the OHS Regulation ("Regulation") states:

(1) Personal protective equipment must

(a) be selected and used in accordance with recognized standards, and provide effective protection,

(b) not in itself create a hazard to the wearer,

(c) be compatible, so that one item of personal protective equipment does not make another item ineffective, and

(d) be maintained in good working order and in a sanitary condition.

Purpose of guideline

The purpose of this guideline is to assist employers understand their obligation to ensure personal protective equipment (PPE) provided under section 8.2 of the Regulation provides effective protection to workers and does not in itself create a hazard to the wearer.

Importance of proper fit

Protective clothing and other equipment are generally sized around the average height and proportions of men. This is because men have historically made up the majority of workers in industries that require PPE. When different sized garments are created, they are often based on the same relative proportions, and as such may not properly fit all body shapes and sizes. For example, smaller sizes may still not provide a proper fit for women, or for others whose bodies don’t conform to this "standard."

Improperly fitting PPE may not provide effective protection and may lead to preventable injuries caused by tripping, entanglement, distractions, or restricted movement. Furthermore, workers may be dissuaded from wearing PPE that is uncomfortable, makes accessing the toilet or personal hygiene difficult, or that increases the effort required to perform tasks. Difficulties in finding PPE that fits properly may result in workers leaving industries with PPE requirements.

The following table illustrates some examples of how poorly fitting PPE can lead to preventable injuries:

| Type of PPE | Signs of misfit | Potential hazards | Head and face — hard hats, welding helmets, face shields | • Cannot tighten (or loosen) enough to provide a good fit • May feel unbalanced and bulky, even when properly adjusted |

• Poor fit may cause pinch-points, headaches, neck or shoulder strain • May obstruct vision • May result in distraction |

| Eye protection — safety glasses and goggles | • Safety glasses may be too wide (or small) across, too long (or short) at the temple, and/or too big (or small) in the bridge area | • Glasses may slip down nose, leaving eyes and face exposed to hazards • Poor fit may create gaps in coverage, allowing debris to enter eyes • Fogging may impact vision • May result in distraction |

| Hearing protection | • Earplugs may be too large or too small for ear canal • Earmuffs may be too heavy or not adjustable enough to fit snugly and comfortably |

• PPE may fall out or off when moving • May fail to provide adequate protection from noise |

| Respiratory protection | • Tight fitting respirators may not achieve adequately seal with all faces • Poor fit may result in failed fit test (as required by section 8.40 of the Regulation) • May have to over-tighten straps or use strap attachments to achieve seal |

• Ineffective seal with face may result in exposure to hazardous substances and associated health effects • Over-tightening respirator straps to compensate for poor fit may result in headaches, skin irritation and injury, discomfort, and/or distraction • Discomfort as a result of poor fit may result in worker adjusting respirator while in use, decreasing effectiveness of seal • Attachments used to tighten respirator straps may loosen over time, resulting in loss of protection |

| Fall protection, climbing, rope access, rescue, harnesses | • Harnesses that are too large may be unable to tighten enough to fit body properly • Harnesses that are too small may be too tight and limit freedom of movement • Improper location or alignment of load-bearing straps or buckles • Workers with significant breast tissue may find standard harnesses uncomfortable and ineffective |

• Equipment that is too loose may result in serious injury in the event of a fall • Equipment that is too tight may hinder workers' movements and their ability to walk safely • Ineffective protection • Cross-over style harnesses may provide better adjustability, comfort and fit |

| Torso and limbs — coveralls, Tyvek suits, fire-resistant clothing, lab coats, high-visibility apparel, chainsaw pants | • Arms or legs that are too short or too long • Shoulder span that is too short or too long • Tightness or looseness of fit where the legs meet the torso • Shirts, jackets, or vests that will not close properly across chest or stomach, or gaping when closed due to an excess of fabric • Shirts, jackets, or vests that are too long or too short • One-piece suits that hinder personal hygiene requirements |

• Slipping or tripping • Entanglement in moving equipment • Restricted movement of arms or legs • May cause distractions • Inadequate protection • May discourage drinking and taking healthy washroom breaks (which can lead to heat stress, kidney problems, or other illnesses) |

| Hands | • Gloves that are too big or too small in finger length and palm width

• Gloves that are too wide or too loose at the wrist • May restrict circulation to hand, causing loss of dexterity |

• May get hung up or entangled in equipment • Extra fabric may require extra exertion and undue pressure on hands • May increase perspiration, leading to fatigue and related injuries • May allow debris to fall into glove |

| Feet | • Safety footwear that is too big or too small in ankle, foot shape, or arch placement • Safety footwear molded to an incorrect gender resulting in poor fit and proportion, including incorrect flex point |

• Lack of adequate toe protection • Tripping hazard • Poor arch support • Blisters, infections • Repetitive strain injuries • Poor posture • Plantar fasciitis • Fallen arches • Secondary injuries to knees, hips, spine, or neck |

Attempting to modify poorly fitting PPE may decrease or eliminate the equipment’s protective qualities, and may not be permitted under the applicable standards.

Ensuring fit

Section 8.3(1) of the Regulation requires PPE to be selected and used in accordance with recognized standards. Current versions of CSA standards for most PPE include requirements to ensure adequate fit.

WorkSafeBC prevention officers who observe workers wearing poorly fitting PPE may address this issue under sections 8.3(1)(a) or (b) of the Regulation, as applicable.

What employers can do

Employers should consider the physical characteristics of the workforce requiring PPE and stock appropriate sizes and models to ensure correct sizing and appropriate fit. Equipment suppliers may be able to assist employers and workers to identify PPE that fits properly through the provision of sizing charts, fitting samples, and fit instructions.

For additional information on fit requirements, including information on how to measure proper fit, employers should speak with equipment suppliers and refer to relevant safety standards. For example, the following CSA standards provide guidance on selection and use of certain protective equipment:

- CAN/CSA-Z96.1-08 Selection, Use and Care of High-Visibility Safety Apparel

- CAN/CSA-Z94.3.1-16 Selection, Use, and Care of Eye and Face Protectors

- CAN/CSA-Z259.17-16 Selection and Use of Active Fall-protection Equipment and Systems

- CAN/CSA-Z195.1-02 Selection, Care, and Use of Protective Footwear

Under the provision of section 8.9 of the Regulation, workers who are required to use PPE must use equipment in accordance with training and instruction, inspect equipment before use, and report any equipment malfunction to the supervisor or employer. In accordance with these requirements, workers should confirm that PPE fits, provides effective protection, does not create a hazard itself, and does not negatively impact their mobility or freedom of movement.

G8.5 Program

Issued August 1, 1999; Revised November 17, 2003; Editorial Revision to include February 1, 2011 regulatory amendment

Regulatory excerpt

Section 8.5 of the OHS Regulation ("Regulation") states:

If personal protective equipment is required to protect against a chemical exposure or an oxygen deficient atmosphere the employer must implement an effective protective equipment program at the workplace which includes

(a) a statement of purpose and responsibilities,

(b) written procedures for selection, use, inspection, cleaning, maintenance and storage of protective equipment, when required,

(c) instruction and training in the correct use and maintenance of the equipment,

(d) for respirators, medical assessment of respirator wearers, when required,

(e) documentation when required, and

(f) program review.

Purpose of guideline

The purpose of this guideline is to provide direction in determining if personal protective equipment is required in a chemical exposure or an oxygen-deficient atmosphere.

Personal Protective Equipment

To determine if personal protective equipment is required in a workplace to protect against a chemical exposure or an oxygen-deficient atmosphere, the employer has to consider the requirements of section 5.55 of the Regulation. Section 5.55(1) states "If there is a risk to a worker from exposure to a harmful substance by any route of exposure, the employer must eliminate the exposure, or otherwise control it below harmful levels and below the applicable exposure limit established under section 5.48...." Options available to the employer include substitution, engineering control, administrative control, or personal protective equipment. However, section 5.55(3) states: "The use of personal protective equipment as the primary means to control exposure is permitted only when

(a) substitution, or engineering or administrative controls are not practicable, or

(b) additional protection is required because engineering or administrative controls are insufficient to reduce exposure below the applicable exposure limits, or

(c) the exposure results from temporary or emergency conditions only."

For guidance in determining whether personal protective equipment is required, refer to OHS Guideline G5.55.

For guidance on determining if a medical assessment of a respirator wearer is required under paragraph 8.5(d), refer to OHS Guideline G8.42.

G8.5(b) Special program option for pulp and paper industry

Issued August 1, 1999; Editorial Revision June 30, 2021

Regulatory excerpt

Section 8.5(b) of the OHS Regulation ("Regulation") states:

8.5 If personal equipment is required to protect against a chemical exposure or an oxygen deficient atmosphere the employer must implement an effective protective equipment program at the workplace which includes…

(b) written procedures for selection, use, inspection, cleaning, maintenance and storage of protective equipment, when required

Purpose of guideline

The purpose of this guideline is to address a maintenance requirement for escape respirators used in the pulp and paper industry, specifically the replacement schedule for chemical cartridges used for protection against reduced sulfur gases, such as hydrogen sulfide, methyl mercaptan, dimethyl mercaptan, dimethyl sulfide and dimethyl disulfide. Escape respirators, except for workers required to ride in the pulp mill elevators, may be half facepiece respirators and mouthpiece, or biteblock respirators, and are used by mill personnel to escape to a safe area when the mill experiences a gas leak.

Escape respirators

The performance of escape cartridges in the pulp and paper environment was assessed in a study conducted by BC Research Incorporated, and the findings were published in June 1994, in a report entitled "Life Expectancy of Cartridges for Escape Respirators: Final Report", BCRI Project No. 4-02-394. Based on the findings of this study, the following guidelines are recognized as acceptable practice by WorkSafeBC. (This guide was initially published by the Prevention Division in a letter issued October 6, 1994, to the pulp and paper industry.)

The replacement schedule for chemical cartridges for use in escape respirators, in the pulp and paper industry only, may be extended to 12 months for unused, unexposed, and undamaged cartridges with the following provisos:

- A cartridge in an escape respirator is to be changed after use in an emergency involving exposure to mill gases

- Each cartridge is to be marked to show clearly its expiry date

- A metal type cartridge is to be inspected prior to installation for dents in the base or threads

- Any damaged unit is to be replaced

Respiratory protection program

Each pulp and paper mill is expected to have a comprehensive respiratory protection program, functioning as required by section 8.5 of the Regulation. This is achieved when all workers who are, or may be, required to use a respirator are trained to an acceptable level of competency and all the elements of the program are in place covering correct use, limitations, maintenance and storage requirements for the devices selected.

For respirator use in industries other than pulp and paper mills, the employer must follow the respirator manufacturer's recommendations for cartridge replacement schedules.

G8.10 Personal clothing and accessories

Issued August 1, 1999; Revised September 22, 2015

Regulatory excerpt

Section 8.10(1) of the OHS Regulation ("Regulation") states:

The personal clothing of a worker must be of a type and in a condition which will not expose the worker to any unnecessary or avoidable hazards.

Purpose of guideline

This guideline provides clarification and examples of the regulatory requirements for personal clothing.

Clarifications for personal clothing

Under this section, the type and condition of clothing is a concern if a worker is exposed to injury from the material being handled, contact with an abrasive surface or object, or contact with a surface at a temperature that could cause a burn injury. For example, a worker handling hot tar or other material that could cause a burn through splashing, fuming, or radiant heat must wear suitable clothing covering the body and arms. A worker exposed to the abrasive action of material, such as the carrying of lumber on the shoulder or against the body, must wear appropriate clothing.

A worker may have to change or add clothing as the worker's job duties or work conditions change.

An employer may have a dress code or policy for clothing requirements during warm weather. WorkSafeBC prevention officers will not enforce an employer's policy of this type. Prevention officers will become involved in enforcement if the lack of appropriate clothing is exposing a worker to any unnecessary or avoidable hazards.

Removal of clothing during outdoor work in warm weather exposes workers to UV from the sun. Ultraviolet radiation from the sun is a "natural element," and under paragraph 8.2(1)(a) of the Regulation, a worker is responsible for providing any necessary clothing to protect against it. Workers and employers need to be aware of the hazard from solar radiation, and need to take measures to limit exposure, such as by use of appropriate attire and the use of sun block creams.

Guidelines - Part 8 - Safety Headgear

G8.11(1) Safety headgear

Issued September 1, 2021; Revised May 9, 2022

Regulatory excerpt

Section 8.11(1) of the OHS Regulation ("Regulation") states:

(1) Before a worker starts a work assignment in a work area where there is a risk of head injury to the worker from falling, flying or thrown objects, or other harmful contacts, the employer must take measures to

(a) eliminate the risk, or

(b) if it is not practicable to eliminate the risk, minimize the risk to the lowest level practicable by applying the following control measures in order of priority:

(i) engineering controls;

(ii) administrative controls;

(iii) requiring the worker to wear safety headgear.

Purpose of guideline

The purpose of this guideline is to provide information on identifying the risk of head injury from falling, flying, or thrown objects, or other harmful contacts, and controlling the risk by following the hierarchy of controls. This guideline also provides information about what to do if workers have concerns about the appropriateness of the control measures selected.

Background

Controlling exposures to hazards in the workplace is fundamental to protecting workers, but often personal protective equipment (PPE) such as safety headgear is used as a blanket first line of defense from a serious safety hazard. The Sikh community has raised concerns that those employers who use safety headgear as a blanket safety requirement are excluding turban-wearing Sikh workers from being able to fully participate in the workforce.

PPE is considered the least effective control measure as it does not eliminate a hazard but merely puts a barrier between the hazard and the worker. Following the hierarchy of controls ensures measures such as elimination, engineering controls, and administrative controls are applied before relying on safety headgear.

Worker participation

Creating and managing a safe and healthy workplace involves everyone. For workers to be truly engaged in health and safety, they need to know their employer and supervisor value their well-being and their input. Consult with workers in the identification of any workplace hazards and in assessing the risks of injury as they will have direct knowledge of workplace conditions.

Identify hazards, and assess and control risks

To help eliminate or reduce the risk of head injury, employers, in consultation with their workers, can take these steps:

- Identify the hazards

- Assess the risks

- Control the risks

The first step is to determine if there are any hazards that may cause a head injury to a worker. A "hazard" is anything with the potential to cause an injury to a worker. An example of a hazard would be any tool or other object that could fall on a worker from above. Consider the workplace and its layout, as well as the work tasks or activities that pose hazards to workers.

A "risk" is the chance of injury when an individual is exposed to a hazard. In determining the level of risk a hazard poses, the following factors are considered:

- What kind of injury or illness could be suffered, and how severe would it most likely be?

- How long workers are typically exposed to the hazard? The longer the exposure, the higher the risk.

- How frequent is the exposure? If the task is repeated many times each shift, it carries more risk than a task done only occasionally.

Examples include if there is a risk of a worker being struck by a falling tool or other object, or if there is a potential for workers to enter an area where the hazard exists.

Where a hazard exists and there is a risk of injury to any worker, the employer must take reasonable measures to eliminate that risk. Eliminating the dangers of worker head injury eliminates the need for head protection. If it is not reasonably practicable to eliminate the risk, the employer must continue to follow the hierarchy of controls and minimize the risk to the lowest level practicable.

For further information on hazard identification, risk management, and controls please refer to Managing risk webpage on worksafebc.com.

The hierarchy of controls

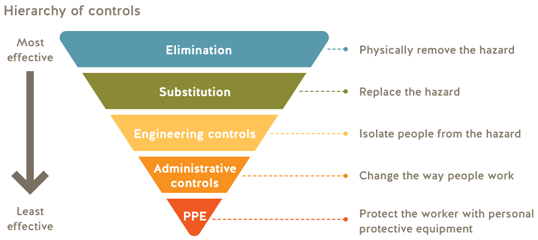

The hierarchy of controls is a system for controlling risk in the workplace. It is a step-by-step approach to eliminating or reducing risks, and it ranks risk controls from the highest level of protection and reliability to the lowest. The hierarchy of controls, in the order of priority, is shown below.

While the controls are listed in order of effectiveness, reducing the risk may involve using a single risk control or two or more different controls in combination. For example, first responders may encounter circumstances where the risks cannot be completely eliminated before entering a burning building, but engineering controls, administrative controls, and/or PPE can be used to minimize the risks to workers.

1-2 Elimination or substitution

The most effective control measure involves eliminating the hazard and its associated risk. Eliminating the dangers of worker head injury eliminates the need for head protection. Substitution involves replacing the material or process with a less hazardous one.

When considering these options, determine if there is a safer way to perform the task. For example, if materials need to be delivered to a construction site where there is a risk of head injury to the worker from falling, flying, or thrown objects, can a safe zone be set up on the site where no risk exists? This is an example of an elimination control measure removing the hazard and its associated risk.

3 Engineering controls

If it is not practicable to eliminate the hazards or if there are no safer alternatives, engineering controls are the next best option. These involve using work equipment or other means to prevent workers from being exposed to a hazard. Engineering controls are physical changes to the workplace. Engineering controls focused on head injury risks may include measures such as the following:

- Safety nets to prevent objects from falling

- Temporary or permanent solid barriers to prevent objects from falling, being thrown, or sent flying from work areas

- Temporary or permanent barriers to prevent workers from entering hazard areas

- Tethering and securing tools, materials, and equipment so they cannot fall

- Changing the workplace so workers do not need to enter areas where a risk of head injury exists — for example, in a manufacturing plant, ensuring manual assembly or packing areas are separated from the areas where overhead bridge cranes operate

4 Administrative controls

Administrative controls involve identifying and implementing safe work procedures so workers can perform their job duties safely. The assessment will form the basis of these safe work procedures, which may include the following:

- Procedures requiring work to stop when other workers are beneath their work areas

- Creating work practices that eliminate the exposure to the hazard — for example, workers delivering materials by truck to a worksite with overhead hazards may need to be restricted to a designated area where no overhead hazard exists

- Creating designated pedestrian walkways that keep workers out of head injury hazard zones — this would be similar to those used in distribution warehouses for forklift traffic

- Using signs to alert workers to overhead hazard areas, and provision for safety headgear for entering those areas

- Using spotters to alert workers to vacate areas when moving elevated loads or long loads that have the potential to fall or swing and strike a worker — for example, on an industrial site where a stinger is moving a long pipe, or a fabrication shop where an overhead crane is moving a steel beam section

5 Personal protective equipment

PPE is another important control to protect workers and refers to anything workers use or wear to minimize risk to a hazard. However, PPE, such as safety headgear, provides the lowest level of protection and should ideally be used in combination with other control measures. Safety headgear such as hard hats must be worn by workers if it is not practicable to eliminate the risk of head injury, or engineering and/or administrative controls are not adequate to minimize the risk of head injury to the lowest level practicable.

An example of where safety headgear may be necessary is if the work environment is constantly changing and it is not possible to use engineering or administrative controls to minimize the hazards to the level needed to protect workers from the risk of head injury.

Employers must take reasonable measures to eliminate or control those hazards for which PPE is required, including safety headgear.

Document, communicate, and review the safety headgear assessment

Employers have a duty under the Workers Compensation Act to provide workers with the information, instruction, training, and supervision necessary to ensure their health and safety. Documenting and communicating the assessment and controls to everyone affected will help employers meet these obligations. A failure to do so severely undermines a worker’s knowledge of the risks that may be encountered in their work environment.

Communicate with:

- All affected workers, particularly if the controls involve changes in their work processes (e.g., use of spotters, new signage to be followed, tethering tools and materials)

- Supervisors of affected workers

- The joint health and safety committee (or worker health and safety representative), if applicable

- All other people (e.g., visitors, clients) who need to follow safety procedures in areas with a risk of head injury

Monitor and update

Managing workplace risks is an ongoing process. Employers need to monitor the effectiveness of the control measures in place and improve those that are not working as intended. Continue to engage workers throughout the monitoring and updating of the risk management plan.

Role of WorkSafeBC prevention officers

If a worker has a concern about the measures taken to eliminate or reduce the hazard they should first speak to their employer or supervisor to determine if further control measures are possible. If there is still a concern regarding the appropriateness of the control measure(s) selected, the worker or employer may choose to call a prevention officer for assistance. In these circumstances, the prevention officer will review the employer's assessment and determine whether the hierarchy of controls has been followed and applied before relying on safety headgear.

In some situations, employers may have to balance their health and safety obligations with their obligations under human rights legislation. For more information on this please refer to OHS Guideline G-P2-21(1).

Additional resources

To help with assessing and controlling the risks of head injury in the workplace, WorkSafeBC has developed a resource, Safety headgear: Assessing and controlling risk of head injury. A Safety headgear: Risk management template is also available to help document workplace risks and the steps to take to control those risks.

Safety headgear: Rights and responsibilities is also available for workers, with information on their rights and what they can do if they have a concern with an employer's application of section 8.11 of the Regulation in their workplace. This resource includes a process map that outlines what workers can do if they have concerns with the employers' decision to rely on safety headgear.

G8.11(2) Activity specific safety headgear

Issued August 1, 1999; Editorial Revision April 2005; Revised August 1, 2013; Editorial Revision consequential to February 1, 2015 Regulatory Amendment; Editorial Revision consequential to June 3, 2019 Regulatory Amendment; Editorial Revision consequential to September 1, 2021 Regulatory Amendment

Regulatory excerpt

Section 8.11 of the OHS Regulation ("Regulation") states:

(1) Before a worker starts a work assignment in a work area where there is a risk of head injury to the worker from falling, flying or thrown objects, or other harmful contacts, the employer must take measures to

(a) eliminate the risk, or

(b) if it is not practicable to eliminate the risk, minimize the risk to the lowest level practicable by applying the following control measures in order of priority:

(i) engineering controls;

(ii) administrative controls;

(iii) requiring the worker to wear safety headgear.

(2) Safety headgear must meet the requirements of one of the following standards:

(a) CSA Standard CAN/CSA-Z94.1-05 or CAN/CSA-Z94.1-15, Industrial protective headwear – Performance, selection, care, and use;

(b) ANSI Standard ANSI/ISEA Z89.1-2009 or ANSI/ISEA Z89.1-2014, American National Standard for Industrial Head Protection.

Section 4.4(2)(a) of the Regulation states:

(2) When this Regulation requires a person to comply with

(a) a publication, code or standard of the Board or another agency, the person may, as an alternative, comply with another publication, code or standard acceptable to the Board …

Purpose of guideline

This guideline outlines alternate standards for safety headgear for specific types of activities and describes when they are applicable.

Acceptable standards

WorkSafeBC accepts the following alternate standards for safety headgear designed for specific types of activity:

- Union of International Alpine Association Standard (UIAA) Standard 106 Mountaineering and Climbing Equipment Helmets "Rock Climbers Helmets" (for emergency rescue operations, rock scaling, silviculture operations, window washers, and workers doing boatswain's chair work)

Headgear meeting this standard protects against blunt impact hazards to the head, but must not be used in place of conventional safety headgear whenever the ventilation holes may expose the worker to hazards from small rigid objects such as nails or if flame resistance is required.

- CAN/CSA Z262.1-M90 (R2007) Ice Hockey Helmets (for on-ice activities)

- CAN/CSA Z611-M86 Police Riot Helmets and Face Shield Protection (for crowd control/riot squad duties)

Since helmets meeting these three standards are not made or tested for dielectric properties, they are not suitable for environments where exposed energized electrical wires or equipment may be present.

This guideline and these standards do not apply to ski helmets. Please refer to OHS guideline G8.11(2)-2 Activity specific safety headgear — Ski helmets.

G8.11(2)-1 Safety headgear standards

Issued September 21, 2012; Revised consequential to June 3, 2019 Regulatory Amendment

Regulatory excerpt

Section 8.11(2) of the OHS Regulation ("Regulation") states:

(2) Safety headgear must meet the requirements of one of the following standards:

(a) CSA Standard CAN/CSA-Z94.1-05 or CAN/CSA-Z94.1-15, Industrial protective headwear – Performance, selection, care, and use;

(b) ANSI Standard ANSI/ISEA Z89.1-2009 or ANSI/ISEA Z89.1-2014, American National Standard for Industrial Head Protection.

Purpose of guideline

The purpose of this guideline is to help clarify the requirements in the approved standards around the use of Type 1 or Type 2 safety headgear.

Acceptable standards

Both 2005 CSA Standard and 2009 ANSI Standard classify safety headgear into two types: Type 1 and Type 2. Type 1 safety headgear provides protection from impacts and sharp objects from above. Type 2 safety headgear provides protection from impacts and sharp objects from above and sides. WorkSafeBC permits the use of both types of safety headgear providing the other requirements in the applicable standards are met.

Type 2 safety headgear provides more protection where there is a possibility of objects striking the side of the head.

G8.11(2)-2 Activity specific safety headgear — Ski helmets

Issued August 1, 2013; Editorial Revision consequential to June 3, 2019 Regulatory Amendment; Editorial Revision consequential to September 1, 2021 Regulatory Amendment

Regulatory excerpt

Sections 8.11(1) and (2) of the OHS Regulation ("Regulation") state:

(1) Before a worker starts a work assignment in a work area where there is a risk of head injury to the worker from falling, flying or thrown objects, or other harmful contacts, the employer must take measures to

(a) eliminate the risk, or

(b) if it is not practicable to eliminate the risk, minimize the risk to the lowest level practicable by applying the following control measures in order of priority:

(i) engineering controls;

(ii) administrative controls;

(iii) requiring the worker to wear safety headgear.

(2) Safety headgear must meet the requirements of one of the following standards

Section 8.3(2) of the Regulation states:

If the use of personal protective equipment creates hazards equal to or greater than those its use is intended to prevent, alternative personal protective equipment must be used or other appropriate measures must be taken.

Section 4.4(2)(a) of the Regulation states:

(2) When this Regulation requires a person to comply with

(a) a publication, code or standard of the Board or another agency, the person may, as an alternative, comply with another publication, code or standard acceptable to the Board …

Purpose of guideline

The purpose of this guideline is to clarify the requirements for safety helmets for workers engaged in skiing or snowboarding, and to identify acceptable alternate standards for these helmets.

Use of helmets for skiing or snowboarding

Section 8.11(1) of the Regulation states that, where there is a risk of head injury from harmful contacts, employers must attempt to eliminate or minimize those risks. If the risk cannot be eliminated or minimized, workers must wear safety headgear.

Work activities performed while engaging in alpine, or downhill, skiing or snowboarding present a danger of harmful contacts. These harmful contacts include possible contact with the ground, moving or stationary objects, and other persons. Risks of harmful contacts cannot be easily eliminated or minimized in this type of environment. Accordingly, workers engaged in sliding activities will usually be required to wear safety headgear.

In ski areas, examples of workers typically engaged in skiing or snowboarding include ski patrollers, ski instructors, avalanche control workers, and workers transiting on skis or snowboards between work locations.

Acceptable standards

Section 8.11(2) lists standards that safety headgear must meet. In addition, section 4.4(2)(a) permits the reliance on other standards that are acceptable to WorkSafeBC. WorkSafeBC has identified the following standards for safety headgear for skiing and snowboarding work activities as acceptable for use by workers:

- CE-EN1077 Helmets for alpine skiers and snowboarders — Class A or Class B

- ASTM F2040 Helmets Used for Recreational Snow Sports

- Snell RS-98 Protective Headgear for Recreational Skiing and Snowboarding

Risk assessment

Where an employer can show that a particular sliding activity is performed in a way that the danger of harmful contacts is not present, or the risk has been minimized to the lowest level practicable, workers may perform that activity without headgear. In making such a determination, the employer is required to perform a thorough risk assessment showing that the danger of harmful contacts is not present.

Employers should consider whether wearing safety headgear for a particular activity where headgear would normally be required, would itself create a hazard to the worker in the circumstances. As stated in section 8.3(2), personal protective equipment must not itself create a hazard to the wearer. For example, a worker engaged in avalanche control blasting whose ability to communicate clearly with co-workers is impaired by headgear, may need to remove it for the duration of that activity.

G8.11(3) Protection from electrical hazards

Issued August 1, 1999; Editorial Revision consequential to June 3, 2019 Regulatory Amendment

Regulatory excerpt

Section 8.11(3) of the OHS Regulation ("Regulation") states:

If a worker may be exposed to an electrical hazard the safety headgear must have an appropriate non-conductive rating.

Purpose of guideline

The purpose of this guideline is to define the appropriate type of safety headgear required under section 8.11(3) of the Regulation when a worker may be exposed to electrical hazards.

Background

Only electricians, powerline technicians (formerly known as linemen), and certified utility arborists will normally be exposed to electrical hazards, which result when exposed and energized electric wires or electrical equipment is present in the workplace. Firefighters may be exposed to electrical hazards during fire or other emergency incidents, and their headwear requirements during such activity are specified in Part 31 of the Regulation.

The CSA (CAN/CSA-Z94.1-05 and CAN/CSA-Z94.1-15) and ANSI (ANSI/ISEA Z89.1-2009 and ANSI/ISEA Z89.1-2014) Standards for safety headgear designate headgear as Class G (General) for a dielectric test rating, when new, of 2,200 volts.

The CSA (CAN/CSA-Z94.1-05 and CAN/CSA-Z94.1-15) and ANSI (ANSI/ISEA Z89.1-2009 and ANSI/ISEA Z89.1-2014) Standards for safety headgear designate headgear as Class E (Electrical) for a dielectric test rating, when new, of 20,000 volts.

Both the CSA and ANSI standards warn that dielectric rated headgear is intended to reduce risks arising from accidental contact with energized electrical equipment, not to provide a primary means of insulating a worker from intentional contact with such equipment.

Appropripate dielectric rating

An electrician working only on "residential type" circuits, of 240 volts or less, may wear Class A, B, G, or E rated CSA or ANSI safety headgear. This upper voltage limit for work around residential type circuits may seem conservative, but the 2,200 volt dielectric rating for these classes of headgear is achieved when testing a new sample, and the protection degrades with use and is also dependant on the cleanliness of the headgear.

Powerline technicians, electricians, and any other workers who work on circuits that have the potential for voltages above 240 volts need to wear Class B or E rated CSA or ANSI headgear, or equivalent.

Class C (Conductive) CSA or ANSI safety headgear does not provide dielectric protection. Any safety headgear that has had holes drilled in the shell to install accessories is considered to have lost its dielectric rating. Workers (other than electricians, certified utility arborists or powerline technicians who should not be exposed to energized electric wires or equipment in the normal course of their work), may wear headgear with whatever class of dielectric protection they desire. If workers receive special training and are given work assignments requiring work near exposed energized electrical sources, they must have and wear headgear with the appropriate dielectric rating. For example, workers assigned to clean and paint utility poles may be exposed to electrical hazards, and should wear electrically protective headgear.

G8.11(4) Chin straps

Issued August 1, 1999; Editorial Revision consequential to June 3, 2019 Regulatory Amendment

Regulatory excerpt

Section 8.11(4) of the OHS Regulation ("Regulation") states:

Chin straps or other effective means of retention must be used on safety headgear when workers are climbing or working from a height exceeding 3 m (10 ft), or are exposed to high winds or other conditions that may cause loss of the headgear.

Purpose of guideline

This guideline outlines that chin straps are an effective means for the retention of safety headgear as required by section 8.11(4) of the Regulation.

Background

Industrial safety headgear has traditionally been designed and tested to provide protection from an impact directed more or less downward onto the top of the head. The CSA Standard CAN/CSA-Z94.1-92 introduced a new requirement for protection of the head from an impact landing on the side of the head. This was in response to injury studies that indicated a significant incidence of injury due to people being struck on the side of the head by objects, even when wearing a safety headgear. During the development of the Regulation, expert advice provided to the Personal Protective Equipment Subcommittee drew attention to the severity and high cost of head injuries, particularly the many injuries which result from an impact to the side of the head. This type of head injury will typically occur when someone falls and strikes the floor, ground, or some other object. Head protection must remain in place on the head to provide any protection when the head strikes something during or at the end of a fall. This is the reason why bicycle helmets and headgear for many other sports have a chin strap. The expert advice to the regulation development process was industrial safety headgear should have a mandatory headgear retention criteria, to assist with keeping safety headgear in place during work, including the headgear remaining effectively in place during a fall. Hence, section 8.11(4) was established.

Criteria of safety headgear

This section has three main objectives:

- To keep safety headgear in place on the wearer's head during a fall.

- To keep safety headgear from becoming a falling object and a danger to workers working below.

- To ensure the worker remains protected by safety headgear while doing work tasks. (For example, a rock scaler losing the safety headgear part way down a rappel of a rock face would have to descend the rest of the way down the rock face without head protection to recover the hat or get a replacement.)

Headgear may be accidentally knocked off a worker's head in any situation. Generally speaking, a means of retention should be used when the circumstances of the work create a likelihood of the loss of the headgear. Some examples are work on a ladder or scaffold over 10 feet high, or during work in an area with high wind (either natural wind or wind created by equipment such as a helicopter). Generally it is not expected a chin strap would need to be worn by a worker on a floor or deck enclosed by guardrails.

Retention test

CSA Standards Z94.1-05 and Z94.1-15 specify a retention test for hard hats that is intended to evaluate the stability of the headgear during normal use. The standard states that the "test does not assess the ability of the headgear to remain in place during extreme conditions (e.g., windy conditions, during an impact or fall)." Therefore, headgear meeting this aspect of the CSA standard does not automatically comply with section 8.11(4). At this time, for the purposes of section 8.11(4), a chin strap system is an effective means known to WorkSafeBC for the retention of safety headgear.

G8.12/8.13 Use of safety headgear for workers on ATVs and similar equipment in agricultural operations

Issued May 25, 2005; Editorial Revision June 30, 2021; Editorial Revision August 20, 2025

Regulatory excerpt

Section 8.12 of the OHS Regulation ("Regulation") states:

(1) Operators and passengers on all-terrain vehicles, snowmobiles and motorcycles must wear headgear meeting the requirements of

(a) CSA Standard CAN3-D230-M85, Protective Headgear in Motor Vehicle Applications,

(b) British Safety Institution Standard BS5361.1976, Specification: Protective Helmets for Vehicle Users, (as amended to 1981),

(c) Snell Memorial Foundation 1995 Standard for Protective Headgear for Use with Motorcycles and Other Motorized Vehicles, or

(d) US Federal Standard for Motorcycle Helmets (Title 49 — Transportation — Part 571.218).

(2) Headgear in good condition meeting earlier editions of a standard listed in subsection (1) may remain in service if purchased before April 15, 1998.

(3) When an all-terrain vehicle is operated within a specific location, with no rollover hazard area and no area containing a significant hazard that may cause loss of control and at a speed not exceeding 20 km/h (13 mph), safety headgear meeting the requirements of section 8.13 may be used in place of headgear specified in subsection 8.12(1).

Section 8.13 of the Regulation states:

(1) A worker riding a bicycle or using in-line skates or similar means of transport must wear headgear meeting the requirements of

(a) CSA Standard CAN/CSA-D113.2-M89, Cycling Helmets,

(b) Snell Memorial Foundation 1994 Standard for Protective Headgear for Use in Non-Motorized Sports, or

(c) Snell Memorial Foundation 1995 Standard for Protective Headgear for Use in Bicycling.

(2) If a bicycle or similar conveyance is operated at speeds not exceeding 20 km/h (13 mph) within a specific location, safety headgear meeting the requirements of section 8.11 is acceptable when worn with a chin strap.

Section 1.1 of the Regulation states, in part:

…

"rollover hazard area", with respect to mobile equipment, means an area that is comprised of

(a) grades or slopes that exceed

(i) the manufacturer’s maximum slope operating stability limit for the mobile equipment, or

(ii) 10%, if the manufacturer has not set a maximum slope operating stability limit for the mobile equipment, or

(b) open edges, open ramps, loading docks, ditches, drop-offs, holes, soft spots or mounds, or other terrain hazards, that may cause a rollover;

…

Purpose of this guideline

This guideline provides information on the requirements for safety headgear, under sections 8.12 and 8.13 of the OHS Regulation ("Regulation"), when workers use various types of small mobile equipment and other conveyances in agricultural operations. (Note that the responsibilities for providing safety headgear and other personal protective equipment are covered in section 8.2 of the Regulation.)

ATVs, snowmobiles, and motorcycles

These types of equipment are often used for work purposes in farming or ranching operations. Section 8.12(1) requires workers on such mobile equipment to wear head protection which meets at least one of the listed Canadian, American, or British standards. These standards are common, and suppliers will typically have headgear that is compliant.

Section 8.12(2) recognizes that older helmets may in some cases meet an earlier edition of the protective standard listed in the Regulation. In addition, it should be noted that under section 4.4 of the Regulation, WorkSafeBC can consider other standards as well. A farmer or rancher who would like to have an alternative standard considered should contact WorkSafeBC for a review of it.

For workers on ATVs, section 8.12(3) also permits the use of helmets meeting the bicycle and other non-motorized sports helmet standards listed in section 8.13(1), if the ATV is operated at speeds not exceeding 20 km per hour (13 mph) within a specific location where there is no rollover hazard area.

A "specific location" is defined in the Regulation as "a yard, plant, or other clearly defined and limited area in which mobile equipment is operated, but does not include an entire municipality, district, transient forestry operation or construction site." This definition indicates a specific location would be a particular defined area of a ranch or farm in which mobile equipment is used, rather than the whole property, unless the property was relatively restricted in size. Typically, such areas might be those in the vicinity of the dwellings, outbuildings, and nearby areas frequently used by mobile equipment.

A key factor is that the area must have no "rollover hazard area," which is defined in section 1.1 of the Regulation. In the case of ranches, the slope criterion will often be a limiting factor. On farms, areas adjacent to drainage or irrigation ditches would be considered to be rollover hazard areas.

Bicycles and similar conveyances

Bicycles are used in some agricultural operations such as greenhouses. When using bicycles, or similar conveyances such as in-line skates, section 8.13(1) requires that the worker wear safety headgear meeting one of the standards listed. The standards are common, and suppliers will usually have headgear that is compliant. Additional acceptable standards are identified in OHS Guideline G8.13.

In lower hazard circumstances, section 8.13(2) permits the use of "hard hats" with chin straps. To permit this use of a lower standard of protection, the bicycle is to be operated at speeds of not more than 20 km per hour (13 mph), within a specific location. Greenhouses are considered to be a specific location.

Utility vehicles

Sections 8.12 and 8.13 do not require the use of safety headgear while riding in utility vehicles or other such equipment not identified in the requirements. A utility vehicle typically has a steering wheel and seating that permits two persons to sit side by side, in contrast to an ATV which is equipped with a handle bar and a straddle seating arrangement. Examples of utility vehicles include "Gators" and "Argos".

In addition to the requirements of sections 8.12 and 8.13, section 4.3(1) of the Regulation requires that equipment be operated in conformity with manufacturers' instructions. If such instructions for utility vehicles require the use of safety headgear, then it is appropriate to select headgear meeting a standard listed in section 8.12. In all cases, to help ensure safety the operator should ensure the utility vehicle is operated in accordance with manufacturers' instructions, at prudent speeds, avoiding holes, debris and steep slopes.

Recreational use

Sections 8.12 and 8.13 apply only to the use of conveyances for work purposes. They do not apply to the personal use of such equipment for recreational purposes. When engaged in recreational use, people must comply with protective helmet requirements of the public authority with jurisdiction. Even if safety headgear is not required, it is recommended, for the purposes of safety, that it be worn.

8.13 Use of safety headgear with bicycles and skates

Issued June 30, 2021

Regulatory excerpt

Section 8.13(1) of the OHS Regulation ("Regulation") states:

(1) A worker riding a bicycle or using in-line skates or similar means of transport must wear headgear meeting the requirements of

(a) CSA Standard CAN/CSA-D113.2-M89, Cycling Helmets,

(b) Snell Memorial Foundation 1994 Standard for Protective Headgear for Use in Non-Motorized Sports, or

(c) Snell Memorial Foundation 1995 Standard for Protective Headgear for Use in Bicycling.

Section 4.4(2)(a) of the Regulation states:

(2) When this Regulation requires a person to comply with

(a) a publication, code or standard of the Board or another agency, the person may, as an alternative, comply with another publication, code or standard acceptable to the Board …

Purpose of guideline

Section 4.4(2)(a) of the Regulation provides WorkSafeBC the authority to accept alternative standards to those listed in the Regulation. The purpose of this guideline is to identify alternative bicycle helmet standards acceptable to WorkSafeBC.

Alternative standards

When using bicycles, or similar conveyances such as in-line skates, section 8.13(1) requires that the worker wears safety headgear meeting one of the standards listed. Alternative bicycle helmet standards acceptable to WorkSafeBC include the following:

- American Society for Testing and Materials Standard ASTM F1447-94 (Standard Specification for Protective Headgear Used in Bicycling), as amended from time to time

- Snell Memorial Foundation Standard N-94 (1994 Standard for Protective Headgear for Use in Non-Motorized Sports), as amended from time to time

- Snell Memorial Foundation Standard B-95 (1995 Standard for Protective Headgear for Use with Bicycles), as amended from time to time

- Snell Memorial Foundation Standard B-90 (1990 Standard for Protective Headgear for Use in Bicycling), as amended from time to time

The United States Consumer Product Safety Commission (CPSC) bike helmet standard is required by law in the United States. A CPSC sticker on a bike helmet is an indication that it meets the ASTM F1447-94 standard.

Guidelines - Part 8 - Eye and Face Protection

G8.15(1) Prescription safety eyewear – Alternate standards

Issued June 18, 2008; Revised May 9, 2014; Retired consequential to June 3, 2019 Regulatory Amendment

G8.17(2) Face protection - Alternate standards

Issued July 9, 2009; Revised October 28, 2015; Retired consequential to June 3, 2019 Regulatory Amendment

Guidelines - Part 8 - Limb and Body Protection

G8.21 Leg protection

Issued August 1, 1999; Editorial Revision October 2004; Retired May 31, 2021

G8.21(2) Leg protection - Alternate standards

Retired February 1, 2011

This guideline is not required since the referenced alternative standards have been incorporated into OHS Regulation section 8.21.

G8.21(2)-1 Leg protection - WorkSafeBC standards

Issued February 1, 2011; Retired June 30, 2021

G8.21(2)-2 Leg protection - Alternate standard

Issued May 29, 2018

Regulatory excerpt

Section 8.21(2) of the OHS Regulation ("Regulation") states:

(2) Leg protective devices referred to in subsection (1) must meet or exceed

(a) the general requirements of section 4 of the WorkSafeBC Standard - Leg Protective Devices, as set out in Schedule 8-A of this Part, and

(b) the performance requirements of one of the following standards, using the cut-resistance testing protocol set out in that standard except as varied in subparagraph (ii):

(i) WorkSafeBC Standard - Leg Protective Devices, as set out in section 5 of Schedule 8-A of this Part, applying a threshold chain speed of 18.3 metres per second or 3 600 feet per minute;

(ii) ASTM F 1414-04 Standard Test Method for Measurement of Cut Resistance to Chain Saw in Lower Body (Legs) Protective Clothing, but applying a threshold chain speed of 16.8 metres per second or 3 300 feet per minute;

(iii) ISO 11393-2 Protective clothing for users of hand-held chain-saws - Part 2: Test methods and performance requirements for leg protectors, applying a Class 2 threshold chain speed of 24 metres per second or 4 724 feet per minute;

(iv) BS EN 381-5:1995 Protective clothing for users of hand-held chain saws - Part 5: Requirements for leg protectors, applying a Class 2 threshold chain speed of 24 metres per second or 4 724 feet per minute.

Section 4.4(2) of the Regulation states:

(2) When this Regulation requires a person to comply with

(a) a publication, code or standard of the Board or another agency, the person may, as an alternative, comply with another publication, code or standard acceptable to the Board...

Purpose of guideline

The purpose of this guideline is to specify, for the purposes of section 8.21(2) of the Regulation, an alternate standard acceptable to WorkSafeBC for leg protection devices.

Acceptable standards

Section 4.4(2)(a) permits WorkSafeBC to accept another standard as an alternative to one referred to in the Regulation. WorkSafeBC had determined that ASTM F1414-15 is an acceptable alternate standard under section 8.21(2), when applying a threshold chain speed of 16.8 metres per second or 3,300 feet per minute.

Guidelines - Part 8 - Footwear

G8.22 Footwear

Issued August 1, 1999

Regulatory excerpt

Section 8.22(1) of the OHS Regulation ("Regulation") states:

A worker's footwear must be of a design, construction, and material appropriate to the protection required and that allows the worker to safely perform the worker's work.

Section 8.22(2) of the OHS Regulation states:

(2) To determine appropriate footwear under subsection (1), the following factors must be considered:

(a) slipping;

(b) tripping;

(c) uneven terrain;

(d) abrasion;

(e) ankle protection and foot support;

(f) potential for musculoskeletal injury;

(g) crushing potential;

(h) temperature extremes;

(i) corrosive substances;

(j) puncture hazards;

(k) electrical shock;

(l) any other recognizable hazard.

Purpose of guideline

The purpose of this guideline is to outline the requirement that the employer must determine the appropriate protection required for the feet and ankles based on the work assigned to each worker, and ensure each worker wears appropriate footwear, as stated in sections 8.22(1) and (2) of the Regulation.

Assessment

The assessment is based on whatever work procedures and arrangements exist in the workplace at any time. An employer may change the work procedures and arrangements to reduce or remove the risk. For example, an employer may limit the number of workers doing tasks that cause a risk of foot injury. Alternatively, the employer may change the way the tasks are done. Protective footwear need only be worn while a worker is exposed to the risk that requires it.

When determining the requirements for appropriate protective footwear, an employer should not consider training and supervision as a substitute for protective footwear.

The risk assessment to determine appropriate footwear will result in persons or activities being placed into one of three categories:

- The hazards present require "safety footwear." As safety footwear is only certified with respect to certain features to protect from specific types of hazard, regard must be had to whether there should be additional requirements to cover all hazards of a worker's job.

- There are some hazards present that require footwear to provide protection, but not necessarily protection to the level of "certified safety footwear." For example, a lifeguard at a beach likely will not need to wear footwear with safety toe protection, but needs to wear footwear that will protect against cuts from objects on a beach where there is a risk from such objects.

- There are no hazards of foot injury for which specific requirements are necessary. For example, this will be the case for most office workers.

G8.22(2.1) High heels and healthy footwear

Issued April 28, 2017

Regulatory excerpt

Section 8.22(2.1) of the OHS Regulation ("Regulation") states:

An employer must not require a worker to wear footwear that does not comply with subsection (1).

Section 8.22 of the Regulation states, in part:

(1) A worker's footwear must be of a design, construction, and material appropriate to the protection required and that allows the worker to safely perform the worker's work.

(2) To determine appropriate footwear under subsection (1), the following factors must be considered:

(a) slipping;

(b) tripping;

(c) uneven terrain;

(d) abrasion;

(e) ankle protection and foot support;

(f) potential for musculoskeletal injury;

(g) crushing potential;

(h) temperature extremes;

(i) corrosive substances;

(j) puncture hazards;

(k) electrical shock;

(l) any other recognizable hazard.

Purpose of guideline

This guideline provides clarification of the section 8.22(2.1) requirement that an employer must not require a worker to wear footwear that does not comply with section 8.22(1).

High heels

Under section 8.22(1), footwear must both allow the workers to perform their work safely and provide the protection required for the particular environment. In order to determine whether certain footwear is appropriate within the meaning of section 8.22(1), the factors listed in section 8.22(2) must be considered.

Walking in high heels (typically > 1.5 inches high) has been shown to significantly reduce ankle muscle movement as well as balance control. High heels have also been shown to result in musculoskeletal injury, particularly ankle and foot sprains and strains. High heels are therefore not appropriate with consideration to the factors of ankle protection and foot support, potential for musculoskeletal injury, and slipping, tripping, and uneven terrain. Where any of those hazards are present, high heels will not allow the workers to safely perform their work.

OHS Guideline G8.22 Footwear explains that the risk assessment employers must make to determine what constitutes appropriate footwear is based on the work assigned to each worker and on the work procedures and arrangements that exist in the workplace at any given time. The risk assessment should also consider the workplace floor and stair surfaces and whether there may be liquids or items on them that could be slip and trip hazards.

As an example, hospitality workers (e.g., servers, hosts, bus-people, and bartenders in bars, clubs, restaurants, or other hospitality venues) walk on different surfaces, including slippery surfaces and stairs, often while carrying food and drinks. With consideration to the factors referred to in section 8.22(2)(a), (b), (c), (e), and (f), high heels would not be appropriate footwear. A dress code requiring hospitality workers to wear high heels while serving, bussing, or hosting would violate section 8.22(2.1).

Healthy footwear

Section 8.22(2.1) is not intended to interfere with a worker's choice of footwear where there are no hazards of foot or ankle injury or potential for musculoskeletal injury (such as office or other predominantly sedentary work) as in the third risk category described in OHS Guideline G8.22 Footwear.

In deciding whether certain footwear is appropriate, consideration should be given to factors that promote foot and musculoskeletal health. Questions to ask include: Does the toe box allow for normal foot function and natural toe positioning, or does it squeeze toes together unnaturally? Does this footwear distribute body weight over the whole foot, or does it place more weight on the forefoot? Does the heel make sufficient contact with the walking surface to provide a stable base for good musculoskeletal alignment and balance, or does it detract from them? If the answer to the first part of any of these questions is "no" and the answer to the second part is "yes," that footwear is likely not appropriate for the worker's work.

G8.22(3) Specific safety protective features

Issued August 1, 1999; Editorial Revision April 2005; Revised September 22, 2015

Regulatory excerpt

Section 8.22(3) of the OHS Regulation ("Regulation") states:

If a determination has been made that safety protective footwear is required to have toe protection, metatarsal protection, puncture resistant soles, dielectric protection or any combination of these, the footwear must meet the requirements of:

(a) CSA Standard CAN/CSA-Z195-M92, Protective Footwear,

(b) ANSI Standard Z41-1991, American National Standard for Personal Protection - Protective Footwear,

(c) British Safety Institution Standard BS EN 345:1993 Specification for Safety Footwear for Professional Use, or

(d) British Safety Institution Standard BS EN 346:1993 Specification for Protective Footwear for Professional Use.

Section 8.3(2) of the Regulation states:

If the use of personal protective equipment creates hazards equal to or greater than those its use is intended to prevent, alternative personal protective equipment must be used or other appropriate measures must be taken.

Purpose of guideline

This guideline explains the grades of safety footwear. It also provides guidance on the selection of appropriate footwear for stated hazards.

Grades of safety footwear

The levels of footwear certified by the Canadian Standards Association (CSA) as meeting CAN/CSA Z195-M92 are set out in the following table.

| Grade | 1 | 2 | 3 |

|---|---|---|---|

| Internal CSA label colour denoting only grade of toe protection | Green | Yellow | Red |

| External triangular CSA patch colour denoting sole plate puncture protection with toe protection | Green | Yellow | Red |

| External rectangular patch colour with Greek letter omega (Ω) in orange denoting only electrical shock resistant soles | White | White | White |

| External rectangular patch colour with green "SD" notation and an electrical grounding symbol, denoting static dissipate footwear | Fluorescent Yellow | Fluorescent Yellow | Fluorescent Yellow |

| Protective Toecap Impact Resistance, joules (ft*lb) | 125 (93) | 90 (65) | 60 (45) |

The degree of protection to the toe based on the table above is approximately as follows:

Grade 1 - Dropping a 30 pound weight from 3 feet onto toe

Grade 2 - Dropping a 20 pound weight from 3 feet onto toe

Grade 3 - Dropping a 15 pound weight from 3 feet onto toe

Sole plate puncture protection is only available in CSA certified footwear in combination with toe protection. All sole plates are designed to withstand the same puncture force using a pointed tester, and the colour of the external triangular patch varies only with the grade of toe protection. The external triangular patch may be positioned in any conspicuous location on the right footwear upper. The top of the tongue is an acceptable patch location; provided the patch is visible when the footwear is laced up.

Section 4.4(2)(a) permits the reliance on other standards which are acceptable to WorkSafeBC.

The following American National Standards Institute (ANSI) and British Standards Institution (BSI) Standard Impact and Compression classification combinations are acceptable substitutes for the named CSA Grades:

| CSA Grade | Equivalent ANSI Classifications | Equivalent BSI Designations |

|---|---|---|

| 1 | I/75 combined with C/751 | Safety General, Heavy Duty, or Clog; Safety Footwear with toe impact energy protection levels of either 120 joules, 160 joules, or 200 joules (88, 118, or 148 ft. lb) |

| 2 | I/50 or higher, combined with C/50 or higher2 | Protective Footwear with toe impact energy protection levels of 80 joules (59 ft. lb.) |

| 3 | I/30 or higher, combined with C/30 or higher3 | Protective Footwear with toe impact energy protection levels of 40 joules (30 ft. lb) |

NOTES:

1 This is any of the safety footwear meeting British Standard BS 1870: Part 1:1988, Safety Footwear, Part 1. Specification for safety footwear other than all-rubber and all-plastics moulded types, as amended.

2 This is protective footwear meeting British Standard BS 4972 Specification for Women's Protective Footwear, as amended.

3 This is protective footwear meeting British Standard BS 4972 Specification for Women's Protective Footwear, as amended.

Safety footwear considerations

External strap-on or glue-on "safety toecaps" do not meet any recognized safety standard and should not be used as an alternative to recognized safety footwear. Strap-on toecaps may be used to provide additional protection over the top of CSA Grade 1 safety footwear. Strap-on toecaps are not suitable replacements for integral metatarsal protectors.

Slip-on rubber type footwear with integral safety toecaps, which slip on over existing footwear, and have evidence of independent testing proving that they meet the impact criteria of CSA Standard Z195, may be used.

If a hazard requires metatarsal protectors, the metatarsal protectors should be an integral part of the footwear. (This form of protection is typically required in foundries and heavy manufacturing where steel plate, beams, or rails are handled, but it is not normally required in the construction industry.) Metatarsal protectors that only attach to the laces or are only strapped in place do not meet the CSA Standard Z195 and should not be used because there is no assurance the metatarsal protector is properly supported by the toecap.

There are activities and work environments where, although the dangers of injury to the worker do not require the specific protective footwear meeting the requirements of one of the standards referred to in section 8.22(3), appropriate footwear must be worn to prevent injury to the worker. Section 8.22(2) specifies some of the hazards for which protection may be required, such as slipping, uneven terrain, abrasion, ankle protection, and foot support, temperature extremes, and corrosive substances. The footwear standards, such as the CSA Standard CAN/CSA-Z195-M92, do not provide performance requirements to guide the selection or assessment of footwear for protection from these hazards. The employer must assess each worker's exposure to these dangers and ensure the worker's footwear is of a type and construction that minimizes, as far as is practicable, the risk of injury to the worker. Refer also to OHS Guideline G8.22 Footwear.

In addition to the appropriate approved safety devices for metatarsal, sole penetration and toe protection, the following criteria need to be considered in the selection of "appropriate" footwear:

- If the possibility of ankle cuts or abrasion exists, the footwear should be at least 13 cm (about 5 inches) high and provide adequate protection from cuts and abrasion. (The height of footwear is the measurement from the top of the sole at the arch to the top of the upper.)

- For walking on uneven surfaces, footwear should provide adequate ankle support and be worn tight fitting around the ankle to provide sufficient ankle support. Appropriate footwear would generally be lace-up boots. Cowboy style and rubber boots would not provide sufficient ankle support on uneven surfaces. Lace-up style 20 cm (8 inch) leather-upper winter boots generally provide sufficient ankle support on uneven surfaces.

- Athletic shoes are acceptable for occupational use provided the style and construction provides protection from the hazards to which the worker will be exposed. For example, mesh-type covering over the toe area would not be appropriate in a laboratory where there is danger of chemicals dropping onto the foot. Low cut uppers will not be appropriate if there is danger of abrasion to the ankle.

Guidelines for certain types of workers are as follows:

- A worker in the construction industry, or any other similar working environment where there is risk of toe injury, should wear safety footwear with CSA Grade 1 toe protection.

- A worker in the construction industry, or any other industry with a possibility of sole punctures, should wear footwear with protective sole plates.

- A worker in any industry with a potential for electric shock, for example an electrician or powerline technician, should wear footwear with dielectric protective soles, in addition to any other protective features required by the circumstances of the work.

- A worker using high pressure washing or cutting equipment should wear footwear or footwear cover devices which protect the whole top area of the foot from accidental contact with the washing or cutting stream. Conventional safety toe and metatarsal protectors do not cover a sufficient portion of the worker's foot to protect the foot during this type of work.

- A worker in a warehouse should wear safety footwear with CSA Grade 1 toe protection.

- A worker in a retail store environment using pallet jacks, forklifts, or other rolling equipment should wear footwear with CSA Grade 1 toe protection.

The circumstances at a particular workplace may justify a variation from the above recommendations. For example, an employer may arrange the work in a manner that eliminates all hazards of foot injury.

There are activities and work environments where a heavy work shoe or boot, or a specific protective feature, might normally be required but wearing such footwear could endanger the worker. In this circumstance, section 8.3(2) of the Regulation requires that alternative personal protective equipment be used or that other appropriate measures be taken to adequately control the hazard.

The following measures/practices are generally recognized as being acceptable to WorkSafeBC:

- A carpet layer or similar finishing trade requiring a worker to constantly kneel down will generally not wear safety-toed footwear.

- A worker (steel erector) climbing or walking on steel will generally not wear safety-toed footwear. However, the worker should wear substantial footwear having leather uppers reaching past the ankle.

- A worker in the logging industry walking on logs, steep sidehills, or uneven ground will generally not wear safety-toed footwear, although safety-toed footwear will be necessary when using tools such as axes or chain saws. Note that section 8.23(2) of the Regulation requires "Caulked or other equally effective footwear must be worn by workers who are required to walk on logs, poles, pilings or other round timbers."

In addition to the above, a worker exposed to an environment requiring rubber boots extending above the ankle for protection from chemicals, water or other liquids, is not expected to have tight fitting leather uppers if walking on uneven surfaces.

These exceptions apply while the worker is performing the particular job function. When the worker is performing other job functions or walking through surrounding hazards, the worker must wear footwear appropriate to the hazard.

G8.22(3)-1 Footwear – Alternate standards

Issued September 28, 2007; Revised June 14, 2013; Editorial Revision June 3, 2019

Regulatory excerpt

Section 8.22 of the OHS Regulation ("Regulation") states in part:

(1) A worker's footwear must be of a design, construction, and material appropriate to the protection required.

(2) To determine appropriate protection under subsection (1) the following factors must be considered: slipping, uneven terrain, abrasion, ankle protection and foot support, crushing potential, temperature extremes, corrosive substances, puncture hazards, electrical shock and any other recognizable hazard.

(3) If a determination has been made that safety protective footwear is required to have toe protection, metatarsal protection, puncture resistant soles, dielectric protection or any combination of these, the footwear must meet the requirements of:

(a) CSA Standard CAN/CSA-Z195-M92, Protective Footwear,

(b) ANSI Standard Z41-1991, American National Standard for Personal Protection - Protective Footwear,

(c) British Safety Institution Standard BS EN 345:1993 Specification for Safety Footwear for Professional Use, or

(d) British Safety Institution Standard BS EN 346:1993 Specification for Protective Footwear for Professional Use.