Worker injured by explosion in hose during pressure testing

Date of incident: March 2014

Notice of incident number: 2014155400035

Employer: Heavy equipment manufacturer

Incident summary

Two workers were bending aluminum tubing as they assembled a decanting post, a metal pipe structure used to decant liquid natural gas from tanks. Another worker was pressure testing a nearby decanting post to identify leaks. An explosion occurred in a hose attached to the decanting post that was being pressure tested. The hose, which had a large metal fitting attached to its end, whipped around the work area and struck a worker in the chest, causing serious injuries.

Investigation conclusions

Cause

- Adiabatic compression explosion: When a gas is compressed in an isolated system (a confined area) without heat transfer, the pressure of the gas increases and its temperature rises. This is known as adiabatic compression. In this incident, the decanting system with the hoses installed and capped with quick-connect caps was an isolated system. The use of high-pressure air in combination with a rapid increase in pressure created an adiabatic compression explosion. This explosion caused the hose to whip around and strike a worker, causing serious injuries.

Underlying factors

- No effective safe work procedures: The pressure test in this case was being performed by the lead hand, and two other personnel were working just a few feet away. The employer's written procedures required the worker performing the test to remain in the area but for all other workers to be removed. However, these procedures were not effective because they required the lead hand to work in an area with a risk of explosion.

- Improper selection of air as a test medium: Air should not have been used as a test medium in the decanting post's system to detect leaks for the following reasons:

- Air contains oxygen, which is an element needed for combustion.

- Oxygen is a gaseous substance and expands rapidly. Therefore, when an explosion occurs during testing, the expansion of the gaseous substance greatly exacerbates the potential for harm. Another medium such as water, which is widely used for pressure testing, would not behave in the same manner.

- Heat, another element needed for combustion, is generated when air is compressed rapidly.

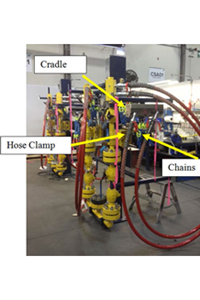

- Ineffective hose restraint methods: The decanting hoses were restrained by hose clamps, chains, and a cradle. These efforts to restrain the hoses failed when the explosion happened. The hose clamp failed to restrain the hose, and it whipped around the work area.

- Ineffective supervision: Failure of the lead hand to safely supervise the workers in the immediate test area and remove them from a potentially hazardous situation was an underlying factor in this incident.

- Failure to perform a comprehensive risk assessment: A comprehensive risk assessment should have been performed because the double-leg decanting posts were the first of their kind to be built at the facility. Also, testing with air is extremely dangerous due to its expansion properties. The employer should have conducted a comprehensive risk assessment to identify various effective means to protect workers from the possible explosion hazard. The failure of the company engineers to recognize the hazard posed by pressure testing with air and to implement the proper safety controls was an underlying factor in this incident.

2021-04-22 20:42:33