Contents

DEFINITIONS, DESIGNATION AS HAZARDOUS SUBSTANCES, AND GENERAL INFORMATION REQUIREMENT

G5.1.1 Designation of biological agents as hazardous substances

WORKPLACE HAZARDOUS MATERIALS INFORMATION SYSTEM (WHMIS)

G5.3-1 WHMIS application

G5.3-2 Fire extinguishers

G5.3-3 Cylinders of breathing air

G5.3-4 Exemptions

G5.3-5 Leaded surface coating materials

G5.3-6 "For industrial use only" labels

G5.3-7 Warehousing of hazardous products

G5.3-8 The application of WHMIS in agriculture

G5.5 WHMIS program – Consultation on WHMIS education and training

G5.6 Worker education and training

G5.8-1 Supplier label [Retired]

G5.8-2 Supplier label: Labelling on leased or rented chemical application units

G5.8-3 Laboratory sample shipments containing at least two different hazardous products

G5.14-1 Supplier safety data sheet (SDS) [Retired]

G5.14-2 Fees

G5.15 Laboratory SDS

CONTAINERS AND STORAGE

G5.22 Covers

G5.25 Storage practices

FLAMMABLE AND COMBUSTIBLE SUBSTANCES

G5.27 Ignition sources – Combustible liquid normally used as fuel

G5.27(2) Electrical Safety Act repealed [Retired]

G5.28 Bonding or grounding of containers – Ensuring effectiveness

G5.30 Dispensing [Retired]

G5.32 Manual cleaning – Work procedures

SUBSTANCES UNDER PRESSURE

G5.38 Handling and securing cylinders

CONTROLLING EXPOSURE

Table of Exposure Limits for Chemical and Biological Substances

G5.48-1 Table of exposure limits – Background information [Retired]

G5.48-2 Exposure limits and the review process

G5.48-3 Normal 8-hour work period

G5.48-4 Conversions for ppm and mg/m3

G5.48-5 Welding fumes

G5.48-6 Allergenic species of wood dust

G5.48-7 Nuisance dusts

G5.48-8 Simple asphyxiants – Inert gases or vapours

G5.48-9 Measuring compliance with the exposure limits

G5.48-10 Use of indicator tubes to measure compliance

G5.48-11 Sampling of thoracic fraction of sulfuric acid mist [Retired]

G5.48-12 Establishing exposure limits for certain refined hydrocarbon mixtures

G5.48-13 Monitoring worker exposure to sulfur dioxide [Retired]

G5.49 Application of excursion limits

G5.50 Extended work periods

G5.51 Additive effects

G5.52 Skin notation

G5.53-1 Workplace monitoring

G5.53-2 Assessing compliance – The walkthrough survey

G5.53-3 Monitoring worker exposure

G5.53-4 Occupational hygiene methods acceptable to WorkSafeBC

G5.54-1 Exposure control plan

G5.54-2 Elements of an exposure control plan

G5.54-3 Risk identification, assessment, and control

G5.54-4 Hygiene facilities and decontamination procedures

G5.54-5 Health monitoring

G5.54-6 Documentation

G5.54-7 Drywall sanding requirements

G5.55 Type of controls

G5.56 Oxygen deficiency

G5.57 Designated substances

G5.58 Protective policy

G5.59 Investigating symptoms

Table of Exposure Limits for Chemical and Biological Substances

VENTILATION

G5.62 Submitting plans

G5.63 Building modification

G5.70 Discharged air

G5.71(3) Location and construction of dust collectors

INTERNAL COMBUSTION ENGINES

G5.73 Engine servicing and work area assessment for mobile equipment operated indoors

G5.75 Mobile equipment emission controls

HAZARDOUS WASTES AND EMISSIONS

G5.80 Hazardous wastes and emissions – Sharp-edged waste

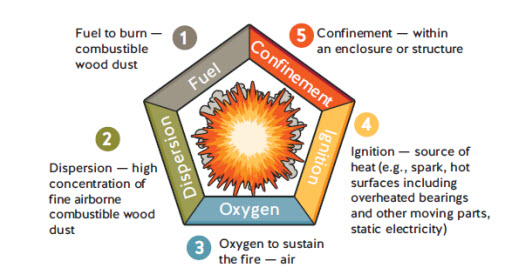

G5.81 Combustible dust - Sawmills and other wood products manufacturing facilities

PERSONAL HYGIENE

G5.82 Employer's responsibility

G5.83 Worker's responsibility

EMERGENCY WASHING FACILITIES

G5.85 Where required

G5.86 Water supply

G5.88 Risk assessment

G5.89 Table 5-3: Provision and location of emergency washing equipment

G5.90 Mobile shower units

G5.91 Remote worksites

G5.93 Testing and maintenance

G5.94 Training

G5.95 Protection from freezing

EMERGENCY PROCEDURES

G5.97 Emergency procedures — emergency plan

G5.99 Risk assessment

G5.101 Procedures for spill cleanup and re-entry

Guidelines - Part 5 - Definitions, Designation as Hazardous Substances, and General Information Requirement

G5.1.1 Designation of biological agents as hazardous substances

Issued February 1, 2008; Editorial Revision to include February 1, 2011 regulatory amendment

Regulatory excerpt

Section 5.1.1 of the OHS Regulation ("Regulation") states:

For the purposes of sections 5.2 and 6.33 to 6.40 and Part 30, the following biological agents are designated as hazardous substances:

(a) a liquid or solid material that is contaminated with a prion, virus, bacterium, fungus or other biological agent that has a classification given by the Public Health Agency of Canada as a Risk Group 2, 3 or 4 human pathogen that causes an adverse health effect;

(b) a biological toxin that causes an adverse health effect.

Purpose of guideline

This guideline provides information on Risk Groups 2, 3, and 4 human pathogens that cause adverse health effects.

Risk Groups

Risk Groups 2, 3, and 4 are a component of a universally agreed to classification system as adopted by the Public Health Agency of Canada. This system is based on the biosafety containment classification system of the Public Health Agency of Canada.

The following provides an overview of each Risk Group.

Risk Group 2: A pathogen that can cause human or animal disease but under normal circumstances is unlikely to be a serious hazard to healthy laboratory workers, the community, livestock, or the environment. Laboratory exposures rarely cause infection leading to serious disease; effective treatment and preventive measures are available and the risk of spread is limited. They are considered to represent a moderate risk to individuals and a limited risk to the community. Examples of Risk Group 2 pathogens include the Hepatitis B and Hepatitis C viruses, salmonella, and E. coli bacteria.

Risk Group 3: A pathogen that usually causes serious human or animal disease, or which can result in serious economic consequences but does not ordinarily spread by casual contact from one individual to another, or that can be treated by antimicrobial or antiparasitic agents. They are considered to represent a high risk to individuals but a low risk to the community. Examples of Risk Group 3 pathogens include the human immunodeficiency virus (HIV), and the pathogens causing Creutzfeldt-Jacob disease, hantavirus, and tuberculosis.

Risk Group 4: A pathogen that usually produces very serious human or animal disease, often untreatable, and may be readily transmitted from one individual to another, or from animal to human or vice-versa directly or indirectly, or by casual contact. They are considered to represent a high risk to both the individual and the community. Examples of Risk Group 4 pathogens are the hemorrhagic fever viruses such as Ebola, Marburg, and Lassa fever.

Guidelines - Part 5 - Workplace Hazardous Materials Information System (WHMIS)

G5.3-1 WHMIS application

Issued August 1999; Editorial Revision January 2005; Editorial Revision May 9, 2014; Editorial Revision consequential to February 1, 2015 Regulatory Amendment; Editorial Revision consequential to August 4, 2015 Regulatory Amendment

Regulatory excerpt

Section 1.1(1) of the OHS Regulation ("Regulation") states, in part:

(1) In this Occupational Health and Safety Regulation

"hazardous product" means any product, mixture, material or substance that is classified in accordance with the regulations made under section 15 (1) of the Hazardous Products Act (Canada) in a category or subcategory of a hazard class listed in Schedule 2 of that Act;

Section 5.3 of the Regulation states:

(1) Subject to subsections (2) to (4), sections 5.4 to 5.18 (the WHMIS Requirements) apply to employers and workers with respect to hazardous products used, stored or handled at a workplace.

(2) The provisions concerning a supplier label and SDS do not apply if the hazardous product is

(a) an explosive as defined in section 2 of the Explosives Act (Canada),

(b) a drug, food or cosmetic device within the meaning of the Food and Drugs Act (Canada),

(c) a pest control product as defined in section 2(1) of the Pest Control Products Act (Canada),

(d) a nuclear substance as defined in section 2 of the Nuclear Safety and Control Act (Canada), that is radioactive, or

(e) a consumer product as defined in section 2 of the Canada Consumer Product Safety Act.

(3) The provisions do not apply if the hazardous product is

(a) wood or a product made of wood,

(b) tobacco or a tobacco product as defined in section 2 of the Tobacco Act (Canada),

(c) a manufactured article, or

(d) being transported or handled pursuant to the requirements of the Transportation of Dangerous Goods Act, 1992 (Canada) or the Transport of Dangerous Goods Act.

(4) The provisions do not apply to a hazardous waste, except that the employer must ensure the safe storage and handling of a hazardous waste generated at the workplace through the combination of worker training and the information required by this Regulation.

Purpose of guideline

The purpose of this guideline is to clarify the meaning of "hazardous product."

Hazardous products

A hazardous product is defined in section 1.1(1) of the Regulation as any product, mixture, material, or substance listed in Schedule 2 of the federal Hazardous Products Act. Schedule 2 sets out the following classes of hazardous products:

Physical Hazard Classes

- Explosives

- Flammable gases

- Flammable aerosols

- Oxidizing gases

- Gases under pressure

- Flammable liquids

- Flammable solids

- Self-reactive substances and mixtures

- Pyrophoric liquids

- Pyrophoric solids

- Self-heating substances and mixtures

- Substances and mixtures which, in contact with water, emit flammable gases

- Oxidizing liquids

- Oxidizing solids

- Organic peroxides

- Corrosive to metals

- Combustible dusts

- Simple asphyxiants

- Pyrophoric gases

- Physical hazards not otherwise classified

Health Hazard Classes

- Acute toxicity

- Skin corrosion/irritation

- Serious eye damage/eye irritation

- Respiratory or skin sensitization

- Germ cell mutagenicity

- Carcinogenicity

- Reproductive toxicity

- Specific target organ toxicity — single exposure

- Specific target organ toxicity — repeated exposure

- Aspiration hazard

- Biohazardous infectious materials

- Health hazards not otherwise classified

The contents of these classes are set out in Parts 7 and 8 of the federal Hazardous Products Regulations.

G5.3-2 Fire extinguishers

Issued August 1999; Editorial Revision May 9, 2014; Editorial Revision consequential to August 4, 2015 Regulatory Amendment

Regulatory excerpt

Section 5.8(1) of the OHS Regulation ("Regulation") states:

Subject to any exemptions from labelling requirements in the Hazardous Products Regulations and this Part, an employer must ensure that a hazardous product or the container of a hazardous product received at a workplace is attached or printed with a supplier label.

Section 5.14(1) of the Regulation states:

Subject to subsection (6), an employer who acquires a hazardous product for use, handling or storage at a workplace must obtain a supplier SDS in respect of that hazardous product that complies with the requirements of the Hazardous Products Regulations.

Purpose of guideline

The purpose of this guideline is to clarify the requirements for labelling and safety data sheets (SDS) with respect to fire extinguishers.

Fire extinguishers

Any fire extinguisher pressurized to more than 200 kPa (1.97 atmospheres or 29 psi at 20°C) meets the criteria for inclusion in Workplace Hazardous Materials Information System (WHMIS) Class Gases under Pressure, pursuant to Part 7 Subpart 5 of the federal Hazardous Products Regulations. Some retardants (or performance additives to prevent effects such as freezing or corrosion) may meet criteria for inclusion in WHMIS Class Acute Toxicity established by Part 8 Subpart 1 of the Hazardous Products Regulations. Older soda-acid extinguishers are included as WHMIS Classes, Skin Corrosive/Irritation and Serious Eye Damage/Irritation under Part 8 Subparts 2 and 3 of the Hazardous Products Regulations.

Section 13(1)(b) of the federal Hazardous Products Act (HPA) requires that a supplier apply a label to a hazardous product intended for use in a workplace, or to the container in which the hazardous product is packaged. The label must disclose the required information and display applicable hazard symbols.

A fire extinguisher is not exempted as a manufactured article under section 5.3(3)(c) of the Regulation (section 12(i) of the HPA) because workers are exposed to the hazard of a pressurized container or other hazardous products under normal conditions of use.

Where a fire extinguisher is intended for use in the workplace and is included as a WHMIS hazardous product the following must occur:

- Suppliers who sell extinguishers intended for use in the workplace must apply a WHMIS supplier label to the extinguisher and provide an SDS.

- A firm which recharges a fire extinguisher for an employer must apply a WHMIS supplier label to the extinguisher and provide an SDS, if these are not already applied and provided. Where an employer recharges extinguishers "in-house," a workplace label will suffice if a supplier label is not already on the extinguisher.

- A detachable pressurized cartridge used to pressurize a dry chemical extinguisher must be provided with a WHMIS label in addition to the label on the extinguisher unless the cartridge is immediately installed on the extinguisher after the cartridge is pressurized. Suppliers who pressurize such cartridges must provide a supplier label; employers who pressurize their own cartridges must provide, at minimum, a workplace label. Labels must be applied to individual cartridges unless an alternative acceptable arrangement is used. An example of an acceptable alternative is to provide a WHMIS label on the container of individual cartridges as long as cartridges are immediately installed on the extinguisher after being removed from the container. Where a supplier and employer wish to adopt this alternative or any arrangement in which the employer undertakes to apply supplier labels to cartridges contained in an outer container, the employer should establish the arrangement in writing.

- A generic SDS covering both the cartridge and the extinguisher will be considered acceptable for the purposes of providing an SDS on the cartridge.

G5.3-3 Cylinders of breathing air

Issued August 1999; Editorial Revision May 9, 2014; Editorial Revision consequential to August 4, 2015 Regulatory Amendment; Editorial Revision consequential to August 22, 2022 Regulatory Amendment

Regulatory excerpt

Section 5.7(1)(a) of the OHS Regulation ("Regulation") states:

(1) An employer must ensure that a worker who works with a hazardous product or may be exposed to a hazardous product in the course of the worker's work activities is trained in the following:

(a) the content required on a supplier label and workplace label, and the purpose and significance of the information contained on those labels;

Section 5.8(1) of the Regulation states:

Subject to any exemptions from labelling requirements in the Hazardous Products Regulations and this Part, an employer must ensure that a hazardous product or the container of a hazardous product received at a workplace is attached or printed with a supplier label.

Section 5.8(3) of the Regulation states:

Subject to any exemptions from labelling requirements in the Hazardous Products Regulations and this Part, an employer must replace the label with either a supplier label or a workplace label if a supplier label applied to a hazardous product or a container of a hazardous product becomes illegible or is accidentally removed from the hazardous product or the container.

Section 5.14(1) of the Regulation states:

Subject to subsection (6), an employer who acquires a hazardous product for use, handling or storage at a workplace must obtain a supplier SDS in respect of that hazardous product that complies with the requirements of the Hazardous Products Regulations.

Purpose of guideline

The purpose of this guideline is to clarify the requirements for providing labels, safety data sheets (SDS), and worker training specific to compressed gas cylinders of breathing air.

Compressed air cylinders

Compressed air cylinders used in self-contained breathing apparatus (SCBA) are included as WHMIS Class Gases under Pressure pursuant to Part 7 Subpart 5 of the federal Hazardous Products Regulations.

Provincial requirements for cylinders filled in-house

- Safety Data Sheets: An SDS must be provided for synthetic mixtures of breathing gases. An SDS is not required for cylinders of compressed respirable atmospheric air as this air must meet the air quality required by section 8.37 of the Regulation.

- Labels: Workplace labels specifying the product identity and making reference to the SDS are required on synthetic mixtures of breathing gases. Safe handling instructions must be provided through the worker education and training program. For cylinders of respirable atmospheric air which are identifiable to workers by size and shape, for which an SDS is not required, and where worker instruction in the safe use of the SCBA is in place as required by part 8 of the Regulation, further labelling or means of identification is not necessary.

Federal requirements for pressurized cylinders sold, imported, or filled on contract

- Suppliers who provide cylinders with compressed synthetic mixtures for breathing purposes for use in a workplace must apply supplier labels and provide an SDS

- Suppliers who provide cylinders of breathing air for use in the workplace are not required to provide an SDS or a reference to the SDS on the supplier label provided the supplier label meets the following:

- Includes the following six elements of a WHMIS supplier label: the product identifier, supplier identifier, hazard pictogram, signal word, hazard statement, and precautionary statements (which include first aid measures)

- Includes a precautionary statement advising users to ensure the cylinder is filled with air meeting the quality standards of the local regulatory agency

Where cylinders are refilled by an outside contractor who is not the original supplier of the cylinder, the contractor must provide a supplier identifier. If the original supplier label becomes illegible or is accidentally removed from the hazardous product, the supplier must provide a supplier label.

G5.3-4 Exemptions

Issued August 1999; Editorial Revision May 9, 2014; Editorial Revision consequential to August 4, 2015 Regulatory Amendment

Regulatory excerpt

Section 5.3 of the OHS Regulation ("Regulation") states:

(1) Subject to subsections (2) to (4), sections 5.4 to 5.18 (the WHMIS Requirements) apply to employers and workers with respect to hazardous products used, stored or handled at a workplace.

(2) The provisions concerning a supplier label and SDS do not apply if the hazardous product is

(a) an explosive as defined in section 2 of the Explosives Act (Canada),

(b) a drug, food or cosmetic device within the meaning of the Food and Drugs Act (Canada),

(c) a pest control product as defined in section 2(1)of the Pest Control Products Act (Canada),

(d) a nuclear substance as defined in section 2 of the Nuclear Safety and Control Act (Canada), that is radioactive, or

(e) a consumer product as defined in section 2 of the Canada Consumer Product Safety Act.

(3) The provisions do not apply if the hazardous product is

(a) wood or a product made of wood,

(b) tobacco or a tobacco product as defined in section 2 of the Tobacco Act (Canada),

(c) a manufactured article, or

(d) being transported or handled pursuant to the requirements of the Transportation of Dangerous Goods Act, 1992 (Canada) or the Transport of Dangerous Goods Act.

(4) The provisions do not apply to a hazardous waste, except that the employer must ensure the safe storage and handling of a hazardous waste generated at the workplace through the combination of worker training and the information required by this Regulation.

Purpose of guideline

The purpose of this guideline is to clarify requirements for information, education, training, labelling, and safety data sheets (SDS) for hazardous products that are partially or completely exempted from Workplace Hazardous Material Information System (WHMIS).

Hazardous products exempt from WHMIS legislation

Where a hazardous product is used or produced in a workplace, workers must know the hazard, how to protect themselves in normal work and in emergency situations, and where to find more information when it is needed. This is required regardless of whether the hazardous product is included fully in the WHMIS program or is partially or completely exempted. The information required for partially and completely exempted hazardous products and wastes include hazards (e.g., toxicity, fire, explosion, or reactivity), storage information, safe work procedures, protective equipment, spill, leakage, firefighting information, and first aid measures.

Partial exemptions

Partially exempt hazardous products, specified in section 5.3(2) of the Regulation and labelled under federal legislation other than WHMIS, can be sold without a WHMIS label or SDS. When these hazardous products are used in the workplace, sections 5.6 and 5.7 of the Regulation require worker education and training. Workplace labels must be applied if the hazardous product is not in the original container.

Complete exemptions

Hazardous products specified in section 5.3(3) of the Regulation are excluded from both federal and provincial WHMIS requirements. General occupational health and safety requirements governing workplace education and training, as well as the general information requirement set out in section 5.2 of the Regulation must be met. The provision of an SDS by suppliers will assist employers in meeting their obligations under these sections.

Hazardous wastes

An employer must provide worker training and information sufficient to ensure the safe storage and handling of a hazardous waste generated at the workplace, pursuant to section 5.3(4) of the Regulation. Information from an SDS for waste components or precursors, combined with the employer's firsthand knowledge about the process which generated the hazardous waste, will form the basis of the information given to employees.

G5.3-5 Leaded surface coating materials

Revised April 9, 2009; Editorial Revision March 7, 2011; Editorial Revision consequential to August 4, 2015 Regulatory Amendment

Regulatory excerpt

Section 5.3(2)(e) of the OHS Regulation ("Regulation") states:

(2) The provisions concerning a supplier label and SDS do not apply if the hazardous product is

(e) a consumer product as defined in section 2 of the Canada Consumer Product Safety Act.

Purpose of guideline

The purpose of this guideline is to highlight the federal requirements applicable to leaded surface coating materials.

Health Canada requirements

The federal Surface Coating Materials Regulations ("SCMR") prohibits the advertising, sale, and importation of surface coating materials containing a lead concentration exceeding 90 mg/kg (0.009% w/w). Surface coating materials that are used for any of the applications listed in section 4(2) of the SCMR exempt from this restriction, but specific labelling requirements apply if their lead content does exceed 0.009% w/w. These regulatory requirements are enforced by Health Canada.

G5.3-6 "For industrial use only" labels

Issued August 1999; Editorial Revision May 9, 2014; Editorial Revision consequential to August 4, 2015 Regulatory Amendment

Regulatory excerpt

Section 5.3(2) of the OHS Regulation ("Regulation") states:

The provisions concerning a supplier label and SDS do not apply if the hazardous product is

(a) an explosive as defined in section 2 of the Explosives Act (Canada),

(b) a drug, food or cosmetic device within the meaning of the Food and Drugs Act (Canada),

(c) a pest control product as defined in section 2 (1) of the Pest Control Products Act (Canada),

(d) a nuclear substance as defined in section 2 of the Nuclear Safety and Control Act (Canada), that is radioactive, or

(e) a consumer product as defined in section 2 of the Canada Consumer Product Safety Act.

Purpose of guideline

The purpose of this guideline is to clarify WorkSafeBC's interpretation of product labelling that specifies industrial or professional use of hazardous products labelled "for industrial use only."

Industrial use

Statements on the label of a hazardous product which identify a product for industrial use imply intent for product use in the workplace. This includes statements such as "for industrial use only" or "for professional use only." Where the product is a hazardous product as defined in section 1.1(1) of the Regulation, the Workplace Hazardous Materials Information System (WHMIS) requirements apply.

G5.3-7 Warehousing of hazardous products

Issued February 27, 2001; Revised September 21, 2012; Editorial Revision consequential to August 4, 2015 Regulatory Amendment

Regulatory excerpt

Section 5.3 of the OHS Regulation ("Regulation") states:

(1) Subject to subsections (2) to (4), sections 5.4 to 5.18 (the WHMIS Requirements) apply to employers and workers with respect to hazardous products used, stored or handled at a workplace.

(2) The provisions concerning a supplier label and SDS do not apply if the hazardous product is

(a) an explosive as defined in section 2 of the Explosives Act (Canada),

(b) a drug, food or cosmetic device within the meaning of the Food and Drugs Act (Canada),

(c) a pest control product defined in section 2(1) of the Pest Control Products Act (Canada),

(d) a nuclear substance as defined in section 2 of the Nuclear Safety and Control Act (Canada), that is radioactive, or

(e) a consumer product as defined in section 2 of the Canada Consumer Product Safety Act.

(3) The provisions do not apply if the hazardous product is

(a) wood or a product made of wood,

(b) tobacco or a tobacco product as defined in section 2 of the Tobacco Act (Canada),

(c) a manufactured article, or

(d) being transported or handled pursuant to the requirements of the Transportation of Dangerous Goods Act, 1992 (Canada) or the Transport of Dangerous Goods Act.

(4) The provisions do not apply to a hazardous waste, except that the employer must ensure the safe storage and handling of a hazardous waste generated at the workplace through the combination of worker training and the information required by this Regulation.

Purpose of guideline

The purpose of this guideline is to clarify the application of the WHMIS requirements in the Regulation relative to federal requirements when a hazardous product is "handled" in a warehouse.

Application of WHMIS requirements

Section 5.3(3)(d) of the Regulation states, in part, that the WHMIS requirements "do not apply if the hazardous product is being transported or handled pursuant to the requirements of the Transportation of Dangerous Goods Act, 1992 (Canada) or the Transport of Dangerous Goods Act."

The Transportation of Dangerous Goods (TDG) Act defines handling as "loading, unloading, packing or unpacking dangerous goods in a means of containment for the purposes of, in the course of or following transportation and includes storing them in the course of transportation." Handling in this context does not include actual use of a hazardous product. TDG requirements deal primarily with acute exposures and the use of symbol alerts and placards. Transportation workers should not be exposed to hazards associated with the hazardous product unless there is an emergency, short-term circumstance such as a transport vehicle accident and spill. Conversely, worker exposure to hazardous products in a workplace can occur in a wider variety of circumstances and over a longer period of time. Hence, WHMIS requirements are more extensive than TDG and include the use of explicit labels and safety data sheets (SDS).

Application of WHMIS or TDG depends on the flow of goods through commerce as outlined in the following flow chart. WHMIS requirements are meant to apply at points of sale or use rather than during shipment. Transportation generally means to and from workplaces.

WHMIS, both federal (labels and SDS) and provincial (education and training, workplace labels), applies where hazardous products are used, processed, or repackaged in a warehouse. When warehoused, hazardous products can be:

- In "transshipment" (held in temporary storage between points of shipment)

- Repackaged (assembled, packaged, labelled, or relabelled)

- Used

Sections 5.2(c) and 5.2(d) of the Regulation are non-WHMIS "general information requirements" that apply to a transshipment warehouse where in the case of an emergency or spill of a hazardous product, an emergency response system must be established. This emergency response system requires written emergency and spill cleanup procedures, and effective supervisor and worker training in these procedures.

A hazardous product that is repackaged or used is subject to the WHMIS section of the Regulation since workers may be exposed to the hazards of the product.

The following table sets out the legislation and resources that apply to hazardous products in a warehouse:

| Federal | Provincial - Regulation | Other | |

|---|---|---|---|

| Transshipment | TDG | Non-WHMIS sections [5.2(c) & 5.2(d)] |

CANUTEC* |

| Repackaging | HPA/HPR** | WHMIS sections (5.3 – 5.18) |

|

| Used | HPA/HPR | WHMIS sections (5.3 – 5.18) |

Notes to table:

* CANUTEC (Canadian Transport Emergency Centre), part of the TDG Directorate, Transport Canada, provides hazard information in case of transport-related emergency situations. Phone: (613) 996-6666.

** HPA/HPR (Hazardous Products Act/Hazardous Products Regulations)

G5.3-8 The application of WHMIS in agriculture

Issued January 1, 2005; Editorial Revision May 9, 2014; Editorial Revision consequential to August 4, 2015 Regulatory Amendment

Regulatory excerpt

Section 5.3(1) of the OHS Regulation ("Regulation") states:

Subject to subsections (2) to (4), sections 5.4 to 5.18 (the WHMIS Requirements) apply to employers and workers with respect to hazardous products used, stored or handled at a workplace.

Purpose of guideline

The purpose of this guideline is to provide information to farmers, ranchers, and agriculture workers on the general framework of the Workplace Hazardous Materials Information System (WHMIS), the application of regulatory requirements to partially and completely exempt products, and the means of forwarding concerns to WorkSafeBC about products for which suppliers are not providing information meeting WHMIS requirements.

Application to suppliers and workplaces

WHMIS was developed in 1988 as a major step in helping to ensure that employers and workers would be provided with information on the hazards and control measures for hazardous materials (termed "hazardous products") in the workplace. The requirements were made applicable to agriculture in 1993.

Broadly speaking, WHMIS applies on the following two levels:

- Suppliers: The suppliers of hazardous products are required, under federal legislation, to provide information to employers for hazardous products used in the workplace. Typically, the information must be provided in two ways: container labels, and safety data sheets (SDS).

- Workplace: Employers are required, under provincial legislation, to ensure hazardous products received in the workplace have the necessary labels and SDS, and to ensure that workers are educated and trained in the safe use of the products. Other obligations apply. For example, if a hazardous product is transferred from the supplier container to another container in the workplace it is necessary to label or identify the workplace container. Sections 5.3 to 5.18 of the Regulation cover the provincial WHMIS requirements.

Partially and completely exempt products

As shown in section 5.3 of the Regulation, there are different degrees to which hazardous products are covered by WHMIS.

Many industrial products are fully covered by WHMIS, meaning the supplier requirements for labels and SDS apply, and the employer must ensure that workplace obligations under WHMIS are also met. Examples of such hazardous products in agriculture include compressed gas cylinders used in welding operations, fuel products on site, and some acids and caustics.

Some hazardous products are partially exempt. Examples include pesticides and drugs (including some sterilants and disinfectants). In these cases there is no federal requirement for WHMIS labels and SDS, but typically the hazardous products must meet other federal labelling and information requirements specific to them. In the case of pesticides and some other partially exempt products, suppliers will often provide an SDS, and the buyer should obtain an SDS wherever available. The employer must meet provincial WHMIS requirements for information, education, and training of workers and other matters such as workplace labels, as covered in sections 5.3-5.18 of the Regulation. Refer to OHS Guideline G5.3-4 for more information on partially exempt hazardous products.

Also, note that section 6.75 of the Regulation requires that employers make readily available to workers an SDS or its written equivalent for pesticides used at the workplace. Obtaining an SDS from the pesticide supplier will help ensure that the requirement is met. An SDS compliant with WHMIS will include information on the following categories:

- Identification

- Hazard identification

- Composition/information on ingredients

- Firstaid measures

- Firefighting measures

- Accidental release measures

- Handling and storage

- Exposure controls/personal protection

- Physical and chemical properties

- Stability and reactivity

- Toxicological information

- Ecological information

- Disposal considerations

- Transport information

- Regulatory information

- Other information

If the pesticide SDS does not fully meet WHMIS standards, but has sufficient information to ensure the health and safety of workers using, transporting, or storing the hazardous product, the SDS may be considered acceptable. Refer to OHS Guideline G6.75 for a list of the information that would be considered equivalent.

Some hazardous products such as welding rods, which are manufactured articles, are completely exempt from both the federal and provincial WHMIS requirements. In such cases, where the article contains a hazardous material, the employer is encouraged to obtain an SDS if available. Section 5.2 of the Regulation addresses general information requirements for any chemical or biological substance that could cause an adverse health effect; which would apply in this case. Section 5.2 covers general responsibilities to identify the hazards of the substance, educate the worker, and implement and follow safe work procedures. Refer to OHS Guideline G5.3-4 for more information on completely exempt products.

What if a supplier is not providing adequate labels or SDS where required by WHMIS?

Where an agricultural workplace is unable to get the proper WHMIS information for a hazardous product from the supplier or distributor, the farmer or rancher is encouraged to contact WorkSafeBC at (604) 276-3100 (long distance toll free at 1-888-621-7233), or the nearest WorkSafeBC Regional Office. Many of WorkSafeBC's occupational hygiene officers are designated to enforce federal WHMIS requirements on suppliers and distributors in this province. Where a distributor is providing product from elsewhere in Canada, WorkSafeBC will forward the concern to the responsible jurisdiction for its follow-up with the supplier. For more information on the application of WHMIS, refer to the WorkSafeBC publication, WHMIS at Work, which is available on the WorkSafeBC website at www.worksafebc.com.

G5.5 WHMIS program — Consultation on WHMIS education and training

Issued August 1999; Editorial Revision May 9, 2014; Editorial Revision consequential to August 4, 2015 Regulatory Amendment

Regulatory excerpt

Section 5.5 of the OHS Regulation ("Regulation") states:

If hazardous products are used in the workplace the employer, in consultation with the joint committee or health and safety representative as applicable, must establish and maintain an effective WHMIS program, as part of the overall workplace health and safety program, which

(a) addresses applicable WHMIS Requirements including education and training,

(b) is reviewed at least annually, or more frequently if required by a change in work conditions or available hazard information, and

(c) provides for the periodic evaluation of the knowledge of workers using suitable means such as written tests and practical demonstrations.

Purpose of guideline

The purpose of this guideline is to clarify the meaning of the phrase "in consultation with the joint committee or health and safety representative," as it applies to the development and implementation of Workplace Hazardous Materials Information System (WHMIS) education and training.

Consultation

An employer has consulted with the joint committee or health and safety representative regarding WHMIS education and training if the following two conditions are met:

- Prior to the finalization of the WHMIS education and training, the joint committee or health and safety representative has the opportunity to review and provide information or advice on the entire education and training component, including its content, structure, and means of implementation. Content means education in "how WHMIS works," education in the hazards of hazardous products, and training in work procedures as itemized in section 5.7(1) of the Regulation. Means of implementation includes the choice of instructors and the use of any in-course evaluation.

- After initial implementation of WHMIS education and training, and at the time of each annual review of the WHMIS program, the employer asks for information and advice from the joint committee or health and safety representative on the effectiveness of the education and training.

Where a number of committees have been established by a large employer, an acceptable arrangement is for the central committee, where there is one, to review the employer's general plan for WHMIS education and training in all workplaces, and for local committees to review the WHMIS education and training in the areas of their respective responsibilities.

G5.6 Worker education and training

Issued August 1999; Editorial Revision May 9, 2014; Editorial Revision consequential to August 4, 2015 Regulatory Amendment; Editorial Revision consequential to August 22, 2022 Regulatory Amendment

Regulatory excerpt

Section 5.6(1) of the OHS Regulation ("Regulation") states:

(1) An employer must ensure that general WHMIS education, as it pertains to the workplace, is provided to workers on the

(a) elements of the WHMIS program,

(b) major hazards of the hazardous products in use in the workplace,

(c) rights and responsibilities of employers and workers, and

(d) content required on labels and SDSs, and the significance of this information.

Section 5.7(1) of the Regulation states:

An employer must ensure that a worker who works with a hazardous product or may be exposed to a hazardous product in the course of the worker's work activities is trained in the following:

(a) the content required on a supplier label and workplace label, and the purpose and significance of the information contained on those labels;

(b) the content required on an SDS and the purpose and significance of the information contained on the SDS;

(c) procedures for the safe use, storage, handling and disposal of the hazardous product;

(d) procedures for the safe use, handling and disposal of the hazardous product contained or transferred in

(i) a pipe or a piping system including valves,

(ii) a process or reaction vessel, or

(iii) a tank car, tank truck, ore car, conveyor belt or similar conveyance,

(e) procedures to be followed where fugitive emissions are present if workers may be exposed to those fugitive emissions;

(f) procedures to be followed in case of an emergency involving the hazardous product.

Purpose of guideline

The purpose of this guideline is to provide a way to assess the effectiveness of a worker's Workplace Hazardous Materials Information System (WHMIS) education and training as it pertains to the workplace and the hazardous products to which that worker may be exposed.

Education and training assessment questions

What are the hazards of the hazardous product?

The worker's answer must reflect the possible adverse effects of the products or materials in question. This demonstrates an understanding of generic hazard information (education).

How are you protected from those hazards?

The answer must demonstrate the worker's understanding of proper procedures to follow for the use, storage, handling, or disposal of the product and the proper use of personal protective equipment. The answer must demonstrate knowledge of adequate workplace control of the hazard through engineering, administrative means, or the use of personal protective equipment.

What do you do in case of an emergency?

The answer must show the worker's understanding of procedures to follow in the event of a spill, release, fire, or poisoning involving the hazardous product, and include the use of personal protective equipment where applicable.

Where can you get further hazard information?

This question focuses on the worker's ability to gain access to the significant information provided on labels and safety data sheets (SDS). Workers must know how to interpret the supplier label, workplace label, and other means of identification applicable to the use of the product and how to obtain information significant to health and safety from the SDS.

G5.8-1 Supplier label

Issued August 1999; Retired May 9, 2014

G5.8-2 Supplier label: Labelling on leased or rented chemical application units

Issued August 1999; Editorial Revision May 9, 2014; Editorial Revision consequential to August 4, 2015 Regulatory Amendment

Regulatory excerpt

Section 5.8(1) of the OHS Regulation ("Regulation") states:

Subject to any exemptions from labelling requirements in the Hazardous Products Regulations and this Part, an employer must ensure that a hazardous product or the container of a hazardous product received at a workplace is attached or printed with a supplier label.

Section 5.8(3) of the Regulation states:

Subject to any exemptions from labelling requirements in the Hazardous Products Regulations and this Part, an employer must replace the label with either a supplier label or a workplace label if a supplier label applied to a hazardous product or a container of a hazardous product becomes illegible or is accidentally removed from the hazardous product or the container.

Purpose of guideline

The purpose of this guideline is to clarify the supplier responsibilities for labelling of hazardous products contained within an application unit, such as a solvent spray parts washer, where the unit is leased or rented to an employer and the supplier periodically empties the holding tank on the unit and recharges it with a hazardous product.

Supplier labelling responsibilities

Sections 13(1)(b) and 14(b) of the federal Hazardous Products Act (HPA) requires that a supplier apply a label to a hazardous product intended for use in a workplace, or to the container in which the hazardous product is packaged. The label must disclose the required information and display applicable hazard symbols.

An application unit is not exempted as a manufactured article under section 5.3(3)(c) of the Regulation (section 12(i) of the HPA) because workers are likely to be exposed to the hazardous product during normal conditions of use. The supplier must provide and apply a supplier label on the leased or rented unit. If the label becomes illegible or is accidentally removed from the application unit, the employer must provide and apply a workplace label or a supplier label as required by section 5.8(3) of the Regulation. The supplier should be asked to provide a new supplier label as soon as practicable.

G5.8-3 Laboratory sample shipments containing at least two different hazardous products

Issued August 1999; Editorial Revision May 9, 2014; Editorial Revision consequential to August 4, 2015 Regulatory Amendment

Regulatory excerpt

Section 5.8(1) of the OHS Regulation ("Regulation") states:

Subject to any exemptions from labelling requirements in the Hazardous Products Regulations and this Part, an employer must ensure that a hazardous product or the container of a hazardous product received at a workplace is attached or printed with a supplier label.

Purpose of guideline

The purpose of this guideline is to clarify the requirements for laboratory sample shipments containing at least two different hazardous products.

Laboratory samples

Part 5 of the Hazardous Products Regulations specifies, amongst other requirements, the packaging of a laboratory sample of a hazardous product which may be exempt from the application of paragraph 13(1)(b) or 14(b) of the Hazardous Products Act. Section 3.5 of the Hazardous Products Regulations provides an exemption for the labelling of at least two different hazardous products in a single outer container.

The following procedures will satisfy supplier and employer responsibilities for labelling sample shipments containing at least two different hazardous products to an outside laboratory:

- The supplier ensures the outer container bears a Workplace Hazardous Materials Information System (WHMIS) supplier label. The label must provide, in addition to other required information items, the identity of all hazardous products known or suspected to be contained in the enclosed samples.

- The supplier ensures the container is provided with a lab analysis requisition form or equivalent which describes which inner containers contain, or are suspected to contain, hazardous products. If a requisition form does not call for analysis of the hazardous product in question, specific information on the ingredient must still be provided. For example, a blood sample submitted for a white cell count from a patient infected with hepatitis, must be accompanied by information on the microorganism.

- The supplier and employer establish an agreement in writing which covers the above two points and provides the employer's assurance of the following:

- Neither the samples nor any supplier information will be removed from the outer container prior to physical receipt by the lab department within the organization which receives shipment

- An information system is established in the lab, which ensures that each lab worker who could be exposed to a hazardous product in any inner container knows the information, which would otherwise be required on a WHMIS label applied to the inner container. This could be accomplished, for example, by informing the worker about the supplier identifier and emergency number combined with a means of identifying the specific hazardous ingredient in the lab sample.

G5.14-1 Supplier safety data sheet (SDS)

Issued August 1999; Retired May 9, 2014

G5.14-2 Fees

Issued August 1999; Editorial Revision consequential to August 4, 2015 Regulatory Amendment

Regulatory excerpt

Section 5.14(2) of the OHS Regulation ("Regulation") states:

When a supplier SDS obtained under subsection (1) for a hazardous product is 3 years old, the employer must obtain from the supplier an up-to-date supplier SDS in respect of any of that hazardous product in the workplace at that time.

Purpose of guideline

The purpose of this guideline is to clarify when suppliers are not permitted to charge a fee for a safety data sheet (SDS).

Where fees are prohibited

If, under sections 13 or 14 of the Hazardous Products Act, a supplier is required to provide an SDS as a condition of sale or importation to a workplace, a supplier may not charge the purchaser a fee for the SDS. This applies to the SDS sent out with the first shipment or where an employer requests an updated SDS, in conformity with section 5.14(2) of the Regulation.

Where fees are not prohibited

However, where an employer is required to obtain an SDS for a hazardous product purchased prior to a supplier compliance point, legislation does not prohibit the supplier from charging a fee for an SDS. In addition, a fee may be legally charged where a supplier provides an SDS to an employer for product partially or completely exempt from Workplace Hazardous Materials Information System (WHMIS) pursuant to section 12 of the Hazardous Products Act (e.g., pesticides or restricted products being sold as consumer products). However, WorkSafeBC does not condone the practice of charging fees for an SDS in any circumstance. All instances of fees for an SDS are to be brought to the attention of the WHMIS Coordinator.

G5.15 Laboratory SDS

Issued August 1999; Editorial Revision May 9, 2014; Editorial Revision consequential to August 4, 2015 Regulatory Amendment

Regulatory excerpt

Section 5.15(2) of the OHS Regulation ("Regulation") states:

For the purpose of subsection (1), "produces" does not include the escape of a hazardous product from equipment or from another product nor does it include intermediate products undergoing reaction within a reaction or process vessel.

Purpose of guideline

The purpose of this guideline is to clarify the circumstances in which safety data sheets (SDS) are required for hazardous products produced and used by an employer in a laboratory.

Hazardous products used in laboratories

- Hazardous products produced for immediate use in a reaction or which are produced and consumed in a reaction do not require production of an SDS. Such hazardous products must be used immediately, be used in total, and be consumed entirely during the reaction.

- An SDS must be available as required by legislation on all hazardous products which are components of mixtures produced in laboratories.

- For mixtures other than those intended for immediate use, a new SDS for the mixture must be produced if either of the following occur:

- The hazard of the mixture is different from the hazard of the ingredients separately

- The precautionary information reported on the SDS for ingredients is in conflict (for example, a different type of protective gloves or respiratory protection is recommended for each individual component of the mixture)

A new SDS will not be required for dilutions with water and mixtures in which hazards and precautions are generally unchanged from those of the ingredients.

Guidelines - Part 5 - Containers and Storage

G5.22 Covers

Issued August 1999; Editorial Revision August 2004; Editorial Revision April 6, 2020; Editorial Revision February 3, 2022

Regulatory excerpt

Section 5.22 of the OHS Regulation ("Regulation") states:

If an open container of a hazardous substance could pose a hazard, the container must be kept sealed or covered when not in use.

Purpose of guideline

The purpose of this guideline is to outline that if an open container of a hazardous substance (as defined in section 13 of the Workers' Compensation Act) could pose a hazard, section 5.22 of the Regulation provides that the container must be kept sealed or covered when not in use.

Determination if a hazard is present

To determine if a hazard is present, an assessment should be conducted which takes into consideration the substance's chemical properties (such as flammability, stability, reactivity, incompatibility, corrosivity, and/or volatility) and physical properties (such as physical state — liquid vs. solid — boiling point, and/or freezing point). The container's stability should be considered (refer to section 5.25 of the Regulation and OHS Guideline G5.25), as well as the volume of the material relative to the room space.

Substances to cover

In general, the following substances should be covered when not in use:

- Flammable solvents

- Oxidizing agents

- Reducing agents

- Strong acids and caustics

- Volatile and toxic solvents

- Combustible liquids

G5.25 Storage practices

Issued August 1999; Editorial Revision January 1, 2009; Editorial Revision consequential to August 4, 2015 Regulatory Amendment

Regulatory excerpt

Section 5.25 of the OHS Regulation ("Regulation") states:

A hazardous substance must be stored in a designated area, in a manner which ensures that it will not readily fall, become dislodged, suffer damage, or be exposed to conditions of extreme temperature.

Purpose of guideline

The purpose of this guideline is to clarify the requirements for the storage of hazardous substances.

Storage requirements

Section 5.25 of the Regulation requires that a hazardous substance be stored "in a designated area, in a manner which ensures that it will not readily fall, become dislodged, suffer damage, or be exposed to conditions of extreme temperature." The term "suffer damage" includes damage to the substance resulting from chemical instability such as peroxidation, as well as exposure to light, shock, or vibration. Under section 5.24, incompatible substances must not be stored "in a manner that would allow them to mix in the event of container leakage, breakage or other such circumstance." For information on chemical stability and incompatibilities, the appropriate safety data sheet (SDS) should be referenced.

The general training and work procedure requirements of section 5.2(d) of the Regulation also apply.

Guidelines - Part 5 - Flammable and Combustible Substances

G5.27 Ignition sources - Combustible liquid normally used as fuel

Issued consequential to December 1, 2021 Regulatory Amendment

Regulatory excerpt

Section 5.27 of the OHS Regulation ("Regulation") states:

(1) When a combustible liquid normally used as fuel, a flammable gas or a flammable liquid is handled, used or stored, all sources of ignition must be eliminated or adequately controlled.

(2) For the purposed of subsection (1) sources of ignition include open flame, spark-producing mechanical equipment, welding and cutting processes, smoking, static discharge and any electrical equipment or installation that is not permitted under the B.C. Electrical Code for use in hazardous locations.

(3) If the work involves more than one employer, the prime contractor or, if there is no prime contractor, the owner must ensure that sources of ignition resulting from the work of one employer are eliminated or adequately controlled in any work area where a combustible liquid normally used as fuel, a flammable gas or a flammable gas or a flammable liquid is handled, used or stored by any other employer.

Purpose of guideline

The purpose of the guideline is to provide examples of "combustible liquid normally used as fuel" that when handled, used, or stored, must have all sources of ignition eliminated or adequately controlled in accordance with section 5.27 of the Regulation.

Examples of "combustible liquid normally used as fuel"

"Combustible liquid" is defined in section 1.1 of the Regulation as a liquid that has a flash point at or above 37.8°C and below 93.3°C. Requirements of section 5.27 apply to a combustible liquid normally used as fuel because of its risk of fire or explosion given its relatively low flash point that is approaching the flammable range.

Some common examples of combustible liquids normally used as fuel and their flash points ranges taken from safety data sheets of manufacturers include the following:

| Combustible liquids normally used as fuel | Approximate flash point ranges |

|---|---|

| Diesel | >40°C |

| Kerosene | 38-72°C |

| Jet fuel | 38-62°C |

To determine if a liquid is a "combustible liquid normally used a fuel," the flash point of the liquid is within the definition of combustible liquid and its use is normally as fuel. If a combustible liquid is normally used as fuel, then the requirements of section 5.27 would apply to that liquid regardless of how it is being used at that particular workplace.

For example, section 5.27 would apply to diesel fuel even when it is being used as a cleaning solvent because it is normally used as fuel.

Combustible liquids such as lubricants and frying oil are not included in the scope of this requirement because they are not normally used as fuel. These substances have a higher flash point and, therefore, a lower risk to cause a fire or explosion.

G5.27(2) Electrical Safety Act repealed

Issued August 13, 2008; Retired November 2, 2016

This guideline is no longer required.

G5.28 Bonding or grounding of containers - Ensuring effectiveness

Issued consequential to December 1, 2021 Regulatory Amendment

Regulatory excerpt

Section 5.28 of the OHS Regulation ("Regulation") states:

If a metallic or other conductive container is used to transfer a combustible liquid normally used as fuel, a flammable liquid or a flammable gas to another metallic or other conductive container, the containers must be electrically bonded to each other or electrically grounded while the liquid or gas is being transferred.

Purpose of guideline

The purpose of the guideline is to provide examples of methods used to ensure that the bonding or grounding methods are effective when transferring combustible liquids normally used as fuel, or flammable liquids or gases.

Metallic or other conductive containers

In accordance with section 5.28 of the Regulation, metallic or other conductive containers used to transfer combustible liquid normally used as fuel, as well as a flammable gas or liquid, must be bonded to each other or grounded while the liquid or gas is being transferred.

Grounding and bonding

Grounding and bonding are ways to safely dissipate static charge to control the hazard of an ignition of gases and vapours. There are differences between these hazard controls.

Bonding is the use of an additional independent connection method — such as the use of a steel wire — between two conductive objects when this cannot otherwise be ensured. Bonding equalizes the electrostatic charge between the conductive objects, preventing potentially dangerous static sparks between them.

Grounding is a type of bonding where the conductive object is connected to the earth, usually with a conductive wire. Unlike bonding, grounding equalizes the electrostatic charge to that of the earth, which is generally considered to have zero potential, therefore preventing a spark discharge to a grounded object.

Ensuring that bonding and grounding are effective

In accordance with section 5.27 of the Regulation, employers are required to ensure that ignition sources are eliminated or adequately controlled in workplaces where combustible liquids normally used as fuel and flammable gas or liquids are stored, handled, or dispensed. Bonding and grounding are ways to adequately control static discharge.

Confirmation is essential to ensure that the bonding and grounding are effective. Employers should use an electrical continuity tester to verify that the bonding or grounding connections are made and exist before work begins. There have been explosions where a bonding system was not checked for continuity and led to a fatality.

Methods to verify continuity include the following:

- Ensure permanent systems are designed and installed by a competent person, such as an electrical engineer or manufacture representative. The systems are applicable to large, fixed facilities that store, handle, transport and dispense large quantities of flammable liquids or fuels on a regular basis. These systems usually include fail-safe or self-checking equipment that will monitor continuity and arrest the process if grounding and bonding are lost.

- Use an electrical continuity tester to ensure that continuity exists in the grounding and bonding systems. A continuity test must be conducted by a qualified person in accordance with accepted industry practices and standards.

Employers should seek advice of a qualified person to ensure bonding and grounding are effective in controlling the ignition hazard associated with static electricity.

G5.30 Dispensing

Issued August 1999; Retired March 31, 2015

This guideline is no longer required.

G5.32 Manual cleaning - Work procedures

Issued June 26, 2014; Revised consequential to December 1, 2021 Regulatory Amendment

Regulatory excerpt

Section 5.32 of the OHS Regulation ("Regulation") states:

A flammable liquid must not be used as a manual cleaning solvent unless

(a) a thorough review of alternative solvents by the employer indicates that a suitable non-flammable substitute is not available,

(b) appropriate written safe work procedures are implemented to effectively control flammability and health hazards,

(c) the quantity of liquid used is minimized,

(d) the worker is instructed and trained in the safe work procedures, and

(e) the work procedures have been submitted to the Board.

Purpose of guideline

This guideline provides guidance on development of safe work procedures to WorkSafeBC under section 5.32 of the Regulation.

Content of safe work procedures

If a thorough review of alternative solvents shows that no suitable non-flammable substitute is available, the employer may use a flammable liquid as a manual cleaning solvent and must develop and implement safe work procedures that effectively control flammability and health hazards.

Safe work procedures should address the following applicable factors:

- Required storage location and conditions for the solvent, including transportation from one work site to another

- Labelling and signage requirements for storage and working containers

- Minimizing the quantities of flammable solvent used for manual cleaning

- Reference to the availability of the safety data sheet

- Means of elimination or control of all ignition sources during use and storage of the solvent, including ignition sources in workplaces of other employers where the solvent is being used

- Potential for migration and flashback of solvent vapours

- Requirements for bonding and grounding during storage and dispensing

- Control of hazards described in the safety data sheet, including:

- means of ensuring control of worker exposures to the solvent (e.g., exposure monitoring, ventilation, respiratory protection)

- required personal protective equipment (e.g., gloves, goggles, face shield, respirator)

- Instructions for safe use of the solvent, including prep work, location of use, means and method of application of the solvent, cleanup procedures, and waste disposal

- The procedures should also address how workers are educated on the hazards and trained on protective measures (e.g., fit-testing, drills, WHMIS)

- Incident response (e.g., spills, failure of ventilation, fire)

- Locations and availability of emergency supplies (e.g., fire control, spill control, eye-wash, first aid supplies and service)

These factors do not address all workplace hazards, and employers need to ensure that the health and safety program addresses all hazards. The procedures need to include consideration of protection for workers of the employer as well as any other workers present at a workplace where the flammable cleaning solvent is used.

The Regulation requires that workers are instructed and trained in the safe work procedures.

Guidelines - Part 5 - Substances Under Pressure

G5.38 Handling and securing containers

Issued August 1999

Regulatory excerpt

Section 5.38 of the OHS Regulation ("Regulation") states:

(1) A compressed gas cylinder must not be hoisted by a sling or magnet, dropped, subjected to impact, handled by the regulator or used as a roller or work support.

(2) A compressed gas cylinder must be secured to prevent falling or rolling during storage, transportation and use, and where practicable, must be kept in the upright position.

Purpose of guideline

The purpose of this guideline is to outline that section 5.38(2) of the Regulation requires that a compressed gas cylinder be secured to prevent falling or rolling during storage, transportation and use. Where practicable, the cylinder must be kept in the upright position.

Achieving compliance

Compliance with this section can be achieved by either of the following:

- Chaining the cylinders to a secure object (a method typically used by welding shops, machine shops, and other employers handling cylinders in relatively small numbers)

- Using the "interlock" method of storing cylinders (a method used by gas manufacturers, distributors, transfill depots, subdivisions and company depots, or other member companies of the Compressed Gas Association)

As shown in the Figure below (this is an overhead or "bird's eye" view), the interlock method consists of dovetailing the cylinders into a cohesive unit. This method is acceptable when cylinders are in an area shipping or receiving a large number of cylinders.

Guidelines - Part 5 - Controlling Exposure

G5.48-1 Table of exposure limits - Background information

Issued October 29, 2003; Revised February 11, 2004; Revised February 4, 2005; Revised September 1, 2010; Retired September 25, 2019

This guideline is retired as it was merged with G5.48-2.

G5.48-2 Exposure limits and the review process

Issued October 29, 2003; Revised February 11, 2004; Revised February 4, 2005; Revised April 29, 2005; Revised November 28, 2008; Revised July 1, 2009; Revised September 1, 2010; Revised May 1, 2013; Revised September 25, 2019

Regulatory excerpt

Section 5.48 of the OHS Regulation ("Regulation") states:

Except as otherwise determined by the Board, the employer must ensure that no worker is exposed to a substance that exceeds the ceiling limit, short-term exposure limit, or 8-hour TWA limit prescribed by ACGIH.

Section 5.1 of the Regulation defines ACGIH as follows:

"ACGIH" means

(a) the American Conference of Governmental Industrial Hygienists publication entitled Threshold Limit Values and Biological Exposure Indices, dated 2002, as amended from time to time, or

(b) The American Conference of Governmental Industrial Hygienists publication entitled Documentation of the Threshold Limit Values and Biological Exposure Indices, as amended from time to time;

Purpose of guideline

This guideline provides background information on exposure limits as well as outlines the review process WorkSafeBC follows for reviewing and revising exposure limits of chemical substances.

Background information

An exposure limit is a maximum allowed airborne concentration for a substance that no worker is to be exposed above it. These exposure limits may include an 8 hour time-weighted average concentration, a short-term (15-minute) exposure limit, or a ceiling limit.

An exposure limit is not intended to represent a fine line between safe and harmful conditions. In determining an exposure limit, it is not possible to take into account all factors that could influence the effect that exposure to the substance may have on an individual worker. Therefore, for all hazardous substances, regardless of any assigned exposure limit, the guiding principle is elimination of exposure or reduction to the lowest level that is reasonably achievable below the exposure limit.

Due to a wide variation in individual susceptibility, some workers may experience discomfort from some substances at concentrations at or below the exposure limit. Others may be affected more seriously by aggravation of a pre-existing condition, or by development of an occupational disease. Furthermore, other workplace contaminants may affect an individual's response. The effects of combined chemical exposures are often unknown or poorly defined.

Exposure limit review process

The ACGIH conducts scientific reviews of chemical substances with the purpose of confirming or revising existing Threshold Limit Values (TLVs). ACGIH publishes a list of new or revised TLVs annually. WorkSafeBC generally uses the TLVs established by ACGIH to determine exposure limits. Exposure limits that differ from the ACGIH TLVs are presented on the Table of Excluded Substances in OHS Policy Item: R5.48-1 which includes the following:

- Those substances for which a TLV is currently not considered feasible for B.C. workplaces

- Those substances, previously listed in the former Table 5-4 of the Regulation (prior to 2002), that had lower exposure limits than the corresponding ACGIH TLV at the time

- Those substances, previously listed in the former Table 5-4 of the Regulation (back in 2002), that the ACGIH does not currently have a TLV for

For general information on how WorkSafeBC determines exposure limits, refer to Regulating Chemical Exposure.

The procedure for adopting new or revised exposure limits is described in WorkSafeBC's Exposure Limit Review Process for Chemical Substances. For questions about the exposure limit review process, contact WorkSafeBC's Policy, Regulation and Research division.

WorkSafeBC maintains a Table of Exposure Limits for Chemical and Biological Substances which lists all substances with a B.C. exposure limit prescribed under section 5.48 of the Regulation. This table has been created for convenience to promote public awareness; however, it does not represent the official version of the exposure limits and designations. Although WorkSafeBC regularly updates the table as necessary, it does not guarantee the accuracy or completeness of the information in this table since the contents of the table are constantly being revised by ACGIH or International Agency for Research on Cancer (IARC). For questions about the Table of Exposure Limits, email WorkSafeBC's Prevention Practice, Quality, and Engineering department.

G5.48-3 Normal 8-hour work period

Issued originally as G5.48-2 August 1, 1999; Revised October 29, 2003

Regulatory excerpt

Section 5.48 of the OHS Regulation ("Regulation") states:

Except as otherwise determined by the Board, the employer must ensure that no worker is exposed to a substance that exceeds the ceiling limit, short-term exposure limit, or 8-hour TWA limit prescribed by ACGIH.

Section 5.1 of the Regulation defines "8-hour TWA limit:"

"8-hour TWA limit" means the time weighted average (TWA) concentration of a substance in air which may not be exceeded over a normal 8 hour work period.

Purpose of guideline

The purpose of this guideline is to explain a normal 8-hour work period as it applies to section 5.48 of the Regulation.

Computation of an 8-hour work period

For an 8-hour TWA, a normal 8-hour work period will generally refer to a routine shift length of no more than 8 hours, over which exposure to an air contaminant occurs. In computing the TWA breaks should be included if there is significant exposure during the breaks, but not otherwise. For example, in the case of a routine shift length of 8 hours with an additional half-hour or three quarter-hour lunch break, the 8-hour work period is the TWA period, if there is no significant exposure over the lunch break. If significant exposure occurs during the lunch break, then the work period should be considered more than 8 hours and the exposure reduction factors stipulated in section 5.50 need to be applied. Note that 15-minute paid breaks (such as coffee breaks) should be included in the exposure period.

Refer to OHS Guideline G5.50 for assistance in applying the reduction factors.

G5.48-4 Conversions for ppm and mg/m3

Issued originally as G5.48-3 August 1, 1999; Revised February 11, 2004; Editorial Revision September 21, 2012

Regulatory excerpt

Section 5.48 of the OHS Regulation ("Regulation") states:

Except as otherwise determined by the Board, the employer must ensure that no worker is exposed to a substance that exceeds the ceiling limit, short-term exposure limit, or 8-hour TWA limit prescribed by ACGIH.

Purpose of guideline

This guideline explains how to convert exposure limits between ppm and those in mg/m3.

Exposure limit conversions

The ACGIH's Threshold Limit Values and Biological Exposure Indices provides instructions for converting the exposure limit (8-hour TWA limit or STEL or ceiling) for gases and vapours from parts per million (ppm) to milligrams per cubic metre (mg/m3). This might be used in situations where a substance in measured or listed in milligrams per cubic metre and the Table of Exposure Limits for Chemical and Biological Substances lists that substance in parts per million.

To convert a known exposure limit in ppm to the equivalent exposure limit in mg/m3, use the following formula:

| Exposure limit in mg/m3 | = | (limit value in ppm)(gram molecular weight of substance) | ||

| 24.45 |

Conversely, the following formula converts a known exposure limit in mg/m3 to the equivalent exposure limit in ppm:

| Exposure limit in ppm | = | (limit value in mg/m3)(24.45) |

||

| gram molecular weight of substance |

Molecular weights can be found in the NIOSH Pocket Guide to Chemical Hazards, chemical supplier lists, the NIST Chemistry WebBook or other online databases.

The numeric value of 24.45 in both formulae is the molar volume of air in litres at normal temperature and pressure (NTP), which is considered to be 25ºC and 1 atmosphere (101.325 kPa or 760 mm Hg or 760 torr). Note that this is not the same as standard temperature and pressure (STP), which is 0°C and 1 atmosphere.

If when dealing with measurements at NTP then it is necessary to calculate the molar volume of air for a temperature and pressure other than NTP and substitute this calculation for 24.45. Methods for calculating molar volumes can be found in standard occupational hygiene reference books such as those listed in OHS Guideline G5.53-4.

G5.48-5 Welding fumes

Issued originally as G5.48-4 August 1, 1999; Revised February 11, 2004; Revised August 3, 2006; Editorial Revision January 1, 2009; Editorial Revision consequential to August 4, 2015 Regulatory Amendment; Preliminary Revision March 14, 2024

Regulatory excerpt

Section 5.48 of the OHS Regulation ("Regulation") states:

Except as otherwise determined by the Board, the employer must ensure that no worker is exposed to a substance that exceeds the ceiling limit, short-term exposure limit, or 8-hour TWA limit prescribed by ACGIH.

Purpose of guideline

This guideline explains that welding fumes are of variable composition and provides information on substances that may be present. It also discusses the sources of information on welding fumes and how to determine applicable exposure limits. The term "welding" includes thermal cutting and allied processes such as brazing.

Welding fume composition

Establishing a worker’s exposure to hazardous substances in welding fumes is not a simple matter since this depends on the material being welded as well as the process and electrodes being used. Welding fumes may contain fluoride, and metals or oxides of metals such as aluminum, antimony, arsenic, barium, beryllium, cadmium, chromium, hexavalent chromium, cobalt, copper, iron, lead, manganese, nickel, silver, tin, titanium, vanadium, and zinc.

Apart from welding fumes, hazardous levels of gases — including carbon monoxide, oxides of nitrogen, or ozone — may also be present during welding. In addition, there may be a risk of asphyxiation when shielding gases such as argon are used, particularly in an enclosed or confined space. Decomposition products such as phosgene can form when coatings or residues on or near the object being welded are heated.

Sources of information on welding fumes

To determine the potential level of exposure to welding fumes, a systematic review of the base metal, consumables, and type of process is required. Typically, information on consumables is identified by reviewing documents such as the safety data sheets (SDSs) from the manufacturer. Other information, such as the composition of the metal(s) being welded or cut, the specific type of welding process, and other relevant information (e.g., current and voltage) should be gathered to assess the hazardous ingredients and expected products of reaction and decomposition.

Exposure limits

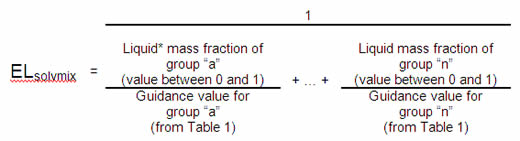

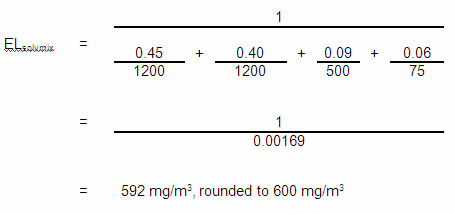

Once the information on possible exposures has been determined, the Table of Exposure Limits for Chemical and Biological Substances should be consulted for the applicable exposure limit(s).