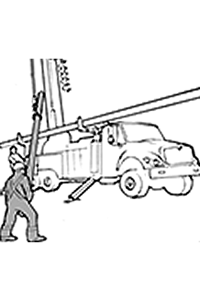

Worker struck as utility pole was lifted onto truck

Date of incident: December 2012

Notice of incident number: 2012110210263

Employer: Power pole installation and service company

Incident summary

In the works yard, two workers were loading two wooden utility poles onto a digger derrick (a truck that installs utility poles). The rigger was assisting the operator by placing tongs around each pole and navigating the poles into the pole bunk. The workers lifted the first pole onto the digger derrick. The second pole was not level as it was lifted, and the rigger was manually holding the tapered end to navigate the pole into place. The pole hit the bunk stake and shook violently. The tongs released the pole, which then struck the rigger, causing serious injuries.

Cause

- Worker hit by utility pole during loading: The utility pole was not under control while being lifted onto the digger derrick. One end of the pole struck the pole bunk stake, and the pole was released from the timber tongs. The falling pole hit the rigger, who was within range of the falling pole.

- Tongs were inappropriately used for lifting: Timber tongs were being used to quickly load two utility poles into the pole bunk of the digger derrick. The timber tongs did not fit properly onto the lifting hook of the digger derrick, and they were misplaced on the utility pole, resulting in an uneven lift. Instead, a chain sling would have provided more load security during the lifting phase.

- Tag line not used: The rigger should have used a tag line to manoeuvre the pole during the lift. Instead, he physically handled the pole, which put him in close proximity to the load during the lift and within striking range of the pole when it fell.

- Lack of training: The employer did not have a prescriptive and consistent training process with respect to safely loading poles on a digger derrick. The workers were not given proper training as to what their duties and responsibilities were for safely loading poles, which below-the-hook lifting device must be used, and what their duties were for ensuring worker safety when loading poles.

- Lack of hazard assessment and safe work procedure: No hazard assessment was done for loading utility poles; thus, no written safe work procedure was created. The employer did not conduct a hazard assessment to identify hazards and risks and determine how the installation of the pole bunks would affect the mechanics of the boom operations.

- Inadequate supervision: The new worker and the young worker were not adequately supervised during the absence of their direct supervisor. Other means were available to ensure that adequate supervision occurred; however, no actions were taken to ensure the workers were adequately supervised.

2021-04-22 20:42:33